Catalog excerpts

The END-O-MAT system is a combined machine system for medium and high speed end production. Processes, can/end requirements and machine requirements for thin and low cost cans and ends with high strength: Process Die-necking Can / End requirement high axial resistance: axial resistance is mainly determined by the necking angle Machine requirement steep neck angle smaller than 30 degrees neck re-forming by second necking operation interdependence of axial and paneling resistance adapted seam dimensions (SEFEL) m mini-flange mini-curl on the end sufficient resistance thanks to optimized geometry and sufficient countersink depth precise curling (mini-curl) beading method number of rotations and advanced bead depth forming bead geometries optimized by FEA calculation seaming method: number of rotations and advance seam forming only minor fluctuation of flange dimensions swing-flanging multi-die stamping press: rigid machine design multi-stage or thermo compensating tooling FEA optimized panel design disc curler: number of rotations

Open the catalog to page 1

END-O-MAT – the multi-die end production system with high capacity The END-O-MAT is not only a single stamping press for ends, but also an integrated high-performance system for the production of ends including curling, lining, drying, wrapping and palletizing. High performance means outputs of up to 4,000 ends per minute, depending on diameter, on a single system and with uniformly high quality. The essential prerequisites for such an endmaking system to obtain the best possible benefit are: Processing of all materials available on the market, either single- or double-reduced, tin- or...

Open the catalog to page 2

An end ejection system. Cam-controlled kickers eject the ends from the opened tooling. Each die is reached by a cross conveyor which takes over the end and deposits it on the outfeed belts. An end conveying system for uncurled ends to connect the END-O-MAT to the curlers. One (zigzag) or two (straight) high-speed curlers (depending on capacity) with large pitch circle diameter. An end conveying system for curled ends to connect the curlers and the lining machines. High-speed 3, 4, 6 or 8-head lining systems. End uprighting and conveying systems to connect liners and drying oven. End...

Open the catalog to page 3All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

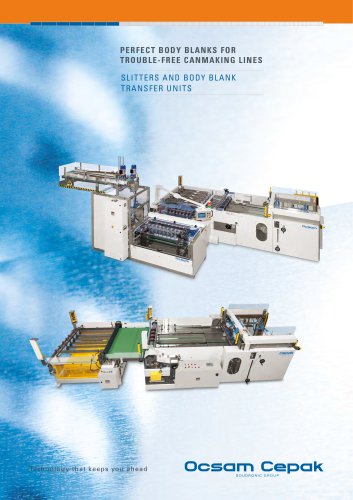

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages