Website:

Bühler Group

Website:

Bühler Group

Group: Bühler

Catalog excerpts

Drum sieve

Open the catalog to page 1

Efcient precleaning. Reliable removal of coarse impurities. Application This drum sieve, which is patented in numerous countries, can be applied in many different ways for precleaning materials. It is successfully used in the reception of granular, mealy, and oury bulk materials in grain mills, bulk storage systems, and other plants in the food processing and feed manufacturing industries. The drum sieve separates coarse impurities such as pieces of straw, bag tapes, paper, pieces of wood, and corn (maize) leaves and cobs, etc. This protects downstream processing and conveying equipment...

Open the catalog to page 2

High throughputs. MKZM drum sieves. MKZM drum sieves. In service in an English flour mill. In service in a Chinese flour mill. High throughputs coarse impurities Proven, sturdy design Easy maintenance Corn (maize) Wheat Barley Rice Oats Soybea

Open the catalog to page 3

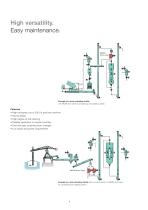

High versatility. Easy maintenance. MKZM drum sieve Example of a truck unloading facility with MKZM drum sieve for precleaning and weighing system. Features • High throughput up to 500 t/h grain per machine • Sturdy design • High degree of self-cleaning • Reliable separation of coarse impurities • Fast and easy screening drum changes • Low space and power requirements MKZM drum sieve Example of a ship unloading facility with conveying system to MKZM drum sieve for precleaning and weighing system.

Open the catalog to page 4

Minimized space and power requirements. High throughputs. Throughput range according to hole size, in t/h Examples: Material Corn (maize) Cocoa beans Finely ground grain up to 0.44 t/m3 Coarsely ground grain 0.55–0.60 t/m3 1 Material inlet 2 Throughs (cleaned stock) 3 Coarse impurities 4 Aspiration connection 5 Inlet channel 6 Inlet cylinder 7 Discharge cylinder with guide screw 8 Curved bottom 9 Scraper brush 10 Gearmotor 11 Service cover Technical data Model Screening drum Ø Length 778 Approx. weights in kg net gross seapacked H*: Space required for removing the screening drum

Open the catalog to page 5All Bühler Group catalogs and technical brochures

-

DRPR

2 Pages

-

DRPN

6 Pages

-

DRCA

2 Pages

-

DRWD

2 Pages

-

DRWE

2 Pages

-

MTSD

4 Pages

-

SpeedmixTM Batch Mixer

8 Pages

-

Ophthalmic optics

32 Pages

-

MacroMedia

8 Pages

-

Trias

8 Pages

-

SORTEX® A

12 Pages

-

SORTEX S UltraVision Brochure

12 Pages

-

Oil Cleaner 2000 / 4000

2 Pages

-

Ecoline

12 Pages

-

Carat

20 Pages

-

Grain Solution Brochure

16 Pages

-

Nuts and Dried Fruit Solution

16 Pages

-

SORTEX E PolyVision for Plastic

12 Pages

-

SORTEX A for Grain

12 Pages

-

SORTEX B for Grain

12 Pages

-

SORTEX B Range

12 Pages

-

SORTEX A Range

12 Pages

-

SORTEX F BioVision for Nuts

12 Pages

-

SD Three-Roll Mills

12 Pages

-

Cenomic

8 Pages

-

MicroMedia

8 Pages

-

PML 2

8 Pages

-

MicroMedia+

8 Pages

-

Trinomic

8 Pages

-

Precision optics

44 Pages

-

Ophthalmic ptics

36 Pages

-

Plansifter Arenit MPAV.

8 Pages

-

Whitener TopWhite™ BSPB

6 Pages

-

MGEL Elevator

4 Pages

-

RGEL

4 Pages

-

Automatic Flowbalancer MZAH

4 Pages

-

Chain Conveyor MNKA

4 Pages

-

Chain conveyor RFKG

2 Pages

-

UltraPoly rice polisher

8 Pages

-

Whitener TopWhite? BSPB

6 Pages

-

MWPF-A/ MWPF-E/ MWPF-W

4 Pages

-

Granex silo scale. MSDT.

8 Pages

-

Bagging Scale

4 Pages

-

Check Scale MSDP

2 Pages

-

MSDL

4 Pages

-

Automatic Hopper Scale MSDL

2 Pages

-

Automatic Hopper Scale MSDM

8 Pages

-

Impact Dehuller DOSB

4 Pages

-

Impact Dehuller DGBB

4 Pages

-

Cascade Aspirator OLSA

4 Pages

-

Pellet Mill RPWR

4 Pages

-

Fluid Bed OLHA

4 Pages

-

Cracking Mill OLCB

4 Pages

-

Flaking Mill OLFB

8 Pages

-

Flaking Mill DOQB

4 Pages

-

Scourer MHXT

4 Pages

-

Horizontal Scourer MHXS

4 Pages

-

Airlocks MPSH, MPSJ, MPSK

8 Pages

-

Plug Diverter MAYK

2 Pages

-

Truck unloading screen MKTA

2 Pages

-

Evolution

20 Pages

-

Pinch Bag Sealing Unit

2 Pages

-

Bag Pusher MWTQ

6 Pages

-

Antares Plus MDDR / MDDT

4 Pages

-

Air-Recyling Aspirator MVSQ

4 Pages

-

AeroDry Impingement Oven

4 Pages

-

Air-recycling aspirator MVSR

4 Pages

-

AeroToastTM

4 Pages

-

Twin plansifter Azurit MPAU

4 Pages

-

Twin-Screw Feeder MWSP

4 Pages

-

Twin-Screw Feeder MWSQ

4 Pages

-

Bühler UltraLine

6 Pages

-

Universal Grist Mill Maltomat

12 Pages

-

ValueCard Automation

2 Pages

-

Vane-type discharger DMBV

2 Pages

-

Vibro-Discharger MFVH

2 Pages

-

Vibro-Discharger MFVK

2 Pages

-

Volumetric Feed Gate MZDE

4 Pages

-

Long-Goods Pasta Cooler TDKD

16 Pages

-

Flow Balancer MZAL

4 Pages

-

Dampener Turbolizer MOZL

4 Pages

-

Conditioner HYMIX Plus

2 Pages

-

AeroExpander

4 Pages

-

Aspiration Channel MVSG/H

4 Pages

-

Flaking Roller Mill DOZC

4 Pages

-

Hammer Mill Granulex? DFZP

2 Pages

-

MWBC

4 Pages

-

BuhlEx_S

2 Pages

-

MGXD

4 Pages

-

MSDP

2 Pages

-

Centrifugal_Sieve

2 Pages

-

Pastelec

2 Pages

-

MWSK

2 Pages

-

K Series

6 Pages

-

Drum Magnet DFRT

2 Pages

-

BuhlEx S.

2 Pages

-

Cyclone Separator MGXE/MGXG

4 Pages

-

Check Scale MSDP

2 Pages

-

Centex™

8 Pages

-

C-line® Short Goods Dryer

6 Pages

-

Belt Feeder MWSK

2 Pages

-

Bag Conveyor MWTK

4 Pages

Archived catalogs

-

SORTEX A range.

12 Pages

-

Automatic Hopper Scale MSDM

2 Pages