Catalog excerpts

INLINE TACTILE MARKING UNIT TO PERFORM TACTILE MARKING FOR DANGEROUS PRODUCTS EMBOSS YOUR AEROSOL CANS ACCORDING TO THE EUROPEAN STANDARD. Significant savings: no more warning stickers required Compact machine : easy integration on existing lines User-friendly control panel Modular: possibility to replace the tactile triangle mark with any embossing logo

Open the catalog to page 1

TACTILE MARKING SPECIFICATIONS ACCORDING TO THE EUROPEAN STANDARD EN ISO 11683 : Mark position Welding position SECTION Mini S = 1/2 H x B WHATEVER THE SHAPE OF THE SECTION Technical specifications of the inline tactile marking unit Position of the machine in-line after the body welder Position with regards to the weld seam Can height (mm) Maximum speed (cpm) Design Axess - © SABATIER SAS - 04/2011

Open the catalog to page 2All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

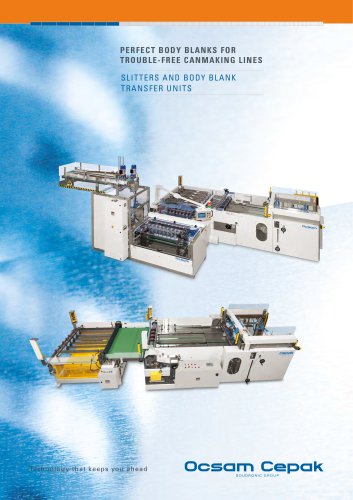

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages