Website:

Burckhardt Compression AG

Website:

Burckhardt Compression AG

Catalog excerpts

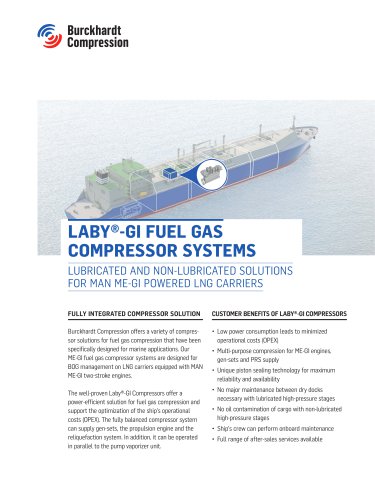

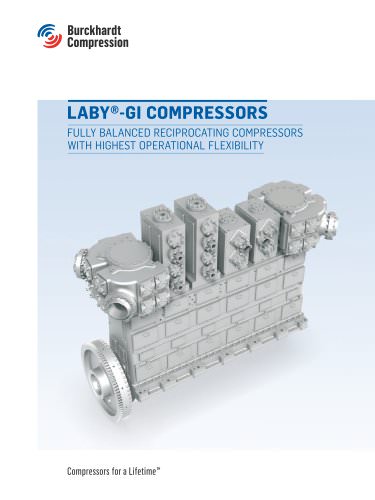

LABY®-GI COMPRESSORS FULLY BALANCED RECIPROCATING COMPRESSORS WITH HIGHEST OPERATIONAL FLEXIBILITY

Open the catalog to page 1

LABY®-GI COMPRESSORS MARKETS AND APPLICATIONS FROM OFFSHORE OIL & GAS TO PROCESSING APPLICATIONS INSTALLATIONS – LNG carriers – LNG FPSO – FSRU – Production platforms GASES HANDLED – Natural gas – Ethylene – Propylene – Mixed hydrocarbons CnHm APPLICATIONS – Boil-off gas handling – Fuel gas handling – Process gas handling – Minimum send-out on FSRU – Natural gas transmission – Relique

Open the catalog to page 2

LABY®-GI COMPRESSORS SPECIAL APPLICATIONS REQUIRING – Strict vibration limits – High discharge pressures up to 350 bara / 5’080 psia – Lubricated or non-lubricated gas compression – Handling of difficult or dangerous gas mix

Open the catalog to page 3

LABY®-GI COMPRESSORS LABY®-GI COMPRESSOR PURPOSE-BUILT FOR TOUGH OFFSHORE DUTIES Through detailed cooperation with recognized marine equipment and system suppliers, and the close relationship to well known end-users in the offshore market, Burckhardt Compression has developed a highly unique and flexible compressor solution that perfectly fits a wide range of individual customer requirements for highly demanding offshore applications. Traditional engineering and our decades of experience are the foundation of the vertical, in-line, 6-crank, low speed reciprocating compressor. The innovative...

Open the catalog to page 4

LABY®-GI COMPRESSORS UNIQUE CYLINDER SEALING SYSTEM – FOR LOWEST WEAR AND BEST PERFORMANCE Depending on the compression duty pressure and temperature requirements, we can offer either lubricated or non-lubricated cylinder sealing, allowing the selection of the very best technology according to individual stage process requirements. With the Laby®-GI Compressor we can provide cylinder configurations that fit your speci fications best. LABYRINTH SEALING – OIL-FREE AND CONTACTLESS COMPRESSION In the piston and piston rod gland many tiny throttling points create a friction-less sealing...

Open the catalog to page 5

LABY®-GI COMPRESSORS DESIGN FEATURES FOR MAXIMUM RELIABILITY AND SAFETY KEY COMPRESSOR COMPONENTS – FOR BEST PERFORMANCE AND LONGEST LIFETIME GUIDE RINGS – Pressure relieved – Very long lifetime – Optimized mounting position PISTON RINGS – Decades of experience with lubricated and non- ubricated gas compression l – Various proprietary designs and materials for maximum durability – Optimized wear compensation COMPRESSOR VALVES – Burckhardt Plate Valve™ – Burckhardt Poppet Valve™ – Manley® Valve, licensed by Burckhardt Compression – Over 120 years of experience in design, manufacturing and...

Open the catalog to page 6

LABY®-GI COMPRESSORS IN-HOUSE DESIGNED AND MANUFACTURED MAIN PARTS – FOR RELIABILITY HIGH PRESSURE CYLINDER ASSEMBLY – Lubricated ring sealing technology – Up to 350 bara / 5’080 psia discharge pressure – Cylinder with replaceable liner (no shrink fit) LOW PRESSURE CYLINDER ASSEMBLY – il-free labyrinth sealing system between O piston and cylinder and along the piston rod gland – For low temperatures down to –160 °C (–256 °F) – nsensitive to extreme variation in suction I temperature – Up to 100 bara / 1’450 psia discharge pressure – Contactless – No-friction – No wear – Cylinder integrated...

Open the catalog to page 7

Discharge pressure bara / psia Special applications above 350 bara possible LP190: 5 stages^ LP250: 5 stages TECHNICAL DATA AND DIMENSIONS Type 11 designed for three operating points: 3'000, 3'500 and 4'000 kg/h / 6'600, 7'700 and 8'800 Lbs/h 2) approximate data: depends on specific contract execution 3) allows an extra 2'200 mm / 87 in for maintenance Special package designs upon request.

Open the catalog to page 8

LABY®-GI COMPRESSORS Illustrated package shown without pressure piping and upper steel structure

Open the catalog to page 9

BEST SUITED FOR ALL KINDS OF PROCESS GASES AND PARAMETERS The uniqueness of the Laby®-GI Compressor is also reflected by its flexible performance range allowing very simple operation and control. No other compressor can be operated as efficiently over such a wide range of process duty parameters. For example, the discharge pressure necessary for fuel gas system supply, is automatically available independent of: - Alternating suction gas conditions: ■ Temperature (neither pre-heating of the gas nor pre-cooling of the compressor is necessary) ■ Pressure ■ Composition (e.g. N2 content in...

Open the catalog to page 10

LABY®-GI COMPRESSORS WARM START-UP DIAGRAM OF A LABY®-GI COMPRESSOR WITHOUT SPECIAL CONTROL NOR PRE-COOLING OF THE COMPRESSOR °C / °F 100 / 212 Discharge temperature second stage 0 0 Discharge temperature first stage Suction temperature first stage –150 / –238 Time SIMPLE CAPACITY CONTROL CONCEPT WITH APPROXIMATE PROPORTIONAL RATIO OF MASS FLOW AND SHAFT POWER FOR HIGH TURN-DOWN EFFICIENCY OF THE LABY®-GI COMPRESSOR The red dotted curve shows the performance of the capacity control on a turbo compressor, typically realized with adjustable inlet guide vanes. This arrangement allows an...

Open the catalog to page 11

Laby®-GI Compressor package installed between the first two spherical LNG tanks on a FSRU

Open the catalog to page 12

SIMPLE COMPRESSOR DESIGN AND PROVEN TECHNOLOGY REDUCE YOUR COSTS FROM INSTALLATION TO SERVICE Remote locations, harsh seas, extreme climates, highly corrosive environment, difficult gases, customization and constraints, weight and dimensions – these are just some of the basic characteristics of offshore projects. Burckhardt Compression and the simple and robust design of the Laby®-GI Compressor accept all these challenges. The combination of simple design features and proven technology have created a compressor solution which is capable to cope with this tough offshore environment. The...

Open the catalog to page 14

Simple control concept and system Good accessibility to all service components – Integrated control system as part of the ship control – Very easy start-up and shut-down procedures that only requires aa minimum training of the crew – Simple mechanical maintenance procedures for reciprocating machinery can be carried out by the

Open the catalog to page 15All Burckhardt Compression AG catalogs and technical brochures

-

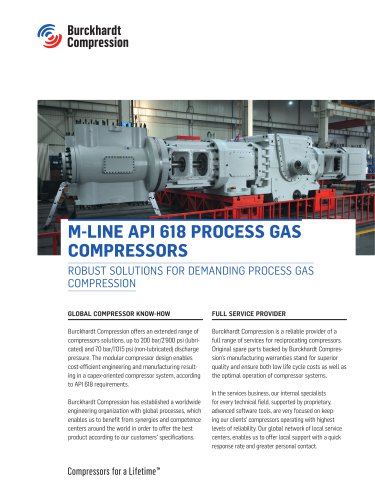

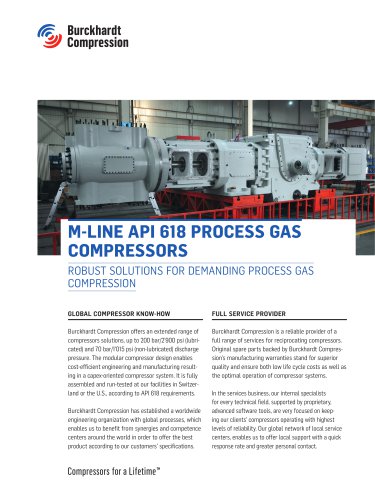

M-Line

2 Pages

-

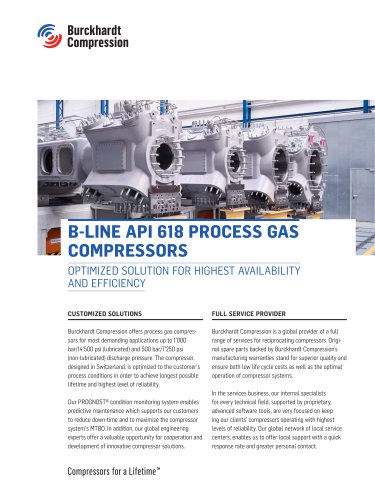

B-Line

2 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Redura(R) Piston Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages