Catalog excerpts

High-Temp Rod Ends/ Linkages Turbo & EGR Platforms & Beyond Prepared by: Chris Kaufman Director of Engineering Connecting a W orld in M otion

Open the catalog to page 1

High-Temp Rod Ends/ Linkages Standard Cablecraft® Linkage Design: • • Based on “6mm – ¼” Rod End family *Interchangeable Raceway (3 temperature ranges – See appendix) Natural Black (MGT), Blue Paint ID (UHT), White Paint ID (HGT) Adjustable or fixed CL’s for tamperproof designs Controlled breakaway torque Variable CL lengths Threaded or rivet studs for assembly Hex drive for threaded stud assembly Connecting a W orld in M otion *Custom Cablecraft® Race

Open the catalog to page 2

High-Temp Rod Ends/ Linkages Custom levers can be permanently fixed to the linkage ends to ease assembly to the actuator (input) shaft or Turbo/EGR (output) positioning shaft Alternate stud alignments allow for flexible positioning of sensitive equipment Connecting a W orld in M otion

Open the catalog to page 3

High-Temp Rod Ends/ Linkages High Temp Cablecraft® Linkages are designed to handle high temp gradients to help push sensitive electronics or other components away from the heat source. Prolonging life and reducing expensive cooling systems. Cablecraft® offers 3 Rod End Linkages systems that target different Temperature ranges: MGT: Continuous Operating Temp 232°C (450°F) UHT: Continuous Operating Temp 301°C (575°F) HGT: Continuous Operating Temp 343°C (650°F)

Open the catalog to page 4

High-Temp Rod Ends/ Linkages Performance Characteristics: • Composite Raceways • Effectively dampen vibration of engine environments that cause excessive wear in metallic joints • Allow for low friction movement, while keeping play at minimum • No need for high cost stainless heat treatment or specialty coatings • Rod end design allows for misalignment and reduced cost in component location criticality • Also eliminates concerns of binding from temperature deflection in fixed pin designs that can’t accommodate for misalignment • High strength material allows for high torque actuator usage •...

Open the catalog to page 5

High-Temp Rod Ends/ Linkages On Application (example) • Cablecraft’s® flexible design allows for remote actuator placement Connecting a W orld in M otion

Open the catalog to page 6

High-Temp Rod Ends/ Linkages Where used? Increased Fuel Economy & Performance • On-highway diesel vehicles • Farm/Construction equipment • Hybrid vehicles – EGR valves • Racing (turbo-chargers) • Material handling equipment High-Temp Applications • Food equipment • Industrial near heat source applications • HVAC Harsh Environments • Chemical plants • Power plants Confidential

Open the catalog to page 7

High-Temp Rod Ends/ Linkages Composite raceway’s absorb vibration generation from the application preventing accelerated joint degradation Lightweight design lowers mass acceleration that can impact connected components Linkage centerline can be custom length and alignment per application without large tooling impact Detachable connection point makes electronic actuator or turbo serviceable without removing entire unit (At lever arm or ball stud of rod end) Composite raceway design allows for use of standard high corrosion resistant steel without the use of expensive coatings or Heat...

Open the catalog to page 8

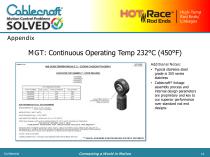

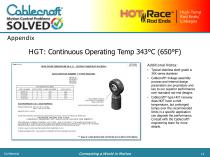

High-Temp Rod Ends/ Linkages Web Appendix MGT: Continuous Operating Temp 232°C (450°F) Est. max. overtemp condition: 282°C (540°F)* UHT: Continuous Operating Temp 301°C (575°F) Est. max. overtemp condition: 349°C (660°F)* Continuous Operating Temp 343°C (650°F) Est. max. overtemp condition: 415°C (780°F)* *TIME AT THIS TEMP IS TO BE LIMITED IN THE AMOUNT OF OCCURANCES (~ <0.5% OF TOTAL LIFE) AS WELL AS THE TIME OF EACH OCCURANCE. THIS EXPOSURE NEEDS TO BE VALIDATED PER APPLICATION AND CAN BE LOAD SENSITIVE THUS REDUCING THE TIME ALLOWANCE. CONSULTATION WITH THE CABLECRAFT® ENGINEERING TEAM...

Open the catalog to page 9

High-Temp Rod Ends/ Linkages MGT: Continuous Operating Temp 232°C (450°F) Additional Notes: • Typical stainless steel grade is 3XX series stainless • Cablecraft® linkage assembly process and internal design parameters are proprietary and key to our superior performance over standard rod end designs Connecting a W orld in M otion

Open the catalog to page 10

High-Temp Rod Ends/ Linkages UHT: Continuous Operating Temp 301°C (575°F) Additional Notes: • Typical stainless steel grade is 3XX series stainless • Cablecraft® linkage assembly process and internal design parameters are proprietary and key to our superior performance over standard rod end designs Connecting a W orld in M otion

Open the catalog to page 11

High-Temp Rod Ends/ Linkages HGT: Continuous Operating Temp 343°C (650°F) Additional Notes: • Typical stainless steel grade is 3XX series stainless • Cablecraft® linkage assembly process and internal design parameters are proprietary and key to our superior performance over standard rod end designs • Cablecraft® type HGT raceway does NOT have a melt temperature, but prolonged temps over the recommended limits in a specific application can degrade the performance. Consult with the Cablecraft® engineering team for more details.

Open the catalog to page 12All Cablecraft Motion Control catalogs and technical brochures

-

Throttle Pedal – Heavy Duty

2 Pages

-

Pull-Only Tension Controls

2 Pages

-

Connecting a World in Motion

84 Pages

-

Push-Pull Standard

4 Pages

-

Micro Adjust Control Heads

2 Pages

-

Non-Lock Control Heads

2 Pages

-

Twist Lock Industrial

2 Pages

-

Cablecraft Linkage

4 Pages

-

High-Temp Rod Ends/Linkages

4 Pages

-

Unidrum Lever

4 Pages

-

Push-Pull 4B

4 Pages

-

SR-G Ball Joints

2 Pages

-

COM-P Sperical Bearings

2 Pages

-

Leverstak

2 Pages

-

Micro Adjust Industrial

2 Pages

-

Button Lock Performance

2 Pages

-

Pull-Only T-Flex

2 Pages

-

Pull-Only Tension Cables

2 Pages

-

R-G Ball Joints

2 Pages

-

J/JM Sperical Bearings

2 Pages

-

DBM and DBF Rod Ends

2 Pages

Archived catalogs

-

Hardware/ End Fittings

4 Pages

-

DC/DH Control Swivels

2 Pages

-

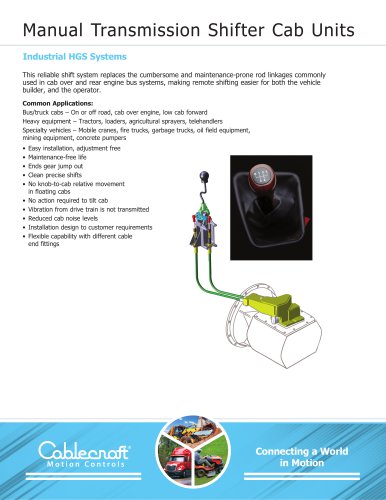

Manual Transmission Shifter

4 Pages

-

Hardware_End

4 Pages

-

Button Lock

2 Pages

-

Pull-Only Clutch

4 Pages

-

Custom Linkage Assemblies

2 Pages

-

DBM/DBF

2 Pages

-

Performance Push-Pull Cable

2 Pages

-

Push-Pull Cable - 4B

4 Pages

-

Pull-Only Cable - T-Flex

2 Pages

-

Pull-Only Cable - Tension

2 Pages

-

Pull-Only Clutch Cable

4 Pages

-

Custom Cable Assemblies

2 Pages

-

Hardware/End Fittings

4 Pages

-

Custom Hand Controls

4 Pages

-

Leverstack Hand Control

2 Pages

-

Unidrum Lever - METRIC

4 Pages

-

Undidrum Lever

4 Pages

-

Light Duty Lever

2 Pages

-

Brake Lever

4 Pages

-

Pull-Only Brake Cable

4 Pages

-

Push-Pull Cable - Standard

4 Pages

-

Linkage Assemblies - Custom

2 Pages