Website:

Burckhardt Compression AG

Website:

Burckhardt Compression AG

Catalog excerpts

REDURA PISTON SEALING SYSTEMS HETEROGENEOUS SYSTEMS

Open the catalog to page 1

Redura® Piston Sealing Systems

Open the catalog to page 2

Redura® Piston Sealing Systems Redura® Piston Sealing Systems Decades of experience in high-performance sealing systems Burckhardt Compression As a compressor OEM with more than 170 years of experience, Burckhardt Compression has been setting standards for piston packings and packing rings for decades. Patented designs developed in-house and extensive material research are the perfect recipe for unique high-performance piston sealing systems. This vast in-house tribology and material know-how forms the basis for the comprehensive product line Redura® for rings and packings. Redura® Piston...

Open the catalog to page 3

Redura® Piston Sealing Systems High-Performance Sealing Systems For every application – Upstream oil & gas – Gas transport & storage – Refinery – Petrochemical industry – Industrial gases – Food & beverage industry – Wood & charcoal industry – Mining industry – Power stations – ydro-electric power plants H – Nuclear power plants – ydrogen, nitrogen, argon, H helium – Hydrocarbons, ethylene, ethylene oxides – Chlorine, ammonia – Air, oxygen – Nitrous oxides, carbon dioxide, carbon monoxide, sulfur dioxide – ydrogen sulfide, hydrogen H chloride, sulfur hexafluorides, vinyl chlorides...

Open the catalog to page 4

Redura® Piston Sealing Systems Redura® Piston & Rider Ring Systems Careful Selection, Combination and Arrangement Make the Difference Double acting pistons – The piston sealing elements are only subject to the dynamic pressure component varying between the suction and discharge pressure. – The static pressure component is omitted due to the identical suction pressure at both ends of the piston. – For challenging applications like double acting compression of hydrogen, sealing rings with improved sealing efficency are recommended; this ensures longer life and sustained efficiency. – Robust...

Open the catalog to page 5

Redura® Piston Sealing Systems Redura® Piston Sealing Systems PUSHING THE LIMITS Rider ring Sealing rings

Open the catalog to page 6

Redura® Piston Sealing Systems pressure Breaker

Open the catalog to page 7

Redura® Piston & Rider Rings forming the winning team of rings Pressure breaker • In-house developed retained piston ring • Withstands the dynamic pressure component, and protects the subsequent sealing rings • Slope retained ring 1-piece, scarf joint • Built-up piston required • • Up to 250 mm (9.84 in) cylinder bore diameter • Slope retained ring 1-piece, gastight joint • Built-up piston required • • Up to 250 mm (9.84 in) cylinder bore diameter • Lubricated systems • ry-running systems: only vertical piston D arrangement • Single acting compression of gases with high molecular weight...

Open the catalog to page 8

Very robust sealing element preferred for lubricated systems and gas with high molecular weight Classical piston ring with specially designed, robust step-cut joint Extremely robust ring design for single acting compression of gases with high molecular weight • lassical scarf joint piston ring C • Dual use: – s pressure breaker (to withstand the A dynamic pressure component) – s piston sealing element, to handle A static pressure and seal the gas within the cylinder • Piston sealing element, to handle static pressure and seal the gas within the compression chamber • Twin piston ring R-type...

Open the catalog to page 9

sealing rings Robust ring design for double acting compression of gases with low molecular weight Patented ring design with improved sealing efficiency and durability for single acting compression of gases with low molecular weight For single acting compression providing high durability and sustained leakage tightness • Twin piston ring by-pass type • In-house developed • Highly efficient piston sealing element, to handle static pressure and seal the gas within the compression chamber • Twin piston ring coupled type • In-house developed and patented • Highly efficient piston sealing...

Open the catalog to page 10

rider ring PG 900 Advanced ring design provides reliable piston guidance, low thermal load and high durability • No sealing function due to by-pass grooves allows for lower friction, heat and wear • running systems Dry • Lubricated systems • Single and double acting – Single acting: rider ring positioned after the piston rings – ouble acting: rider ring positioned in D between piston rings • gas types All Specific properties • 1-piece, scarf joint, with by-pass grooves • Up to 1’200 mm (47.24 in) cylinder bore diameter • Classical scarf joint rider ring Depending on the specific...

Open the catalog to page 11

Redura® Piston Sealing Systems Redura® Burckhardt Compression Innovation From the idea to the finished product Burckhardt Compression covers the entire production process, from system engineering and material selection based on the application requirements to the final solution. We ensure highest quality at every step of the way due to our comprehensive in-house capabilities.

Open the catalog to page 12

Redura® Piston Sealing Systems

Open the catalog to page 13

10 Redura® Piston Sealing Systems Increase Availability with Redura® Rings and Packings

Open the catalog to page 14

Redura® Piston Sealing Systems Application Engineering Tailor-made system design for best performance System design C – omplete piston sealing system design – esign solutions for every application D – areful concept evaluation and selection based on C individual specifications – Material selection – In-house production capabilities for all ring designs and materials For piston sealing elements, pressure breakers, true sealing rings and rider rings, the following materials are primarily used: –– TFE-compounds (with appropriate fillers) P –– High temperature polymers (e.g. PEEK, PI with...

Open the catalog to page 15

Redura® Rings & Packings are characterized by Services the full range Burckhardt Valve Service Rings & packings Longest MTBO (mean time between overhaul) at lowest Leakage compressor Components Best Performance and Longest Lifetime Spare parts logistics Capacity control systems Field service Capital parts Technical support Labyrinth piston compressor components Revamps & upgrades Hyper secondary compressor components Condition monitoring & diagnostics Component repair Training Highest Availability Your local contact 23.17.14.40 – Printed in Switzerland on FSC certified paper Lowest Life...

Open the catalog to page 16All Burckhardt Compression AG catalogs and technical brochures

-

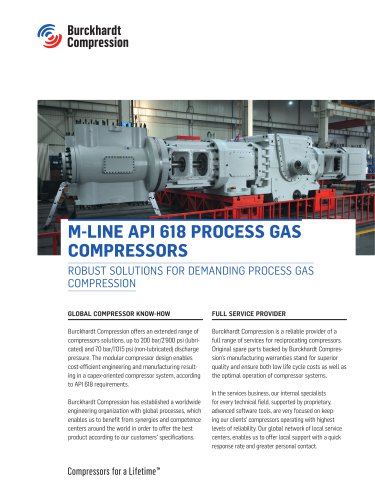

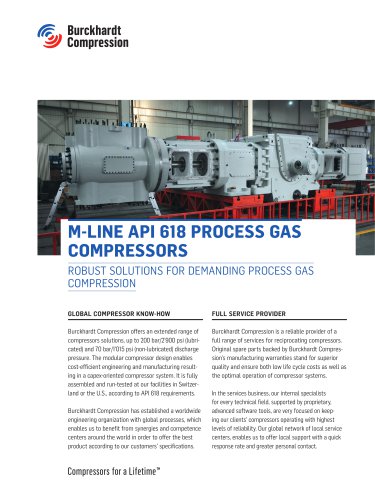

M-Line

2 Pages

-

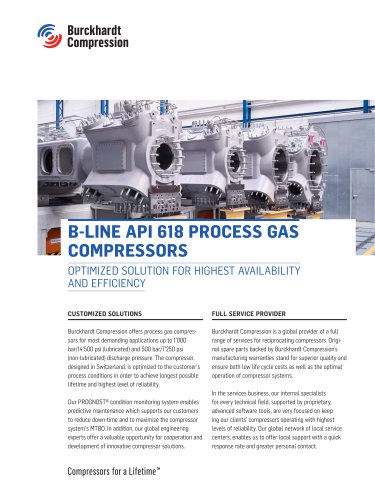

B-Line

2 Pages

-

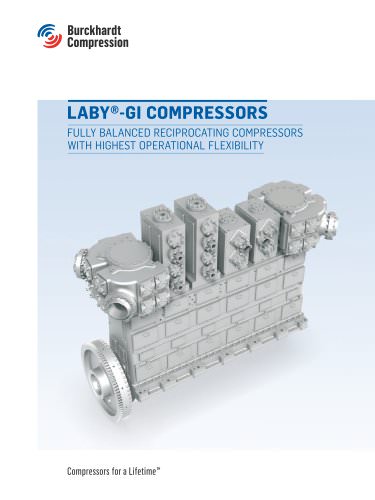

LABY®-GI

24 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages