Catalog excerpts

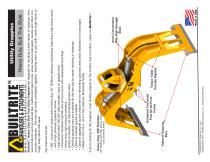

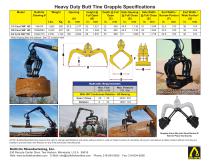

Torque Tubes Provide Rigidity P/N HD-BTG GRAPPLE 3-7-2012 © September 2015 - Builtrite Manufacturing, Inc. - All Rights Reserved. Optional Gripping Bars Hardened, Oversized Pins On All Pivot Points (20” Bearing with High Torque, Heavy Duty Hydraulic Motor) Heavy Duty, 360° Rotation Arms Constructed With High Strength Steel If you’re looking for the toughest, most durable grapple on the market, look no further...make it a BuiltriteTM. • 360°, continuous rotation with a heavy duty, 20” (508mm) slewing ring bearing, featuring a high torque motor and a high pressure hydraulic swivel. • High tensile steel (100,000 yield strength) used on grapple arms. • Oversized, hardened cylinder and arm pivot pins with replaceable bushings. • Heavy duty, high pressure cylinders. • Easily accessible, yet well protected grease zerks. • Optional gripping bars are available for the tine tips for easier handling of materials. • Optional cylinder guards available. • Optional aggregate bucket attachment for rehandling purposes (see photo illustration on back page). • Made in the U.S.A., at our Two Harbors, Minnesota facility. BuiltriteTM, Heavy Duty Butt Tine Utility Grapples are designed for handling a wide variety of materials, from wood products such as railroad ties, matting and logs to pipe, jersey barriers (parapets), beams and other construction materials. The tine tips come completely together, allowing them to pick both small single items to large, bulky items with ease. Heavy Duty, Butt Tine

Open the catalog to page 1

Grapple with 360° •fflorianoanfl Bucke Optional * Wide Gripping Bars are optional - See “G” in above table. Grapple Arms Slip Into Sand Bucket & Hold In Place Via Gravity NOTE: Builtrite Manufacturing reserves the right to change specifications and prices without notice in order to follow its policy of constantly striving to manufacture a better product without incurring any liability to provide these new features on any units previously manufactured. Builtrite Manufacturing, Inc. 530 Recycle Center Drive, Two Harbors, Minnesota, U.S.A. 55616 Web: www.builtritehandlers.com E-Mail:...

Open the catalog to page 2All Builtrite Mfg catalogs and technical brochures

-

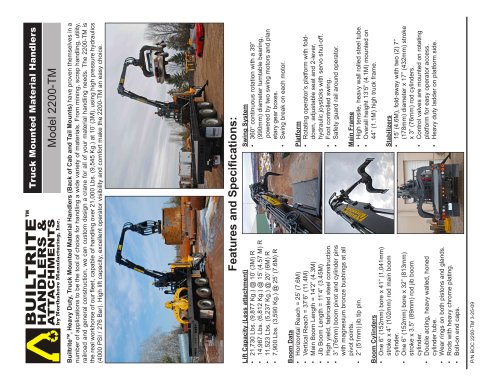

2300-SE

2 Pages

-

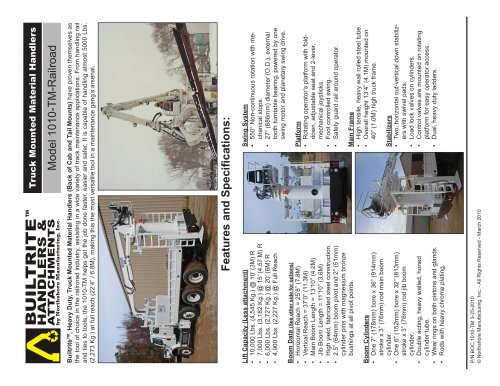

Model 1010-SE

2 Pages

-

Auto Dismantler

2 Pages

-

Bale Clamp Waste Grapple

2 Pages

-

Builtrite All Products Catalog

16 Pages

-

Magnet Rotator

2 Pages

-

Trash Tamping Grapple

1 Pages

-

2/3 Tine Scrap Grapple

2 Pages