Website:

Burckhardt Compression AG

Website:

Burckhardt Compression AG

Catalog excerpts

(fBurckhardt estCompression INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR Dr. Norbert Feistel Compressors for a Lifetime

Open the catalog to page 1

2 INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR Dr. Norbert Feistel received his degree in Mechani-cal Engineering (Dipl.-Ing.) from the University of Karlsruhe, Germany in 1987. He began his professional career as a design engineer with Mannesmann Demag Foerdertechnik in Offenbach/ Main, Germany. In 1988 N. Feistel joined the R&D Group of Burck-hardt Compression in Winterthur. After approxi-mately two years, in which N. Feistel's activities concentrated mainly on the labyrinth piston com-pressors, his responsibilities are now for the development of...

Open the catalog to page 2

INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR 3 In order to achieve the highest possible voLumetric efficiency during oil-free compression of hydrogen, it is necessary to maximize the performance of dry-running sealing systems. The compression of smatt and medium flow rates to high pressures, as required for fitting gas botttes and for process gas compression in the chemical industry, can be viewed as especiaLLy criticaL aspects. Due to the very smatt piston diameters typicatty invotved in the final stages, the covering of the seating-etement joints...

Open the catalog to page 3

4 INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR CHAPTER 2 Fig. 1 Various styles of piston rings VARIOUS STYLES AND APPLICATIONS OF PISTON RINGS Piston rings for double-acting cylinders with large diameters usu-ally are one-piece rings with a butt or scarf joint. Fig. ia/b In the case of these designs, the joint is not sealed either axially or radially, thus minimizing the risk of failure by fracture even for brittle materials. However, progression in wear is accompanied by a proportional increase in the flow area of the ring joint and a resultant...

Open the catalog to page 4

INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR 5 CHAPTER 3 suction pressure higher than atmospheric pressure. The gas cycle was fed with hydrogen having a dew point > -65 °C. The hydrogen flow rate was measured with a thermal mass flowmeter for potentially explosive atmospheres. Fig. 6 With the bypass concept, a fraction of the gas flow to be measured is routed via a small sensor tube, where it causes a temperature difference between two electric windings (acting as both heat-ers and resistance-temperature detectors) which is proportional to the mass...

Open the catalog to page 5

6 INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR Fig. 5 Fig. 6 Two-stage, crosshead hydrogen compressor for investigating the operational Measurement of hydrogen flow rate by means of a thermal mass flowmeter behavior of dry-running sealing systems for potentially explosive atmospheres 3.2 METHODOLOGY The various piston ring designs also influence the pressure distribution inside the sealing system. In the case of new piston rings of a gastight design, the entire pressure difference is typically sealed by just one or two sealing elements at the ends of...

Open the catalog to page 6

table.main {} tr.row {} td.cell {} div.block {} div.paragraph {} .font0 { font:4.00pt "Arial", sans-serif; } .font1 { font:5.00pt "Arial", sans-serif; } .font2 { font:6.00pt "Arial", sans-serif; } .font3 { font:7.00pt "Arial", sans-serif; } .font4 { font:8.00pt "Arial", sans-serif; } .font5 { font:9.00pt "Arial", sans-serif; } .font6 { font:10.00pt "Arial", sans-serif; } .font7 { font:14.00pt "Arial", sans-serif; } .font8 { font:16.00pt "Arial", sans-serif; } .font9 { font:17.00pt "Arial Black", sans-serif; } .font10 { font:8.00pt "Impact", sans-serif; } .font11 { font:5.00pt "Lucida Sans...

Open the catalog to page 7

8 INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR This highlights the advantage of maintaining the best possible joint sealing also during double-acting compressions of hydrogen, even if the resultant benefits are hardly apparent in the new state of the piston rings. The twin ring proves advantageous here, since its sealing element is designed to wear completely in theory without permitting a direct flow through the joint. CHAPTER 6 TESTS WITH PROGRESSIVE WEAR As notable variations in capacity were established already on new piston rings of various...

Open the catalog to page 8

INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR 9 Fig.10 Dependence of capacity on piston ring design during single-acting compression Fig. 11 Relative capacity vs. time of four piston rings with a scarf joint, conventional twin rings and form-fit coupled twin rings (measurement interval: 300 seconds) "ET c y ci a p a 240 220 200 180 160 140 120 100 80 60 40 20 0 Twin ring A Step cut joint ■ Scarf joint ♦ Two-piece with spring ▼ Two-piece without spring 110 100 90 80 70 60 50 40 30 20 10 0 JWՉ *** ■Y A (1, in y ci a p a Form-fit coupled twin rings...

Open the catalog to page 9

10 INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR The large diffrences in the wear rates of the couplecl twin rings are typical of gastight sealing elements which, in their new state, seal the entire pressure difference with just one or two sealing elements3, 4. The concentration of the dynamic and static pressure components at the two ends of the sealing system results here in a maximum value of as much as 1.76 mm at the last sealing element, a stable, high capacity being ensured by the outstanding wear compensation properties. A distribution of the...

Open the catalog to page 10

INFLUENCE OF PISTON RING DESIGN ON THE CAPACITY OF A DRY-RUNNING HYDROGEN COMPRESSOR 11 Notation pd suction pressure [MPa] discharge pressure [MPa] constant pressure after the last sealing element [MPa] pdyn dynamic pressure difference: Pdyn = pd -ps [MPa] pstat static pressure difference: pstat = ps -pz [MPa] cm average piston velocity [m/s] n speed [min-1] PTFE polytetrafluoroethylene Rfrences 1 Bartmann, L.: Beitrag zur Bestimmung der Leck-verluste im Arbeitszylinder eines Kolben-kompressors Dissertation TH Karlsruhe, 1968 2 Beckmann, W.: Ermittlung von Einflussfaktoren auf das...

Open the catalog to page 11All Burckhardt Compression AG catalogs and technical brochures

-

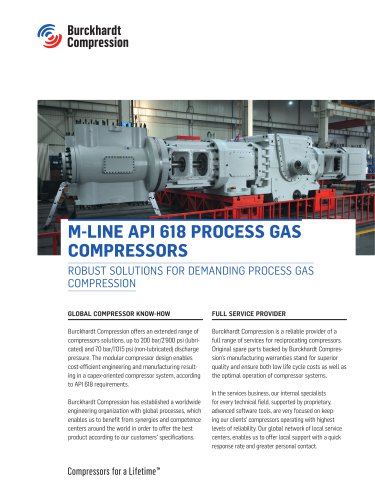

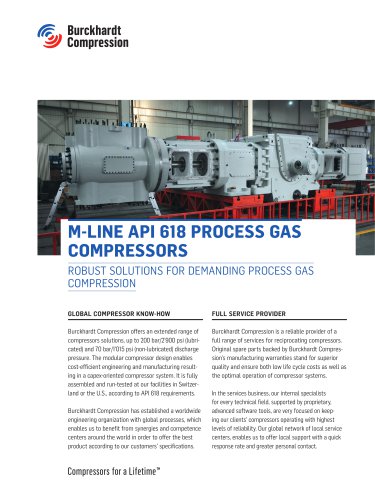

M-Line

2 Pages

-

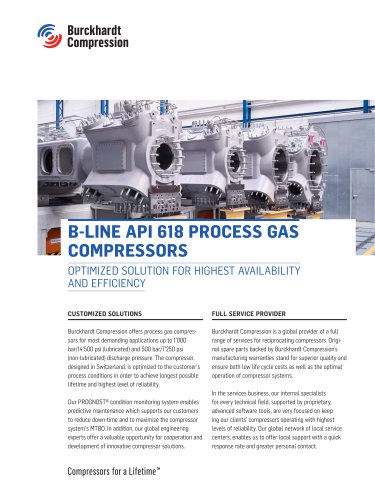

B-Line

2 Pages

-

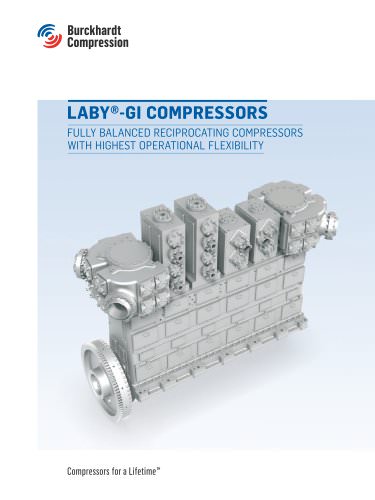

LABY®-GI

24 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Redura(R) Piston Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages