Catalog excerpts

SOUDRONIC GROUP

Open the catalog to page 1

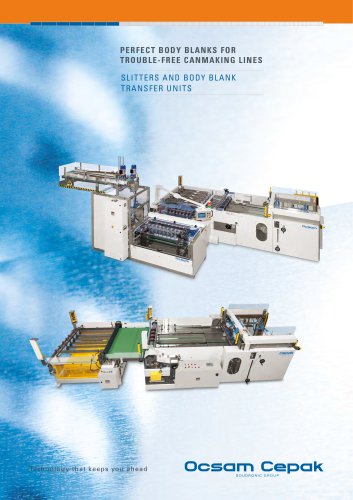

cutter-holder arbors with a tolerance of w 2 microns ensure perfect centering of the cutting equipment in any position. The cutter-holder arbors are supported at one end by pre-loaded angular contact ball bearings (without shaft axial float). No other support will be necessary while the equipment is being assembled. At the opposite end the cutter-holders are supported by needle bearings inserted in the appropriate removable bearing supports which speed up equipment replacement. The machine is specifically designed to be coupled with high capacity welding machines. It can be equipped with...

Open the catalog to page 2

C epak’s sheet feeder and a printing line sheet feeder Fitted with electromagnetic bar system for sheet support and sheet/strip drop at the exit of the first slitter. Electromagnetic strip drop bar system replaced the former chromium plated bars reducing the noise level during the drop. The slitter is also fitted with a policarbonate acoustic guard. Squaring of strip with respect to cutters by means of two, half-moon shaped, FFS. Two chains with wide, shock absorbing and spring-loaded teeth push the strip against Front Fingers Stop. Side strip positioning effected by eccentric bearing...

Open the catalog to page 3

The first slitter is equipped with system. This system allows the lateral adjustment of the sheet, using a (RM) graduated hand- wheel while the machinery is a time onto drop rails operated Double magnetic guide rails pre- vent the strips (sometimes bent) from bouncing during the drop first slitter is effected laterally by small rollers, with optional thrust, on the right or left side, which slide on saddles mounted on axial ball bearings and are controlled by mechanical cams. Rear alignment is effected by means of rotating pawls which can be adjusted while the slitter is in operation by...

Open the catalog to page 4

- Ȁ 0.03 mm. squaring accuracy depends on: - quality of tinplate - tinplate thickness - production speed - can size diameter - 110 mm. diameter chromium plated and ground cutter holder shafts, tolerance Ȁ 2 Micron - 172,5 mm. diameter tungsten carbide cutters, rapidly detachable on the right side - Cutter holder locking by means of a tie rod blank - “Mehanite” furnace stabilized cast iron machine base - 1.300 mm. slitter side barrier light - Stainless steel tables - Helicoidal gears in oil bath - Chromium plated and ground shafts and table supports - 3 HP motor single drive variable speed...

Open the catalog to page 6All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

Cepak Slitter Equipment

4 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages