Catalog excerpts

UNIVERSAL GRINDING MACHINE WITH CONTROLLED MOVEMENT OF 1 - 4 AXES INNOVATIVE AND PRECISE The SMART PRO 500 CNC model, with its many variants, is the outcome of the continuous technological research, that has made Nesi a leader in its industry. To obtain design targets, rail with rolling friction have been installed on the longitudinal axis (working table) and transverse axis (carriage support head), with the dual benefit of smoother travel combined with increased working load. The electric spindle has a wide range of speeds, thus allowing accurate calibration for the best cutting result. Monolithic structure made of cast iron to ensure precision cutting with vibration absorption during machining. INTUITIVE • FANUC control. • Easy installation. • Safe and simple use. • Intuitive and customised user interface. TAILOR-MADE • Custom configuration. • Customisation of the software and of the mechanical specifications. • Machine designed to suit specific cutting requests. RELIABLE • Reduced wear of the components. • Quality guaranteed by years of experience and researc

Open the catalog to page 1

CHARACTERISTICS • FANUC control. • Brushless and torque motors (A) for high dynamic range of operations. High precision positioning on linear and rotative axes. • The longitudinal axis (working table) and the transversal axis (carriage support head) have rail with rolling friction. • Linear axis with re-circulation ball screws (grindind and preload) to reach high precision. • Driving axis A with technology"directdrive" for precision positioning. • All surfaces of support and contact are grinded. • Positioning system on the axes with optical lines and high resolution encoder directly...

Open the catalog to page 2

SMART PRO 500 UNIVERSAL GRINDING MACHINE WITH CONTROLLED MOVEMENT OF 1 - 4 AXES PROCESSING TYPOLOGIES The machines are available for grinding tools of every type. Examples of processing: •Cylindrical mills: cutting angle and first and second dorsal rake angle of both axial and radial cutting edges. •Taper mills: cutting angle and first and second dorsal rake angle on both axial and radial cutting edges. •Three edge mills: dorsal rake angles. •Taps: mating angle. •Countersink tool: angle on curved surface. •Given the extreme precision of the machines, it is possible to grind flat surfaces,...

Open the catalog to page 3

Longitudinal X axis - piece-holder table Longitudinal useful stroke [mm] Piece-holder table lenght [mm] Piece-holder table width [mm] Piece-holder table inclination on horizontal plane, micro-metric Transverse Z axis - head-carriage Transverse useful stroke [mm] Vertical Y axis - wheel centre head C€ Vertical useful stroke [mm] Vertical stroke of wheel centre spindle on sliding head [mm] Overall useful stroke [mm] Planetary base orientation on horizontal plane, radius Wheel centre head orientation on horizontal plane Rotating A axis - piece holder head Toolholder Speed of axes movement...

Open the catalog to page 4All CABE STOZZATRICI SRL catalogs and technical brochures

-

SIMPLE 500

2 Pages

-

VERTICAL BROACHING MACHINES

2 Pages

-

TABLE-UP BROACHING MACHINES

2 Pages

-

TOOLS

2 Pages

-

ST MANUAL

2 Pages

-

ST2 CNC & ST3 CNC

2 Pages

-

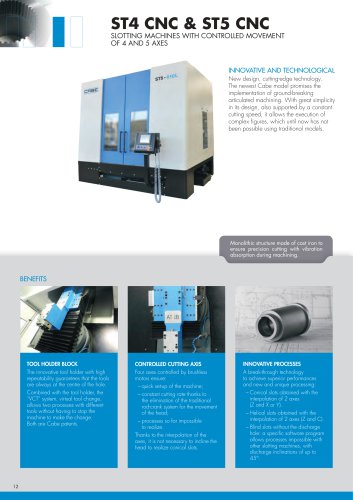

ST4 CNC & ST5 CNC

4 Pages

-

TTF CNC SERIES

3 Pages

-

Cabe Product Catalogue

19 Pages