Catalog excerpts

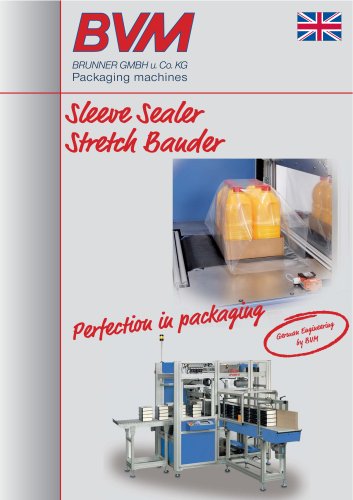

BRUNNER GMBH u. Co. KG Packaging machines Sleeve Sealer Stretch Bander Per ackaging c tion in p fe ering Engine n Germa by BVM

Open the catalog to page 1

BVM-Assembly Customers are the centre of all our business activities. Customers' requirements and demands guide us and each idea is seen as an opportunity. This openness to customers' wishes shapes our business; shared objectives merge our employees into a team. BVM Brunner is a privately-owned medium-sized company that started designing and building packaging machines in 1985. Today the company supplies high quality, innovative machines to the global packaging industry, and BVM Brunner's network of sales partners provides advice and support to companies worldwide. Our employees are the...

Open the catalog to page 2

Maintenance, repair, and refurbishment of used Training on customers' sites or in our factory Telephone support, provided by specifically trained v technicians with years of experience in resolving mechanical and electrical issues Advice on spares and consumables, sale of spares and Quick-response, global service team of in-depth trained service personnel High spare parts availability, guaranteed availability of BVM spares for a minimum often years

Open the catalog to page 3

Combo-Sleeve-Sealer The BVM Combo-Sleeve-Sealer is designed for production rates of up to 17 cycles/minute*. A sleeve sealer and a shrink tunnel are mounted onto a single frame. Single wound film is used to wrap a loose sleeve around the product, the sleeve is then shrunk tight to the product on its way through the shrink tunnel. 4 Possible configuration BMS 6030 L *depending on product and machine configuration

Open the catalog to page 4

Sleeve Sealer A BVM Sleeve Sealer uses single wound film to wrap a loose sleeve around a collation of products. Production rate is up to 45 cycles/minute*. A sleeve sealer can be configured to meet the requirements of a wide variety of packaging applications, for example, as a semi-automatic machine, as an automatic machine with right-angle pusher feeding, or as an automatic machine with in line product flow and infeed and outfeed conveyors. Special draw-off grippers are an option; they draw film off the reels when stacked products of different heights are randomly fed into a sleeve sealer...

Open the catalog to page 5

Stretch Bander A BVM Stretch Bander is designed for production rates of up to 30 cycles/minute*. A stretch bander seals a top and bottom film together to form a web. A collation is pushed against the web and the film is stretched tightly around the collation. A rubberised tension roller tensions the film, the level of tension is stepless adjustable. This enables the tight wrapping of stacked products and collations such as books, bottles or tins. In many applications the film of a tight wrapped product does not need shrinking, but - if required - the product can be moved through a shrink...

Open the catalog to page 6

are fitted with rod conveyors; the rods are coated with heat-resistant silicon rubber. with live rollers for use with Polyolefin or PVC films Infinitely variable ower airflow ensures optimised insulated heat adjustable from The set temperature is maintained accurately by a closed loop, digital temperature controller; the heating can be set at a

Open the catalog to page 7

0 depending on options fitted * servo-based seal bar drive Machine Designation: Shrink Tunnel Designation: right angle sleeve sealer Sleeve Sealer dual heating zones enhanced heating power TechnicalDate - Shrink Tuuuel 'depending on options fitted Insulation between heat chamber and outer housing is 100 mm© thick to prevent Heat resistant silicon curtains at tunnel entry and exit Whisper quiet blower motor *Bespoke dimensions on request heat loss RAL 1013 - Pearl White

Open the catalog to page 8

Operation Product feeding is either in-line with or at right angle to the product flow through a machine. Products can be collated in a machine or collated products can be fed to a machine. Both machines, stretch bander and sleeve sealer, seal a top and bottom film together to form a web. In a stretch bander, the front end of a product collation is pushed into the web to stretch the film before top and bottom film are sealed at the tail end of the collation to form a tight wrap. In a sleeve sealer, the film is not stretched, but wrapped loosely around the collation, while the collation is...

Open the catalog to page 9

Location Ferdinand-Lassalle-Straße 62 · D-72770 Reutlingen (Betzingen – Industriegebiet West) Telefon: (+49) 0 71 21/9 16 50 · Telefax (+49) 0 71 21/91 65 44 E-Mail: info@bvm-brunner.de Internet: www.bvm-brunner.de BRUNNER GMBH u. Co. KG Packaging machines 04/2012 Headquarters and production site: Fotos: Rainer Lebherz, Ofterdingen Our sales partner near you:

Open the catalog to page 10All BVM Brunner catalogs and technical brochures

-

Comtex 4G

1 Pages

-

Comtex 3G

3 Pages

-

Product Range

12 Pages

-

Compacta Genius

12 Pages

-

Compacta

12 Pages

-

Tray packer

8 Pages

-

Mailmaster

10 Pages