Website:

Burhani Engineering Technology

Website:

Burhani Engineering Technology

Catalog excerpts

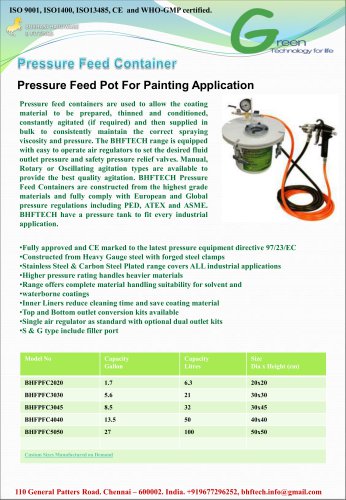

Cost Saving Vacuum and pressure in Same Machine A pressure pot for resin casting manufactured by Burhani Hardware And Fittings is required for bubble-free and air-trap-free resin castings. This is especially critical in creating clear resin castings applications, as trapped air can affect the appearance of a crystal clear casting. The BHFTECH Pressure Pot for resin is designed for use in applying pressure to force air out of resin and to force resin into thin sections of a mold. This eliminates air bubbles and air traps in the cured castings. Working Pressure is 100 PSI This is the best pressure pot for resin casting includes a gauge and all the other pneumatic fittings, valves and gauges . However, you will also need to purchase an air compressor of at least 3 H.P. and a ¼-inch adapter or coupling to attach the air compressor to the pot. Both items are readily available with Burhani Hardware and Fittings. Pressure Pot Specifications: Capacity as per below table How to use a pressure pot for resin setting up a pressure pot for casting resin under pressure is the best way to make high quality resin castings. This is especially true with difficult recesses and complex molds. Pressure casting compress air to sizes undetected by the human, creating a virtually bubble less casting. Simply cast your part in your mold and then insert your mold into the pressure pot. Secure the lid tightly, and then turn on your air supply to fill the pot to 50-100 PSI. (DO NOT EXCEED 150 PSI). Leave the pressure pot on until the casting has cured. Then remove the air source and release the air from the pot. Unfasten the lid and remove your mold from the pot. Note: You will want to make certain you do not pressure cast soft rubbers as the air bubbles will return once exposed to normal air pressure. You must use your burhani vacuum degassing chamber to remove all air from the mold rubber to avoid having the mold collapse in areas of your mold that have air trapped under the surface. You will have the appearance of warts on the surface of the finished result if you do not. using a pressure pot for resin : Mix your material in accordance with the directions and pour it into your mold. Place the mold into the pressure pot. Place the lid on the pressure pot and locate the (4) locking slots on the cover lining them up with the (4) swing up bolts on the tank. Place the (4) swing bolts into the slots in the cover and secure the (4) hand nuts tightly on the cover. Make certain the nuts are secured tightly before pressurizing the tank. CAUTION: DO NOT EXCEED 150 PSI Vacuum Degassing Chamber is used to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold when mixing resin and silicone rubbers and slower setting harder resins, a Vacuum Chamber is required. BHFTECH Pressure Pot Cum Degassing Chamber can help you for the above application You tube Video : https://youtu.be/GjYMKX20lNw Capacity Gallon Capacity Litres Custom Sizes Manufactured on Demand 110 General Patters Road. Chennai – 600002. India. +919677296252, bhftech.info@gmail.com

Open the catalog to page 1All Burhani Engineering Technology catalogs and technical brochures

-

Expoxy resin

1 Pages

-

Vacuum Glove Box Metal Body

4 Pages

-

Acrylic Vacuum Glove Box

2 Pages

-

Epoxy Resin

2 Pages

-

Vacuum Leak Test Chamber

2 Pages

-

Heated Vacuum Chamber / Oven

1 Pages

-

Vacuum Degassing Chamber

1 Pages