Catalog excerpts

A flat belt transfers the stamped and curled ends to the upper end of a vertical spreader chute where they are accumulated. The lower end of the magnetic chute is provided with an end destacker. This enhanced version of the destacker also used for the CAN-OMAT system can destack 2,000 epm. An infeed starwheel then feeds the destacked ends to the lining chucks where they are accelerated to centrifugal speed. After the compound has been injected and distributed, the ends leave the machine at the end of the cycle on an outfeed belt. The lining chucks are driven separately by their own motor and are independent of the machine speed. The speed of the lining chucks reaches up to 4,500 rev./min. and can be individually adjusted to any end diameter and type of compound. The compound is injected by electronically controlled lining guns. Their needles are opened by solenoids and closed by springs. A second solenoid is provided for fine-setting of closing force and closing speed. The needle stroke can be set electronically from outside for each individual linig gun. Manually adjustable lining guns are available as an alternative. The lining guns can be set radially and axially to the end, independently of each other. The machine has a very operator-friendly den. Only the parameters for machine speed (dependent on line speed), spindle speed (dependent on end diameter and type of compound), number of lining rotations and centrifugal rotations need to be entered at the operating panel. There is no necessity to calculate times. To determine the quantity of compound for a given compound pressure and nozzle diameter, the needle stroke of each gun can be adjusted individually. The needle closing behaviour can be influenced by individual setting of the closing force. The hood can be lifted and allows good access for setting and cleaning.

Open the catalog to page 1All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

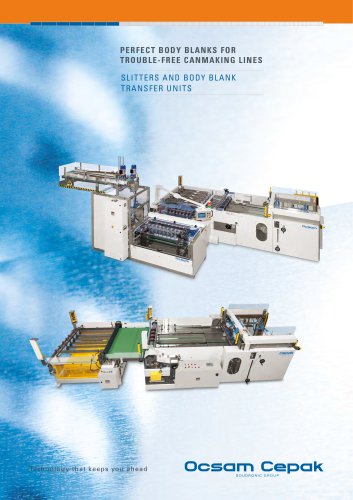

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages