Catalog excerpts

COMPREHENSIVE API 618 COMPRESSOR PORTFOLIO

Open the catalog to page 1

OVER 170 YEARS OF EXPERIENCE YOUR COMPRESSION SOLUTION PARTNER Burckhardt Compression is the worldwide market leader for reciprocating compressor systems and the only manufacturer and service provider that covers a full range of reciprocating compressor technologies and services. Its customized compressor systems are used in the upstream oil & gas, gas transport and storage, refinery, chemical, petrochemical and industrial gas sectors. Burckhardt Compression's leading technology, broad portfolio of compressor components and the full range of services help customers around the world to find...

Open the catalog to page 3

MARKETS AND APPLICATIONS FROM NATURAL GAS TO PROCESSING APPLICATIONS AND INDUSTRIAL GASES Pipeline booster Fractionating Reforming Catalytic cracking Dearomatisation Isomerisation Denitrogenation GASES HANDLED (INCLUDING CORROSIVE, EXPLOSIVE AND TOXIC COMPOSITIONS) CARBON DIOXIDE

Open the catalog to page 4

PETROCHEMICAL/ CHEMICAL INDUSTRY INDUSTRIAL GASES Carbon capture & storage Polysilicon production Ethylene oxide Ethylene glycol CARBON MONOXIDE HYDROGEN SULPHIDE HYDROGEN CHLORIDE

Open the catalog to page 5

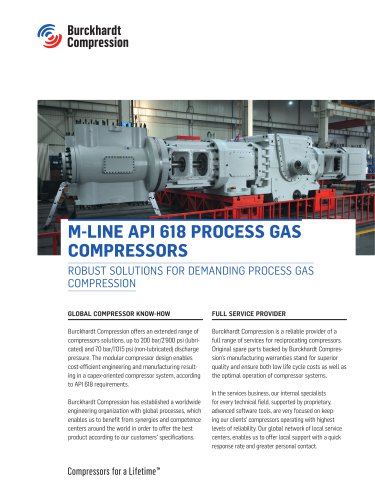

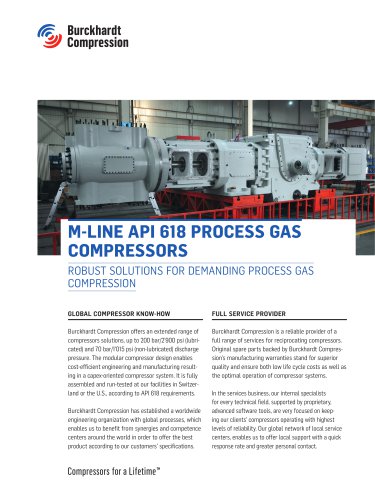

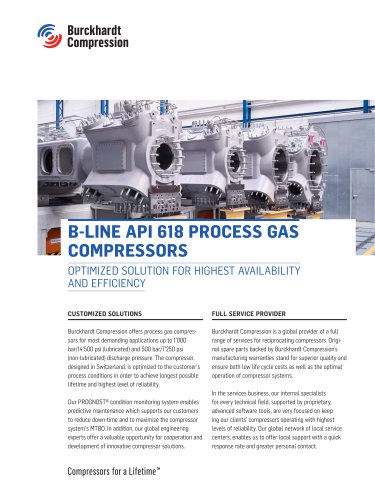

In addition to our premium B-Line API 618 Process Gas Compressors, which is specifically designed for lowest total cost of ownership (TCO). We offer a robust, modular and CAPEX-optimized API 618 Process Gas Compressors product line (M-Line). This enables Burckhardt Compression to offer a complete portfolio which covers the preferences of all our customers. B-LINE – PREMIUM & TCO-OPTIMIZED The Burckhardt Compression B-Line offers process gas compressors for most demanding and complex applications up to 1'000 bar/14'500 psi (lubricated) and 450 bar/6'530 psi (non-lubricated) discharge...

Open the catalog to page 6

WORLDWIDE REFERENCES RENOWNED TECHNICAL EXPERTISE 1 Hydrogen, discharge pressure 120 bara (1’740 psia), non-lubricated 12’000 h operation without maintenance 2 Carbon dioxide, discharge pressure 235 bara (3’400 psia). Transcritical compression cycle 3 Ethylene, discharge pressure 288 bara (4’177 psia). Main stream Process Gas Compressor without a stand-by compressor due to its high availability Guan Xinchun, Mechanical Maintenance Manager, CTM LDPE BASF-YPC Company Limited, Luhe istrict, Nanjing, China D “At our plant in Nanjing, we operate a Process Gas Compressor as booster/primary...

Open the catalog to page 7

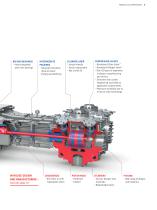

GUIDE RINGS - According to API 618 - Pressure relieved - Very long lifetime - Optimized mounting position PISTON RINGS - Decades of lubricated and non-lubricated experience - Various own designs and materials for maximum durability - Optimized wear compensation PISTON ROD PACKINGS - Applied technology based on decades of experience - Heterogeneous systems allowing high pressure non-lubricated services - Extremely high sealing efficiency and lifetime OIL SCRAPERS - Highly efficient oil removal - Material selection according to specific application - Long lasting design for minimum lube-oil...

Open the catalog to page 8

BIG-END BEARINGS – Interchangeable with main bearings IN-HOUSE DESIGN AND MANUFACTURING – FOR RELIABILITY INTERMEDIATE PACKINGS – Separates two-piece distance piece – Purging and buffering CROSSHEADS – One piece or with replaceable shoes CYLINDER LINER – Service-friendly – Easily replaceable – Not shrink-fit PISTON RODS – Hardened – Coated COMPRESSOR VALVES – Burckhardt Plate Valve™ – Burckhardt Poppet Valve™ – Over 120 years of experience in design, manufacturing and service – Selection and custom engineering according to application requirements – Maximum durability due to in-house valve...

Open the catalog to page 9

psia bara DIMENSIONS Type Vertical 1, 2, 3 and 4 crank BY and BS compressors are also available as CY and CS.

Open the catalog to page 10

M-LINE COMPRESSOR DESIGN ROBUST SOLUTIONS FOR DEMANDING PROCESS GAS COMPRESSION KEY COMPRESSOR COMPONENTS – FOR A CAPEX-OPTIMIZED COMPRESSION SOLUTION GUIDE RINGS – According to API 618 – Pressure relieved PISTON RINGS – Lubricated and non lubricated piston rings PISTON ROD PACKINGS – Non-purged / purged – Leak gas recovery – Water cooled – Rod drop sensor – Temperature monitoring RUGGED DESIGN – FOR DURABILITY LUBRICATION SYSTEM (NOT ILLUSTRATED) – According to API 618/614 or to customer requirements DISTANCE PIECES – Single- or two compartment – Vented – Purged – Drained OIL SCRAPERS –...

Open the catalog to page 12

CONNECTING RODS – Die-forged – Lubricated from crosshead side GLOBAL DESIGN AND MANUFACTURING – FOR RELIABILITY INTERMEDIATE PACKINGS – Separates two-piece distance piece – Purging and buffering CROSSHEADS – Three-piece crosshead acc. to API 618 – Exchangeable crosshead shoes – Easy access for inspection and maintenance COMPRESSOR VALVES – Burckhardt Plate Valve™ – Burckhardt Poppet Valve™ – Over 120 years of experience in design, manufacturing and service PISTON RODS – Hardened – Coated – Selection and custom engineering according to application requirements – Maximum durability due to...

Open the catalog to page 13

psia bara

Open the catalog to page 14

ONLINE CONDITION MONITORING AND SIL3 MACHINE PROTECTION MINIMIZE RISKS – MAXIMIZE UPTIME MONITORING THE CRUCIAL PARTS Preventing accidental breakdowns is vital. They can have serious consequences, such as risks for plant safety and the environment, production loss, expensive and time consuming repairs, etc. Burckhardt Compression recommends PROGNOST Systems – the technological leader in machine protection and online monitoring with more than 25 years of experience. Main measurements points for monitoring are: PROGNOST®-NT is an automated machinery diagnostic system incorporating SIL...

Open the catalog to page 17

UNEQUALED SERVICE CAPABILITIES FOR EVERY RECIPROCATING COMPRESSOR – mproved design to eplacement I r parts with excessive wear – recarious or unsafe operating condition P – Maintenance or spare parts logistic scheduling EVALUATION – oot cause analysis/failure analysis R – isk analysis R – ondition analysis C – aterial analysis M – easibility studies F – EA studies F – on-destructive testing (NDT) N – tock recommendations S ENGINEERING – n-site, and/or in-house measurements of O components – everse engineering R – Retrofit – ecalculation and dimensioning R – ngineering for repair procedures...

Open the catalog to page 18All Burckhardt Compression AG catalogs and technical brochures

-

M-Line

2 Pages

-

B-Line

2 Pages

-

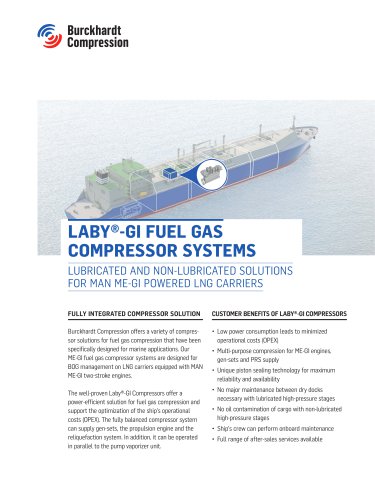

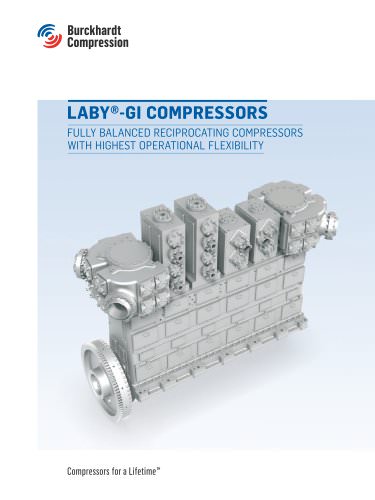

LABY®-GI

24 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Redura(R) Piston Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages