Catalog excerpts

METAL PACKAGING SYSTEMS AUTOMATIC DISPENSER INSERTION NEW MODULE FOR BODYPACK RANGE OF MACHINE INSERTION OF METAL OR PLASTIC DISPENSER AT 30 CPM n Significant labor saving n All operations performed with pails in vertical position Operation performed in 3 steps: Embossing and piercing of the hole Feeding and insertion of the dispenser 31, avenue de Rome - F 13127 VITROLLES A S O U D R O N I C G R O U P C O M PA N Y Design Axess - © SABATIER SAS - 03/2007 Bodyweld seam orientation

Open the catalog to page 1All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

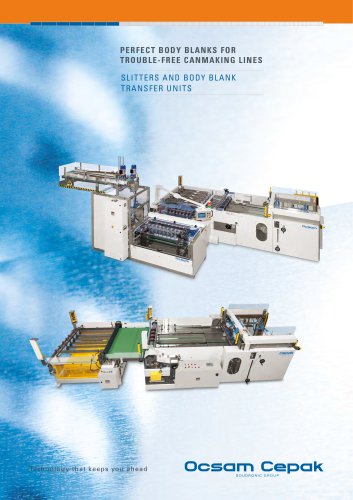

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages

Remove all

Compare up to 10 products