Catalog excerpts

MACHINES FOR STAMPING, CURLING AND LINING FOR SHEET FEED ENDMAKING LINES Combined strength and precision the END-O-MAT multi-die stamping presses SOUDRONIC GROUP

Open the catalog to page 1

Combined machine system for medium and high-speed end production Downgauging with SR and with DR material – the key to stay competitive Since two thirds of the can costs are material costs, cost reduction has to be achieved mainly by reducing the material consumption: Downgauging of the tinplate for the ends and reducing the cut edge diameter of ends by using miniseams for thin and hard material, but not falling short of required end resistance values! (Buckle resistance, panel distension, pullback vacuum value) Material strength and thickness End geometry and method of production Seam type...

Open the catalog to page 2

MULTI-DIE PRESSES Minimal deformation of less than 0.01 mm (0.0004”): No parallelism errors, achieved by mechanically synchronised 4-point drive combined with hydraulically pretensioned press table (not welded into position) to maintain parallel alignment of the die set. Identical product over the entire die area l Advanced 4-point drive system dispenses with need for slide guiding system Quick retooling and quick resetting to different sizes Capable of producing ends with dia. Maximum sheet width of 1200 mm (47”) Excellent material utilisation thanks to minimal 2 H ydraulic pretension and...

Open the catalog to page 3

SHEET FEEDERS STRAIGHT SHEET OR COIL FEEDER Servodrive roll feed mechanism • The roller feed mechanism is controlled by servo motors which generate highly precise advance movements with an accurate, non-cumulative positioning • A digital servo controller ensures feed profiles with optimised acceleration - thin material can thus be accelerated smoothly and without slipping ZIG ZAG SHEET FEEDER Linear motor driven two/four axle drive • The coordinated traverse movements along the x and y axes is controlled by linear motors which generate highly precise advance movements • The sheet is clamped...

Open the catalog to page 4

TOOL ACCESS AND DIE SET CHANGE • The quicklift function provides comfortable and fast access to the die area at the convenient height of 1400 mm (55") • Spring-loaded rollers, which lift the tooling from the slide plate once the fixing screws have been loosened, allow the tooling to be changed easily and fast ADVANCED TOOLING SYSTEM STANDARD TOOLING SYSTEM for all common and non critical ends and shells •The end is drawn in one step • Suitable for SR and DR material • Suitable for easy profile geometry's • No mechanical springs for ejector blank holder and stripper ring •Tool operated by...

Open the catalog to page 5

OPTIONAL EXTRAS Using a special tooling carriage allows tooling changeover to be done by one operator in a very short time. System for heating up and cooling down the oil for constant oil and machine temperature in rugged climates. Tool changing carriage S H E E T L U B R I C AT I N G SYST E M Spraying or rolling system for lubricating the sheets in special cases. The stamped ends with initial curl are processed in a special disc curler between a fixed curling segment and a rotating curling disc. Its large diameter of approx.1085 mm for steel ends (approx. 850 mm for aluminium shells for...

Open the catalog to page 6

LINER High-speed rotary liner for all types of compound for double seam ends • Capacity between 300 epm and 2000 epm with 3-, 4-, 6-, or 8-fold tooling, diameter range between 46 mm (114) and 153 mm (603) • Operator-friendly menus with size-dependent parameter memory (accessed when changing to a different size) ► reproducible lined ends • Fine setting of lining guns (nozzle position) separately in radial and axial direction: In radial direction (diameter setting) by means of a threaded spindle, in axial direction (gun height) by means of a threaded spindle ► better compound placement...

Open the catalog to page 7

TECHNICAL DATAS OF THE PRESSES MATERIAL SIZES STRAIGHT SHEET FEEDING Max. size 1200 x 1150 mm / 47 x 45" END-O-MAT PRESS WITH 150 T TOOLING FOR ONE DIAMETER (DOUBLE ROW TOOLING) NOMINAL DIAMETER MAX. NO. OF DIES MAX. NO. OF STROKES/MIN. MM INCH SHEET FEEDING COIL FEEDING MATERIAL SIZES COIL FEEDING COMBINED TOOLING FOR TWO DIAMETERS NOMINAL DIAMETER MAX. NO. OF DIES MAX. NO. OF STROKES/MIN. MM INCH SHEET FEEDING COIL FEEDING MATERIAL SIZES ZIG ZAG SHEET FEEDING TOOLING FOR ONE DIAMETER (SINGLE ROW TOOLING) Mm. size 750 x 750 mm / 29 x 29" NOMINAL DIAMETER MAX. NO....

Open the catalog to page 8All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

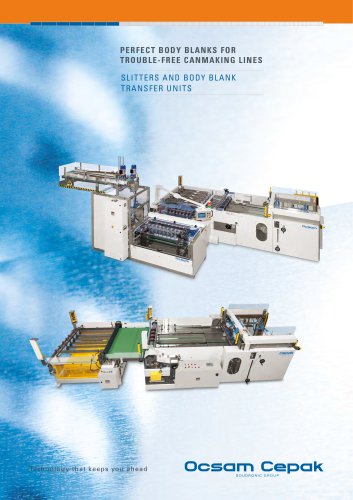

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages