Catalog excerpts

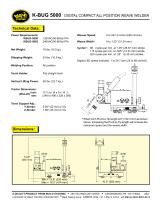

Digital Compact All position weave Welder Technical Data: Power Requirements: KBUG-5000 120VAC/50-60Hz/1Ph KBUG-5002 240VAC/50-60Hz/1Ph Net Weight: Torch Holder: Fits straight torch Vertical Lifting Power: Cycles*: 68 cycles per min. at 1.05" (26.67 mm) stroke 115 cycles per min. at .525" (13.34 mm) stroke 200 cycles per min. at .25" (6.35 mm) stroke Welding Position: Weave Width*: Shipping Weight: Weaver Speed: Digital LED speed indicator: 1 to 34.7 ipm (25 to 88 cm/min) Torch Support Adj.: Y-Stroke: Z-Stroke: Tractor Dimensions: inch: 13 5/8 to 16 x 9 x 10 1/4 (WxLxH) mm: (346 to 406 x 228 x 260) * When torch Pivot-to-Tip length is 6" (152.4 mm) as shown above. Increasing the Pivot-to-Tip length will increase the maximum speed and the weave width. DIGITAL, COMPACT, ALL POSITION PENDULUM WEAVE WELDER A track guided travel carriage with oscillation for welding in all positions Increases welding production Improves weld quality Reduces operator fatigue A QUALITY PRODUCT FROM BUG-O SYSTEMS Bug-O Systems A DIVISION OF WELD TOOLING CORPORATION © Weld Tooling Corp. Automated Cutting and Welding Systems. 412-331-1776 www.bugo.com Bug-O Systems is guided by honesty, integrity and ethics in service to our customers and in all we do.

Open the catalog to page 1

The K-BUG 5000 is a compact portable welding unit with an integrated pendulum weaver for all position welding. It mounts to BUG-O Systems Aluminum Rigid Rail and attaches to work surface via magnets or vacuum system in any position. It will perform continuous welding at a constant travel speed producing high quality uniform welds in a fraction of the time required for manual welding. Regulated travel speed without starting and stopping the welding process will eliminate excessive weld deposition and help reduce defects. Precise weld weaving with programmable dwells will improve weld...

Open the catalog to page 2

The K-BUG 5000 is a compact portable welding unit with an integrated pendulum weaver for all position welding. It mounts to BUG-O Systems Aluminum Rigid Rail and attaches to work surface via magnets or vacuum system in any position. It will perform continuous welding at a constant travel speed producing high quality uniform welds in a fraction of the time required for manual welding. Regulated travel speed without starting and stopping the welding process will eliminate excessive weld deposition and help reduce defects. Precise weld weaving with programmable dwells will improve weld...

Open the catalog to page 3

Digital Compact All position weave Welder Technical Data: Power Requirements: KBUG-5000 120VAC/50-60Hz/1Ph KBUG-5002 240VAC/50-60Hz/1Ph Net Weight: Torch Holder: Fits straight torch Vertical Lifting Power: Cycles*: 68 cycles per min. at 1.05" (26.67 mm) stroke 115 cycles per min. at .525" (13.34 mm) stroke 200 cycles per min. at .25" (6.35 mm) stroke Welding Position: Weave Width*: Shipping Weight: Weaver Speed: Digital LED speed indicator: 1 to 34.7 ipm (25 to 88 cm/min) Torch Support Adj.: Y-Stroke: Z-Stroke: Tractor Dimensions: inch: 13 5/8 to 16 x 9 x 10 1/4 (WxLxH) mm: (346 to 406 x...

Open the catalog to page 4All BUG-O SYSTEMS catalogs and technical brochures

-

UNI-BUGS

4 Pages

-

AUTOMATIC ARC GOUGING SYSTEM

4 Pages

-

FIXTURING EQUIPMENT

4 Pages

-

PIPER-PLUS PIPE WELDING SYSTEM

12 Pages

-

STIFFENER WELDERS

4 Pages

-

SUPPORTS AND ACCESSORIES

4 Pages

-

RAILS & ATTACHMENTS

8 Pages

-

BEVELERS

2 Pages

-

GO-FER® IV

6 Pages

-

AUTOMATIC HEIGHT CONTROL

2 Pages

-

Zipper Welder

4 Pages

-

K-BUG 5050/K-BUG 6050

4 Pages

-

Arc Gouger

4 Pages

-

FixturesEquipment

4 Pages

-

Tank Fabrication

8 Pages

-

DC Speed Weaving Kit

2 Pages

-

Supports & Accessories

4 Pages

-

Programmable Shape Machine

4 Pages

-

DC-IV Tractor

2 Pages

-

Trac-Bug

2 Pages

-

Uni-bug III

4 Pages

-

Unibug II

4 Pages

-

Speed Weaver II

4 Pages

-

Beam Bug III

4 Pages

-

Universal Bug-o-matic

4 Pages

-

Piper Plus Pipe Welding System

12 Pages

-

Con-o

2 Pages

-

Cir-o

2 Pages

-

Hob-o

2 Pages

-

General Catalogue

24 Pages

-

Modular Drive System

16 Pages

-

Weld Backings

2 Pages

-

Portable Plate Beveler

2 Pages

-

Hob-o Blind Area Kit

2 Pages

-

Torches

2 Pages

-

Go-fer III

6 Pages

-

Programmable Gantry

4 Pages

-

Auto Height Control

2 Pages

-

TAR-GIT

2 Pages

-

Pitbull Beveler

2 Pages

-

Stiffener Welder

4 Pages

-

DC General Welding Kit

2 Pages

-

All Position Overlay System

2 Pages

-

Heavy Duty Sub-arc Tractor

2 Pages

-

Pipe-Bug

4 Pages

Archived catalogs

-

Sprinkler Brochure

6 Pages

-

Weld Backings

2 Pages