Catalog excerpts

Bucher Unipektin AG Murzlenstrasse 80 CH-8166 Niederweningen Tel. +41 44 857 23 00 Fax +41 44 857 23 41 info@bucherunipektin.com Bucher Filtrox Systems AG Moosmühlestrasse 8 CH-9000 St. Gallen Tel. +41 71 272 91 11 Fax +41 71 278 11 82 info@bucherfiltrox.com Bucher Alimentech Ltd. 13b Gabador Place, Mt. Wellington P O Box 14-258 Panmure Auckland, New Zealand Tel. +64 9 573 1333 Fax +64 9 573 1334 info@bucherunipektin.com Bucher Unipektin AG Oddzial w Polsce Al. Niepodlegtosci 107/109-39 PL-02-626 Warszawa Tel. +48 22 844 85 29 Fax +48 22 844 85 29 info@bucherunipektin.com Bucher Unipektin AG Moskau Rep. Office Olympiysky prospect 16 RU-129090 Moskau Tel. +7 495 974 12 68 Fax +7 495 626 55 27 info@bucherunipektin.com Beijing Bucher Unipektin Equipment Co. Ltd. Room 1909 Twin Towers Upper East Side, No.2 Dongsihuan Beilu Chaoyang District CN-Beijing100016 Tel. +86 10 5978 26 08 Fax +86 10 5978 26 09 info@bucherunipektin.com Innovative Ion-Exchange and Adsorber Systems Bucher Industries AG Murzlenstrasse 80 CH-8166 Niederweningen Tel. +41 43 815 80 80 Fax +41 43 815 80 81 info@bucherind.com www.bucherind.com Bucher Specials Machinery for the wine and beverages production, beer filtration, environmental technology, trading company for tractors and specialised agricultural machinery as well as control systems for automation technology. Bucher Municipal Compact and truck-mounted sweepers. Bucher Hydraulics Custom made, hydraulic drive and control technology for vehicles and machines. Kuhn Group Farm machinery for hay and silage, feed preparation, soil preparation, seeding and fertilisation technology and plant care. Emhart Glass Glass forming and inspection machines, systems and controls devices for the container glass industry. From fruit to juice…

Open the catalog to page 1

Innovative Ion-Exchange and Adsorber Systems Bucher Unipektin is the market leader in the development, manufacture and installation of technically sophisticated individual machines and consolidated systems for fruit juice production. Bucher Unipektin has an international reputation for the depth of staff knowledge and for the high quality of the machinery we construct. All machines exported are built to comply with local regulations including CE for Europe, UL for USA. Bucher Unipektin – Always There When You Need Us! These are not empty words. Going the extra mile in the interest of our...

Open the catalog to page 2

Area of Expertise Bucher Unipektin has the expertise for the development, design, and manufacture of ion-exchange and adsorption polymer based processes for the fruit juice and other food industries. Other areas of expertise are specialist water treatment applications such as deionisation, nitrate removal and iron removal. Bucher Unipektin is independent of resin manufacturers, allowing the optimal resin to be chosen for each application. We will contract research processes specific to individual customer needs. Process Application

Open the catalog to page 3

Adsorption Process In an adsorption process the product is contacted with an adsorbent polymer resin in a fixed bed. The polymer adsorbs the component to be removed by physical interactions (London and van der Waals forces). No components from the resin are released into the product. When the polymer’s capacity to adsorb is exhausted the product is displaced from the column. The polymer is regenerated and prepared for the next process cycle. Adsorption Principle Ion-Exchange Process In an ion-exchange process the product is contacted with ion-exchange resins. Mineral and organic ions in the...

Open the catalog to page 4

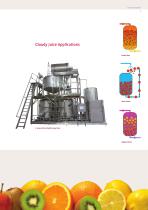

Bucher Unipektin Bucher Foodtech 3 Systems for Clear Products Clarified products are treated in fixed beds. Resin remains in the vessel during the complete processing and resin regeneration cycle. Traces of haze are removed during a fluidising step. System for Clear Juice Systems for Cloudy Products Bucher Unipektin has developed a unique process for treatment of nonfiltered juices containing up to one percent of pulp. Any particles retained in the resin bed during processing are removed by transferring the resin through a unique washing process prior to regeneration. This provides a long...

Open the catalog to page 5

The cloudy juice systems are mainly used for upgrading citrus juices and by-products, e.g. peel extracts. The following processes have been successfully developed and commercialised: • Debittering of orange juice: limonin reduction to below taste threshold (< 5 ppm) • Bitterness reduction of grapefruit (reduction of naringin) • Debittering and astringency reduction for flavour enhancement of citrus peel extracts and whole fruit comminutes. • Debittering of WESOS • Acid reduction or ratio adjustment • Reduction of browning in lemon juice • Debittering of tropical juices, such as Mango Feed...

Open the catalog to page 6

Bucher Unipektin Bucher Foodtech 5 Cloudy Juice Applications Production Resin Wash 2-Vessel Citrus Debittering Plant

Open the catalog to page 7

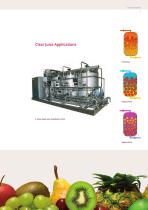

Clear Juice Applications The clear juice systems are used for a broad range of applications, typically for upgrading the sensory properties and haze stability of juices or the manufacture of valuable products from waste material. The following processes have been successfully developed and commercialised: • Stabilisation to prevent haze formation of apple, pear and grape juice • Colour reduction and standardisation of apple and pear juice • Patulin reduction of apple and pear juice • Hesperidin reduction to prevent haze formation of lemon juice • Reduction of browning in lemon juice •...

Open the catalog to page 8

Bucher Unipektin Bucher Foodtech 7 Clear Juice Applications 3-Vessel Apple Juice Stabilisation Plant

Open the catalog to page 9

Process Development Laboratory Bucher Unipektin operates a well equipped laboratory. In-depth research and verification of techniques and materials is completed to a high standard at bench-scale. Results are used to design processes to suit customer requirements. Additional analytical tools are available nearby at government and university research facilities. Research work is also undertaken with customers on a contractual and confidential basis. Pilot Plants Once a process is established in the laboratory further testing, process proving and development can be carried out at the...

Open the catalog to page 10All Bucher Unipektin AG catalogs and technical brochures

-

Bucher HPX 6007

2 Pages

-

Bucher HPX 7507

2 Pages

-

Bucher HPX 12007

2 Pages

-

Transport Screw Conveyor

2 Pages

-

Collecting Screw Conveyor

2 Pages

-

Adsorber

2 Pages

-

Ion Exchanger

2 Pages

-

Ultra Star XL

2 Pages

-

ContiStar

2 Pages

-

MiniStar

2 Pages

-

LabStar

2 Pages

-

CIP

2 Pages

-

Sludge dewatering technology

8 Pages

-

Innovative filtration

12 Pages

-

Beverage technology-juice

15 Pages

-

HPS 7507

2 Pages

-

HPS 12007

2 Pages

-

HPS 3007

2 Pages

-

Sludge Dewatering

8 Pages

-

Bucher HPX 7507

2 Pages

-

Bucher HPS 6007

2 Pages

-

Bucher HPX 3007

2 Pages

-

DryCab

2 Pages

-

DryBand

2 Pages

-

UltraStar XL

2 Pages

-

Mash Heater

2 Pages

-

KVS mill

2 Pages

-

CM Mill

2 Pages

-

C 25 Mill

2 Pages

-

Overview Reception Line

2 Pages

Archived catalogs

-

Evaporator

2 Pages

-

BUCHER Unipektin Evaporator

2 Pages