Catalog excerpts

PROVEN TECHNOLOGIES FOR RELIABLE AND EFFICIENT PLANT OPERATION

Open the catalog to page 1

Compressor Solutions for LNG Terminal Applications LNG – PLAYING AN IMPORTANT ROLE IN THE FUTURE ENERGY MARKET CHALLENGING THE INDUSTRY Growing natural gas markets Demand for environmentally friendly natural gas as a fossil fuel will continue to increase over the long term. Replacing the liquid fossil fuels of diesel, gasoline and oil with natural gas would reduce global carbon dioxide emissions by about 30%. Coal and nuclear energy are increasingly substituted by natural gas amid widespread efforts to decarbonize growing economies and to diversify energy supply in many regions of the...

Open the catalog to page 2

Compressor Solutions for LNG Terminal Applications Trend (down/upwards) Import trade movements (no. of dots = quantity color of dots = source)

Open the catalog to page 3

Compressor Solutions for LNG Terminal Applications UNIQUE COMPRESSOR SOLUTIONS FOR A WIDE RANGE OF APPLICATIONS FROM LIQUEFACTION TO REGASIFICATION The LNG process consists of natural gas production, purification and liquefaction, ship loading, transportation and subsequent off-loading, storage, and regasification and, ultimately, injection into a gas distribution grid or power plant. Burckhardt Compression offers unique, economical s olutions for compressing and reliquefying boil-off gas from liquid gases. Liquefaction terminals Natural gas is generally received by pipeline. Before it is...

Open the catalog to page 4

Compressor Solutions for LNG Terminal Applications DEMANDING OPERATING CONDITIONS MAIN EQUIPMENT AS A KEY SUCCESS FACTOR Low temperatures Special materials are required to handle boil-off gas (BOG) at ultra low temperatures down to –160°C. Oil-free compression At such low temperatures, oil-free compression is required. Besides the non-conformity of oil with these temperatures, conventional sealing systems show low lifetime behavior under bone-dry cryogenic working conditions. Icing of cylinders at temperatures down to minus 160°C Varying gas conditions Compression of different volumes of...

Open the catalog to page 5

Compressor Solutions for LNG Terminal Applications MOST ECONOMIC BOG HANDLING SOLUTIONS 75 YEARS OF EXPERIENCE IN OIL-FREE COMPRESSION OF CRYOGENIC GASES Efficient operation –– No loss of valuable product due to gas tight design –– No purge gas required –– No pre-heating/pre-cooling of gas required –– Insensitive to fluctuating suction conditions (pressure, temperature, mass flow and gas composition) Safety standards –– No leakage of process gas to environment –– Proven design for highest safety standards –– High quality of in-house developed components for longest meantime between overhaul...

Open the catalog to page 6

Compressor Solutions for LNG Terminal Applications Lowest life cycle costs –– Contactless labyrinth sealing system –– No friction, no wear on cylinders, pistons and piston rod –– Longest MTBO, low maintenance and operating costs 3rd year 3rd year 2nd year 1st year Maintenance costs and spare parts Initial price Laby® Laby® Compressor system for BOG application HIGHLY FLEXIBLE OPERATION – Suction Temperatures from +40 °C / +100 °F down to –160 °C / –260 °F Discharge temperature second stage 0 / 30 Discharge temperature rst stage Suction temperature rst stage

Open the catalog to page 7

Compressor Solutions for LNG Terminal Applications HIGHLY RELIABLE MINIMUM SEND-OUT PIPELINE COMPRESSION With a comprehensive range of proven compression technologies, Burckhardt Compression offers unique and reliable solutions for minimum send-out (MSO) pipeline compression. Depending on customer requirements, we develop specific compressor solutions in close cooperation with our customers. Typical applications –– BOG to pipeline (MSO/peak shaving) –– Recondenser to pipeline (MSO/peak shaving) Laby®-GI Compressor BOG to pipeline or either/or Laby® Compressor for BOG Handling MSO pipeline...

Open the catalog to page 8

Compressor Solutions for LNG Terminal Applications Compression solutions from A SINGLE SOURCE –– High quality of in-house developed components for longest MTBO –– Proven reliability and availability with hundreds of references –– BOG handling and pipeline compression from one manufacturer and service provider Laby®-GI Compressor system for MSO application

Open the catalog to page 9

10 Compressor Solutions for LNG Terminal Applications Complete Portfolio of Reciprocating Compressor Technologies COMPRESSOR SOLUTIONS FOR LNG APPLICATIONS – ONSHORE AND OFFSHORE Laby® Compressor Laby®-GI Compressor bara / psia PERFORMANCE Range Discharge pressure Laby®-GI Compressor Laby® Compressor

Open the catalog to page 10

Compressor Solutions for LNG Terminal Applications Three Laby® Compressor systems for BOG application at a Chinese LNG terminal

Open the catalog to page 11

12 Compressor Solutions for LNG Terminal Applications WORLDWIDE INSTALLATIONS OF BC COMPRESSORS AT TERMINALS

Open the catalog to page 12

Compressor Solutions for LNG Terminal Applications 13 Canaport LNG Terminal CAnada Fujian LNG Terminal China Barcelona LNG Terminal Spain Isle of Grain LNG Terminal United Kingdom

Open the catalog to page 13

LNG tank at Bilbao LNG terminal

Open the catalog to page 15

16 Compressor Solutions for LNG Terminal Applications Burckhardt Compression THE RECIPROCATING COMPRESSOR COMPANY WITH thorough IN-HOUSE EXPERIENCE …

Open the catalog to page 16

Compressor Solutions for LNG Terminal Applications 17 … ENSURING COMPREHENSIVE SUPPORT BOTH FOR EPC CONTRACTORS AND PLANT OPERATORS Research & Development Tribology incl. test beds Finite element analysis Mechatronics Labyrinth sealing technology Material research ve Compressor Design Instationary fluid dynamics Pre-sales support, incl. detailed documentation Engineering analysis Feasibility studies Selection and sizing Pulsation and vibration studies 3D CAD Compressor valves Material selection according to application requirements serviceS Engineering services Spare parts logistics Revamps...

Open the catalog to page 17

18 Compressor Solutions for LNG Terminal Applications Wherever, Whenever You Need It Burckhardt valve service Fast valve service with extensive guarantee Spare parts logistics OEM guarantee and best life cycle costs Field service benefit from our skilled recip experts and our offshore experience Technical support Professional support from our well trained and experienced specialists Component repair Save money and get “as new” guarantee Engineering services Sophisticated in-house sizing and analysis tools – Analysis of valve condition – Tracking of valve history – OEM valve engineering –...

Open the catalog to page 18All Burckhardt Compression AG catalogs and technical brochures

-

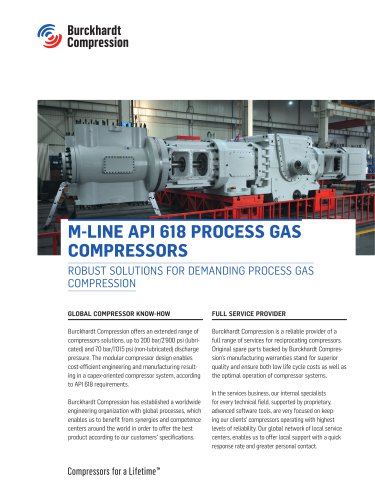

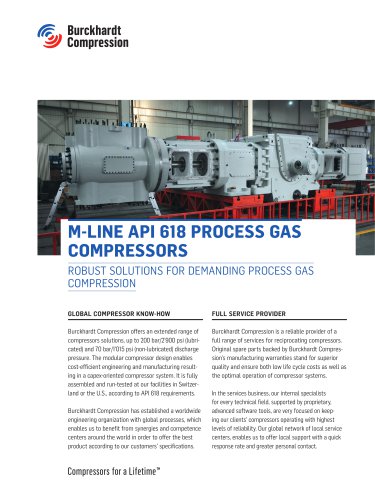

M-Line

2 Pages

-

B-Line

2 Pages

-

LABY®-GI

24 Pages

-

LABY

24 Pages

-

COMPACT PACKAGE

12 Pages

-

Redura(R) Rod Sealing Systems

16 Pages

-

Redura(R) Piston Sealing Systems

16 Pages

-

Hyper Compressors

24 Pages

-

Reciprocating compressors

8 Pages

-

Laby-GI Compressors

24 Pages

-

Laby Compressors

24 Pages