Catalog excerpts

D OUB LE- LANE CURLER- LINER F O R I R R EG U LA R END S CURLIPACK SABATIER HAS SPENT 20 YEARS PERFECTING ITS CURLING AND LINING TECHNOLGIES TO OFFER CANMAKERS AN UNEQUALLED PRODUCT . . . . . . .. guarantees correct peripheral placement anD/or cut-edge distances OF the compound Technology that k eeps you ahead

Open the catalog to page 1

Can Release Position Bottom Seaming Top Seaming Beading Flanging Necking Food cans: Technical cans: PRODUCTION OF GEOMETRICALLY CONSISTENT CURLED SHELLS Club, Dingley and oval Nozzle lining: optimal peripheral placement of the compound Die-curling technology: production of geometrically consistent curled shells Top speed of 200 epm per lane thus matching the OF FERS even more fastest sheet feed presses which simplifies the implementation of connecting conveyors between FORME R cu rler- liner Rapid changeover between two formats at 150 epm Flexibility: deals with aluminium and steel shells...

Open the catalog to page 2All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

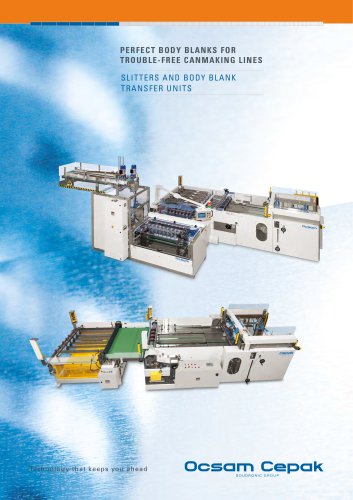

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages