Catalog excerpts

M E T A L P A C K A G I N G BODYPACK 1 TECHNICAL DATA OF THE BODYPACK 1 Volumetric capacity up to 5 liters Can diameters (mm)* 52 to 165 Minimum height (mm)* 60 Maximun height (mm)* 300 Maximun cycles/hour (single lane)** 9000 Maximun cycles/hour (double lane)** 18000 (two lanes running) * other sizes upon request. ** according to can diameter. MODULAR DESIGN : SEVERAL OPTIONS AVAILABLE GENERAL LINE MACHINE MANUFACTURER · 31, Avenue de Rome · F 13127 VITROLLES (FRANCE) Téléphone : 33 (0)4.42.46.94.00 · Fax: 33 (0)4.42.46.94.46 · E mail: mail@sabatier.org · www.sabatier.fr A SOUDRONIC COMPANY ADB COMMUNICATION - Subject to modification 2000 E 06.03 The pictures and drawings included in this leaflet are used for a general presentation. Only our offers define the contractual design of our equipment. Description and advantages The BODYPACK 1 is a new machine design achieved by valorization of more than 30 years experience and the very latest technologies of automation. It is a COMPACT machine with positive transfer of the bodies and vertical working station without elevators or complicated conveyors : The floor space saving is important and the body cannot be damaged on the conveyors. The MODULAR design of the BODYPACK 1 enables to combine in a single machine several functions to meet specific can design requirements. The most important functions which can be integrated are : necking-in spin flanging or die flanging inside or outside curling beading bottom end seaming top end seaming expansion or shaping The BODYPACK 1 is a FLEXIBLE machine offering automatic diameter change-over and height adjustment in a few seconds. It’s electro-mechanical conception allows to operate the line without specific qualification of the operators at a very low noise level. The maintenance costs are reduced and the efficiency of the line is optimized to offer a high productivity level. The BODYPACK 1 is available in both single and double lane version. TYPICAL LAYOUT OF BODYPACK 1 WITH TWO SEAMING STATIONS BODYPACK 1 Die flanging process Spin flanging process A SOUDRONIC COMPANY COMPACT MODULAR FLEXIBLE Subject to modifications according to the precise can specifications. 1 2 3 4 5 6 M E T A L P A C K A G I N G Bobypack 1/2 Page 1

Open the catalog to page 1

M E T A L P A C K A G I N G M E T A L P A C K A G I N G Necking-in Double lane for fast diameter change-over Movable control console Bottom and top end feeding Flanging (die or spin) Curling Beading Safe beading Seaming conveyors available BODYPACK 1 WITH DOUBLE DIE FLANGING AND BOTTOM SEAMING BODYPACK 1/2 DOUBLE LANE FAST DIAMETER CHANGE-OVER BODYPACK 1 FOR BEADED CAN Example of complete Bodypack line with Soudronic Body welder 10 meters 8 7 9 1 2 3 6 5 4 1 Heavy fabricated steel frame annealed before machining 2 Inlet synchronization conveyor 3 Flanging station (die flanging or spin...

Open the catalog to page 2All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

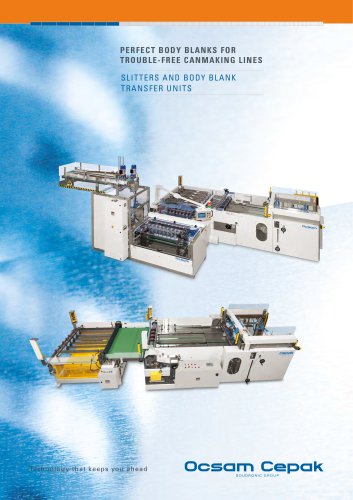

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

END-O-MAT Multi-die systems

8 Pages