Catalog excerpts

BENCHMARK I N M E TA L PA C K A G I N G PRODUCTION SYSTEMS Soudronic AG Industriestrasse 35 CH-8962 Bergdietikon Phone + 41 44 743 66 66 Fax

Open the catalog to page 1

GROUP OVERVIEW GROUP OVERVIEW METAL – A MODERN, VERSATILE PACKAGING MATERIAL . Metal cans are produced in a broad variety of shapes and sizes and used for every imaginable kind of food, aerosols and beverage. Because of the outstanding properties of metal packaging, cans, pails, drums or even irregularly shaped containers are often the packaging of choice for industrial and technical goods such as lubricants, paints, lacquers and aerosols. Although the production process is identical to food and beverage cans, the A STRONG COMMITMENT TO OUR CUSTOMERS AND SUPERIOR TECHNOLOGY . SOUDRON IC IS...

Open the catalog to page 2

GROUP OVERVIEW GROUP OVERVIEW A KEY PLAYER IN THE METAL PACKING INDUSTRY . We provide a complete range of machines and components – including slitters, THE FOLLOWING GROUP COMPANIES REPRESENT THE INDUSTRIAL CORE OF SOUDRONIC’S METAL PACKAGING OPERATIONS . SOUDRONIC IN SWITZERLAND. Located in Bergdietikon near Zurich, Soudronic transfer systems, welding machines, seam protection systems, bodyformers, two- in Switzerland is the industry’s premier source for canbody welders, seam piece can production lines and endmaking systems – to meet the requirements protection and curing systems, peel-off...

Open the catalog to page 3

COMPLETE PRODUCTION LINES FOR EVERY NEED . S OUDRON IC D ESI G NS, B UILD S, INSTAL LS A ND MAINTAINS FULLY INTEGRATED MANUFACTURING L IN E S W ITH PROD UCTI O N S P EE DS OF UP TO 120 0 CA NBO D IES PE R MIN UTE . A typical canbody production system consists of the following components: a slitter to cut the tinplate base material into body blanks of the required size, a transfer system, a canbody welder, a seam protection unit, a curing system to dry and harden the seam protection and a bodyformer to give the canbody its final profile and shape. The line will also include a unit to test...

Open the catalog to page 4

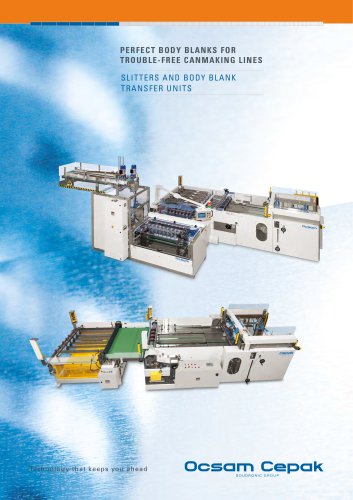

SLITTERS AND TRANSFER SYSTEMS . The slitter is the first stage in a three-piece canbody production line. It cuts the printed and lacquered base material – large square metal sheets – into body blanks INTO BODY BLANKS of the required size. The cut blanks are then fed into the canbody welder’s magazine from the slitter by a transfer system, which is indispensable in any fully automatic production line. Soudronic slitters and transfer systems, built by our subsidiaries Cepak WELD SEAM and Ocsam, easily satisfy demanding quality criteria such as versatility, precision, reliability, fast, simple...

Open the catalog to page 5

Once the raw canbodies leave the curing system, they are ready to be given their final shape and prepared for the endseaming process. Our highly flex- ible, fully automated bodyformers combine all the necessary functions in a single machine: shaping (mainly for optical purposes), necking (for good stacking properties after filling), flanging (necessary for the subsequent seaming process), beading (for additional stability) and seaming (of either the bottom or top end). Cantec’s bodyformers are a mature multi-function system designed to meet the technical and commercial canmaking challenges...

Open the catalog to page 6

A FULL RANGE OF DEEP-DRAWN CAN AND MULTI-DIE SYSTEMS . W E B U I L D A N D I N S TA L L P R O D U C T I O N L I N E S F O R D E E P- D R AW N C A N B O D I E S W I T H R O U N D, C O N I C A L , R E C TA N G U L A R O R I R R E G U L A R S H A P E S A S W E L L AS M U LT I - D I E P R E S S E S C A PA B L E O F S TA M P I N G A N D F O R M I N G U P TO E I G HT C A N S I N O N E S T R O K E . Developed and manufactured at Soudronic headquarters in Switzerland, our deepdrawing press systems are designed to stamp, predraw, final draw, emboss, panel and trim two-piece cans in a vast range of...

Open the catalog to page 7

PREFORMING OF TWO-PIECE SHELLS SHEET FEED PRESS: PREDRAW . The manufacture of two-piece canbodies places considerable stresses and strains on the material. To keep these within acceptable limits, bodies are generally made in two stages. In the first of these, the predraw press punches the blank into a basic, but as yet not final, cup shape. Soudronic’s predraw press is able to form four two-piece shells in a single stroke. The predrawn cans now move from the press onto a conveyor that takes them to the next stage. SHEET FEED PRESS: REDRAW AND TRIMMING . At the redraw stage, the canbody is...

Open the catalog to page 8

ENDMAKING SYSTEMS ENDMAKING SYSTEMS HIGH-QUALITY ENDS IN ALL SHAPES AND SIZES . SOUDRONIC'S ENDMAKING SYSTEMS, PRODUCED BY CANTEC IN GERMANY, USE STATE-OF-THE-ART TECHNOLOGIES TO GIVE YOU UNMATCHED EFFICIENCY AND FLEXIBILITY WHILE KEEPING YOUR PRODUCTION COSTS COMPETITIVE. Whether you need conventional ends or technically demanding peel-off lids, we supply turnkey solutions for both medium and high-speed applications. For high-speed endmaking, we use multi-die presses reaching output capacities of up to 4000 ends per minute. The curlers, liners, ovens and packing systems are all designed to...

Open the catalog to page 9

ENDMAKING SYSTEMS ENDMAKING SYSTEMS MULTI-DIE PRESSES FOR HIGH-SPEED ENDMAKING . Cantec’s multi-die press END-O-MAT is a high-performance multi-die production system for lids, easy open shells, rings, bottom ends and twist-off caps. Designed to meet the technical and commercial endmaking challenges of the future, this single-line system makes up to 4000 ends per minute (depending on diameter), all of uniformly high quality. It handles any type of material and minimizes scrap. STRIP-FEED PRESSES FOR MEDIUM-SPEED ENDMAKING . Whether the ends you are manufacturing are round or irregular, fully...

Open the catalog to page 10

PEEL-OFF ENDMAKING SYSTEMS PEEL-OFF ENDMAKING SYSTEMS PEEL-OFF ENDS OPEN UP NEW DIMENSIONS IN CONSUMER-FRIENDLINESS . A CONVENIENT ALTERNATIVE TO CONVENTIONAL ENDS, PEEL-OFF LIDS ARE INCREASINGLY IN DEMAND. OUR HEAT-SEALING ENDMAKING COMPONENTS ALLOW METAL PACKAGING PRODUCERS TO SATISFY MARKET DEMAND WITHOUT THE NEED FOR MASSIVE INVESTMENT. We developed peel-off ends for two and three-piece cans as a user-friendly alternative to easy-open ends. Peel-offs are suitable for dry, retortable and hotfilled products, do not spill or splash and are easily opened without additional tools or damage...

Open the catalog to page 11All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages