Catalog excerpts

(f Burckhardt éyCompression THE UNIQUE SEALING SYSTEM Peter Ernst Compressors for a Lifetime

Open the catalog to page 1

2 HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM Peter Ernst received his degree as Mechanical Engineer (Dipl.-Ing. HTL) in 1969 from the Engineering Institute (ISZ), Zurich, Switzerland. He then started his professional career as mechanical engineer in the design department for labyrinth piston compressors of Sulzer in Winterthur, Switzerland. He played a leading role in compressor sizing and development. In 1989 he became manager of the engineering department, in 1992 head of the technical department of labyrinth piston compressors and in 2001, with the...

Open the catalog to page 2

HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM 3 For LNG ship transportation, a cryogenic receiving terminal is required at the port of destination. Impressive installations are required for safe and economic storage and handling of LNG and associated boil-off gases created during unloading and storage. Safe and environment-conscious handling of the cargo, prevention of leaks, exposure of materials to cryogenic temperatures and bone-dry gas, as well as rapid temperature changes, are of high concern to the plant and compressor designers. Among the rotating...

Open the catalog to page 3

4 HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM CHAPTER1 CHAPTER2 INTRODUCTION An LNG boil-off compressor has to cope with a variety of basic physical problems for which a product designed to normal standards would be inadequate. Two aspects of special interest include: 1.1 EXPOSURE TO CRYOGENIC TEMPERATURES LNG at barometric pressure boils off at minus 160 °C. This temperature is well below the limit where some of the common engineering materials alter their properties. For example, the loss of ductility of most unalloyed carbon steels within a temperature...

Open the catalog to page 4

HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM 5 Fig. 2 Transitions of impact energies of non alloyed C-steels and Ni-alloyed nodular iron 360 y-p ar o y g er n e ct a p _§ 60 I Ni-Resist D-2M y-p ar o y g er n e ct a p 320 240 160 40 80 20 Ni-Resist D5 0 -200 -100 0 100 Temperature (°C) 0 -200 -100 0 100 200 Temperature (°C) Fig. 3 Cross section view of a double acting labyrinth piston Table 2 Candidate materials for low temperature components. Comparative combined properties. Tensile strength Endurance Young's Thermal Thermalshock Ratio 1: Ratio 2: Thermal...

Open the catalog to page 5

6 HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM Fig. 4 Coefficient of thermal expansion for cast iron and steel in function of % Ni and temprature x n io si n a p x e al rm er e of n ie ici ef o C 20 18 16 / \ 14 / \ 20 12 U / 16 / 10 \ / 8 \ ! 12 \ / 6 \J 8 4 4 2 0 Cast iron and steel \ -1-1-F-1-F-1-1-1 -200 0 200 400 600 Temperature (°C) 0 20 40 60 80 Ni% by weight in cast iron Fig. 5 Icing of first stage cylinder Fig. 6 Laby® for LNG boil-off, two double acting cylinders, two compression stages, closed gastight crankcase, design suction temperature minus...

Open the catalog to page 6

HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM 7 Fig. 7 Fig. 8 Internai labyrinth sealing between double acting cylinder and distance piece Gas-tight sealing of crankshaft between crankcase and environment of crankcase (piston rod seaiing) CHAPTER 3 CHAPTER4 TEMPERATURE AND DEFORMATION OF CRANKCASE Gas temperatures at the first stage inlet valves are so low that energy imparted to the cylinders during gas compression raises their mean temperature to a value still well below that of ambient air. Therefore they do not have cooling jackets. They cool down well...

Open the catalog to page 7

8 HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM Table 3 Maintenance report on a period of 110'000 running hours (1998) CHAPTER5 OTHER LNG TERMINALS The successful performance of the Laby® in this market segment has encouraged other terminais to install new machines of the same kind built to the same principles. Fig. 9 shows a group of three Laby® Compressors for LNG boil-off in a Taiwanese terminal where LNG is received, stored and evaporated for distribution by a pipeline system throughout the island of Taiwan. Fig. 9 The first three identical Laby®...

Open the catalog to page 8

HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM 9 Fig. 11 Suction valve with gas actuated unloading device CHAPTER7 CAPACITY CONTROL There are two main reasons, why compressor regulation is used: The most prevalent one is to adjust the suction flow to match the process demand. The second important reason is to save energy. In contrast to many other compressor types, reciprocating com-pressors offer a large variety of capacity control systems. The correct type of capacity control is determined by many param-eters. Not all types of capacity controls can be used...

Open the catalog to page 9

10 HIGH RELIABILITY OF THE LABY® LNG BOG COMPRESSOR WITH THE UNIQUE SEALING SYSTEM Fig.13 One of two LNG boil-off gas compressors in the design stage and as installed on-site at the BBG Bilbao LNG receiving terminal, Spain CHAPTER 8 PLANT DESIGN In addition to being a compressor designer and manufacturer, Burckhardt Compression also engineers, procures and provides com-missioning of whole systems. The use of their systems is demon-strated in every nut and bolt from suction to discharge side of the compression unit, comprising pulsation equipment, filters, lube oil systems, motor driver, gas...

Open the catalog to page 10

(f Burckhardt éyCompression RECIPROCATING COMPRESSORS LEADING TECHNOLOGY FOR LOWEST LIFE CYCLE COSTS COMPRESSOR COMPONENTS BEST PERFORMANCE AND LONGEST LIFETIME CUSTOMER SUPPORT SERVICE THE FULL RANGE OF SERVICES Laby® Compressors Contactless and oil-free \ Laby®-GI Compressors \ J -I f'f Fully balanced Valves: - Burckhardt Poppet ValveTM - Burckhardt Plate ValveTM - Manley® valve, licensed by Burckhardt Compression Piston rings Guide rings Piston rod packings Burckhardt Valve Service Spare parts logistics Field service Technical support Component repair Engineering services Revamps...

Open the catalog to page 12All Burckhardt Compression AG catalogs and technical brochures

-

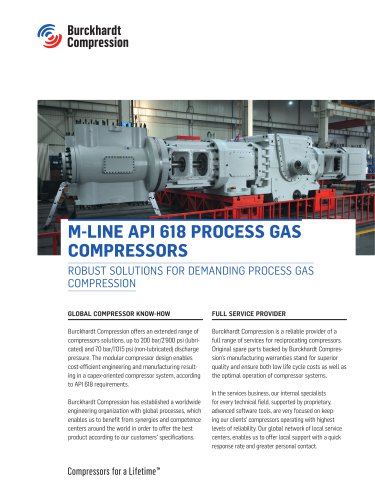

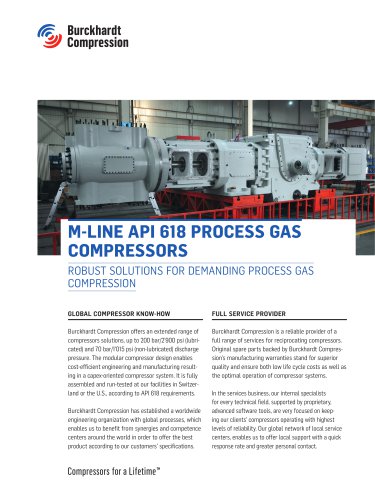

M-Line

2 Pages

-

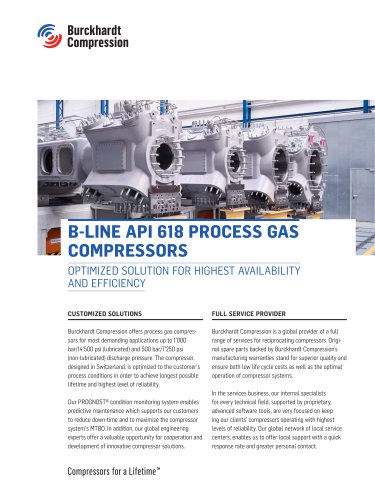

B-Line

2 Pages

-

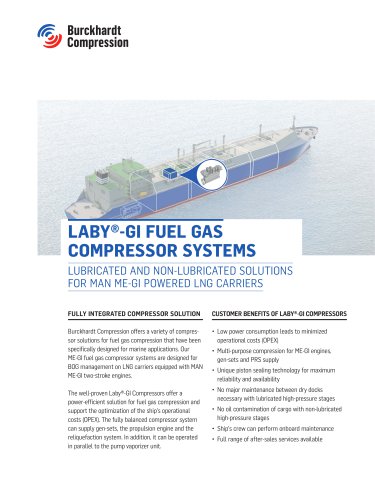

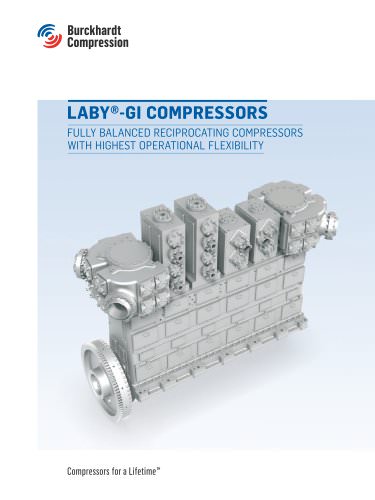

LABY®-GI

24 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Redura(R) Piston Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages