Catalog excerpts

multi-function system integrated features au to m ati c botto m an d d o me co n veyi n g system • All kind of end feeding systems can be adapt- ed to the machine • Semi or fully automatic end feed systems are available • Gap controlled diabolo rolls feed the bottoms and domes to the de-stacking magazines • Weight control by the distribution unit • Reduces height changeover time down to one minute • Reproducible height setting • Quick lift function Can bo dy lu bri cati o n syst e m fo r di e n ecki n g • Canbodies roll along a lubricated felt strip to get a fine oil film on top and bottom edge • Motorized rolling drive • Minimized consumption of neck oil • Film weight controlled by the machine controller • Reduces maintenance and downtime • Reduces oil consumption and machine wear • Filter contamination level is monitored Phone + 49 201 633 1461 E-Mail info@cantec.com S ubject to mo dification 10 0 0 E 02.12 , print ed in Swit ze rland • Motorized height adjustment for all stations © Copyrig ht by Cant ec G mbH & Co. KG, E ssen, Germany & Soudronic AG, Bergdietikon, Switzerland Technology that k eeps you ahead

Open the catalog to page 1

spin flanging The CAN-O-MAT is a mature multi-function system designed to meet the technical and commercial canmaking challenge of the future for the pro- Spin forming process for all cans and materials – low risk duction of aerosol cans. • High level of process capability • Active driven long life tool steel spins • High level of modularity • With carbide spins suitable for white lacquered cans • Wide variety of application • Minimized polygon effect by internal central • Safety and operator protection Can-O-Mat Aerosol • Low risk of flange cracks • Wide range of applications, especially...

Open the catalog to page 2All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

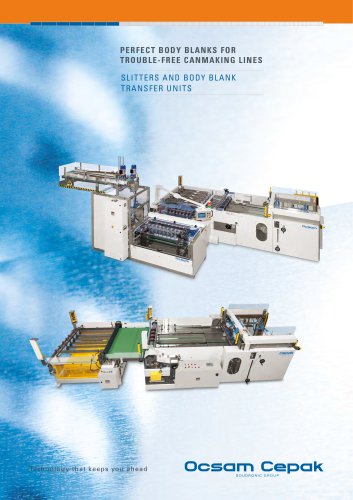

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages