Catalog excerpts

CAN FORMING FOR ROUND DWI AND DRD FOOD CANS Technology that k eeps you ahead

Open the catalog to page 1

The CAN-O-MAT is a mature multi-function system designed to meet the technical and commercial canmaking challenge of the future. l High level of process capability High level of modularity Wide variety of application Safety and operator protection CAN-O-MAT 2PC Multi-function system Spin flanging Rail-to-roll beading Light testing Swing flanging Combined machine system for all forming and light testing operations. The CAN-O-MAT 2PC is available from 1 to 4 station machine in any combination. The machine is plc controlled, is completely covered according to EU safety regulations and has a...

Open the catalog to page 2

Process for die forming of stacking necks l single die neck at the top side use of carbide or ceramic tools die necking is suitable for the precise necking of thin and hard material cheapest, fastest and most accurate necking process SPIN FLANGING Spin forming process for all cans and materials l active driven long life tool steel spins with carbide spins suitable for white lacquered cans low risk of flange cracks wide range of applications Spin flanging The bead profile and the beading process are responsible for the paneling and axial load of cans for processed food. The bead is formed...

Open the catalog to page 3

INTEGRATED FEATURES PERM AN EN T LU BE O I L FI LT E R I N G Lube oil filter • Reduces maintenance and downtime • Reduces oil consumption and machine wear • Filter contamination level is monitored • Ejection of individual can or an entire production sequence at the CAN-O-MAT outfeed for quality control • Test cans queued according to tool numbers and produced with production speed • No drop in production speed Access to the machine control via phone line to check fault messages and settings. BODY DIAMETER RANGE Automatic test can ejector Rail-to-roll beading Light testing Phone + 49 201 633...

Open the catalog to page 4All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

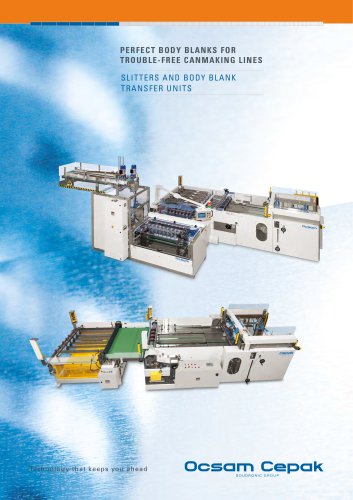

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages