Catalog excerpts

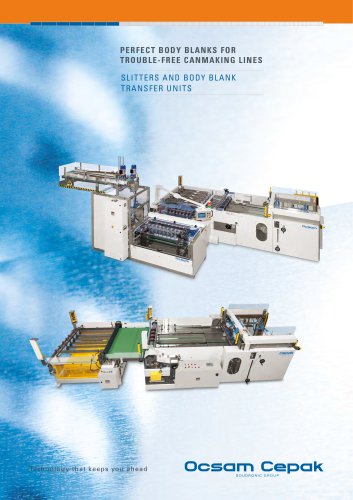

CEPAK small and flexible company able to offer customized solutions. More than 500 automatic slitter unites, 200 blank conveying systems and 20 robotic transfer systems operating worldwide. Hie best-performing and cost-effective machines in the market. SLITTER EQUIPMENT: Rubber guide rollers width 40-60 m/m - Cutter holder

Open the catalog to page 1

Three different types of stackers are available: Stacker suitable for big size strips/body blanks, maximum height of strip/blank package 400 mm. Stacker with pneumatic system suitable for medium-small body blanks. The packages stacked in a “sawtooth” shape, maximum height of a package 40 mm.

Open the catalog to page 2

Stacker recently designed, could be matched with a simple “universal” slitter. Fitted with a hydraulic lifting carriage. The strips/blanks, as in the above model, are stacked on a pallet. All duplex slitters could be fitted with: • Scrap conveyor • Electronic paint control panel “CT52/H” • Electronic micrometer for setting cutters • Cutter grinder • Squaring control plate BLADE GRINDER WITH DIAMOND ELECTRONIC MICROMETER With digital read-out for setting up the slitter cutters and checking the blanks. (With metric conversion or in inches).

Open the catalog to page 3

BODY BLANK CONVEYING SYSTEMS Several types of blank conveyors are available to suit various can production. Contact Cepak to find out which one is the most suitable for your requiremets. CHARACTERISTICS This type of conveyor, flexible and user friendly, covers a wide range of can sizes. The setting time for the height and the blank development is just 20 minutes. The final blank transportation to the welding machine hopper takes place on the upper part of the feed belt. This system prevents jamming due to the bent or corrugated blanks, it assures less critical hopper adjustments to lower...

Open the catalog to page 4All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages