Catalog excerpts

advanced technology and services fast return on investment easy to handle, operate and maintain Technology that keeps you ahead Automatic canbody welders

Open the catalog to page 1

Canbod y We l d e r s Type SOUCAN 1090 FB SOUCAN 1080 FB SOUCAN 1075 AF SOUCAN 870 FB SOUCAN 860 AF Production max. [cpm]* 900 800 750 700 600 Body Diameter [mm] 52 – 99 52 – 99 45 – 154 52 – 99 45 – 154 Body Height [mm] 76 – 150 76 – 150 64 – 262 76 – 150 64 – 320 Sheet Thickness [mm] 0.14 – 0.25 0.14 – 0.25 0.14 – 0.31 0.14 – 0.25 0.14 – 0.31 Copper Wire Dia. [mm]* 1.24 / 1.38 1.24 / 1.38 1.24 / 1.38 / 1.5 1.24 / 1.38 1.24 / 1.38 / 1.5 Calibration Tool UNITOOL UNITOOL UNITOOL UNITOOL UNITOOL Welding Speed [m / min.]* max. 115 max. 115 max. 115 max. 90 max. 90 *Depends on can size and...

Open the catalog to page 2

Type AFB 118 AFB 115 SOUCAN 112 SOUCAN 110 SOUCAN 108 SOUCAN 106 Production max. [cpm]* 180 150 120 100 80 60 Body Diameter [mm] 45 – 113 45 – 113 65 – 185 65 – 185 65 – 185 65 – 185 Body Height [mm] 65 – 320 65 – 320 50 – 350 50 – 350 50 – 350 50 – 350 Sheet Thickness [mm] 0.16 – 0.3 0.16 – 0.3 0.18 – 0.31 0.18 – 0.31 0.18 – 0.31 0.18 – 0.31 Copper Wire Dia. [mm]* 1.38 / 1.5 1.38 / 1.5 1.38 / 1.5 1.38 / 1.5 1.38 / 1.5 1.38 / 1.5 Calibration Tool STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD Welding Speed [m / min.]* max. 42 max. 22 max. 25 max. 25 max. 25 max. 25 *Depends on can...

Open the catalog to page 3

SOUCAN 1090 FB SOUCAN 1080 FB SOUCAN 870 FB SOUCAN 1075 AF SOUCAN 860 AF AFB 118 / AFB 115 AFB 002 SOUCAN 650 / SOUCAN 640 SOUCAN 630 / SOUCAN 625 SOUCAN 620 SOUCAN 112 / SOUCAN 112-LT SOUCAN 110 / SOUCAN 110-LT SOUCAN 108 / SOUCAN 108-LT SOUCAN 106 / SOUCAN 106-LT

Open the catalog to page 4

F e at u r e s & O p t ions Soudronic Experience New Modular Design Improved Quality Control High Efficiency in Production Easy Operation & Maintenance Substantial Savings New Industrial Standards with High Reliability Available Options l Innovation combined with years of profound experience l Flexible machine concept, thus investments depending on your exact requirements l Machine components are interchangeable within the same machine family Optional weld monitors ensure a top - quality and reliable production. l Rapid change over of can heights and diameters l Instant restart due to...

Open the catalog to page 5

Technology that keeps you ahead Soudronic AG Industriestrasse 35 CH - 8962 Bergdietikon Phone +41 44 743 66 66 Fax +41 44 743 66 99 E-Mail info@soudronic.com www.soudronic.com Subject to modification 1000 E 04.11, printed in Switzerland © Copyright by Soudronic AG, Bergdietikon, Switzerland com p l e t e p rod u c t ion l i n e s Soudronic – a reliable par tner with more than 50 years of experience in designing and enginering resistance welding machines from lowes t to highest prod uction speds as wel as complete can prod uction lines. Soudronic 3-Piece Can Production Line

Open the catalog to page 6All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

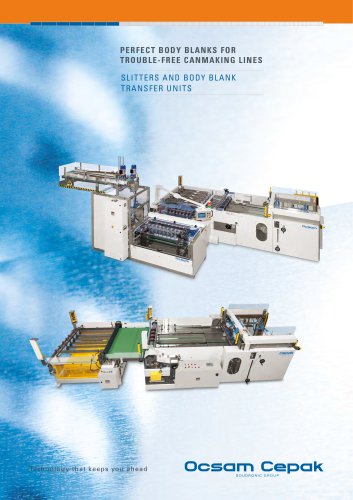

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages