Catalog excerpts

BRUGG-STAMANT ® Safety Pipe Systems description proval l type ap Genera 07 Z-38.4-2

Open the catalog to page 1

BRUGG-STAMANT® Safety Pipe 5.101 BRUGG-STAMANT® Safety Piping 5.102 General type approval 5.103 Technical project description leak detector 5.104 Technical project description materials specification 5.201 BRUGG-STAMANT® construction elements 5.400 Leak detection BRUGG-STAMANT® Safety Piping 5.410 Leak detection on the vacuum principle 5.450 Leak detection on the positive pressure principle 5.470 Leak detection on the positive pressure principle 5.601 Selection of construction elements from our standard range 5.801 Details for underground works...

Open the catalog to page 2

BRUGG-STAMANT® Safety Pipe Systems description Monitorable BRUGG-STAMANT® Safety Piping BRUGG-STAMANT® Safety Piping is a prefabricated double-walled piping system delivered in construction elements, in the dimensions DN 15/32 to DN 800/900, which is particularly suitable for the transport of flammable and non-flammable water hazardous substances. The installation and laying of the construction elements is done by specialist firms certified acc. to §19 l WHG, TRbF 50 who can prove their qualifications in process and welding techniques. The annular gap between the inner and secondary...

Open the catalog to page 3

BRUGG-STAMANT® Safety Pipe General type approval Z-38.4-207 The construction design of BRUGG-STAMANT® Safety Piping with leak monitoring is manufactured and used in projects according to the description in the general type approval and according to the pressure device regulations 97/23/EG, as well as according to the construction regulations of the TRbF 50. The system is subject to the requirements of 11.GSGV, § 19 g WHG , §7 BetrSichV (Operating Safety Ordinance) and the requirements of the various German federal states under the VAwS. Principles of testing and evaluation used in the leak...

Open the catalog to page 4

BRUGG-STAMANT® Safety Pipe Leak detector (Safety piping and leak monitoring) approved for the transport of water-hazardous (flammable and non-flammable) media acc. to VbF i.Vm. of the 11. GSGV, WHG, VAwS Safety piping as a double-walled steel piping construction with surveillance space as part of a leak detection system. Type: BRUGG-STAMANT® safety piping Leak monitoring (acc. to TRbF 502) Positive pressure leak detector Vacuum leak detector Manufacturer BRUGG Rohrsysteme GmbH Installation / laying by authorized specialist firms certified acc. to § 19 l WHG and TRbF...

Open the catalog to page 5

BRUGG-STAMANT® Safety Pipe Technical project description materials specification Inner pipe Dimensions seamless and welded pipes acc. to EN 10220 Technical conditions of delivery acc. to TRbF 50 or EN 10216-2, 10217-1, 10217-2, 10208-2 Acceptance test certificate acc. to DIN EN 10204 – “3.1.“ Outer pipe Dimensions seamless and welded pipes acc. to EN 10220 Technical conditions of delivery acc. to TRbF 50 or EN 10216-2, 10217-1, 10217-2, 10208-2 With external PE corrosion-proofing jacket acc. to DIN 30670 or DIN 30671. Acceptance test certificate acc. to DIN EN 10204 – “3.1.“ IP elbow Pipe...

Open the catalog to page 6

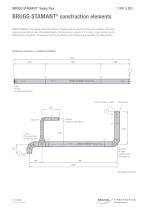

BRUGG-STAMANT® Safety Pipe BRUGG-STAMANT® construction elements BRUGG-STAMANT® safety piping construction elements already include all necessary fittings such as elbows, T-branches, reducing sleeves and end seals. The standard length of the construction elements is 12.0 metres. Longer elements can be delivered after consultation. The maximum length of the elements is only limited by the availability of suitable transport. Construction elements in a completed installation 12100 3100 BRUGG-STAMANT® Safety Pipe Flange End seal Connection leak detector number stamp 0 = upside LA end seal...

Open the catalog to page 7

BRUGG-STAMANT® Safety Pipe Leak monitoring BRUGG-STAMANT® safety piping is permanently monitored using pneumatic leak detection equipment/ leak detectors. These regulate the monitoring pressure in the surveillance space and register any changes of pressure which may occur. The surveillance space is filled with the leak detection medium (an inert gas) and prevents uncontrolled spillages of the transport medium when leaks occur. The surveillance space must be so constructed that the functioning and operative security of the leak detection system (the leak detector) is assured at all times...

Open the catalog to page 8

BRUGG-STAMANT® Safety Pipe Leak detection on the vacuum principle The leak detector on the vacuum principle is suitable and approved for monitoring BRUGG-STAMANT® Safety Piping for the transport of: – flammable water-hazardous substances with an ignition point > 55 °C only in the Ex version – non-flammable water-hazardous substances. Principles of functioning The vacuum pump installed in the leak detector creates a partial vacuum inside the surveillance space. By monitoring this partial vacuum, leaks in the walls of the piping are automatically detected. In the event of a drop in the...

Open the catalog to page 9

BRUGG-STAMANT® Safety Pipe Leak detection on the positive pressure principle The leak detector on the positive pressure principle is suitable and approved for monitoring BRUGG-STAMANT® Safety Piping for the transport of: – flammable water-hazardous substances – non-flammable water-hazardous substances. Principles of functioning The operating pressure necessary in the surveillance space of the BRUGG-STAMANT® Safety Piping is regulated by the actual pressure in the operating pipe (inner transport pipe) and is – generated by topping up, regulated by pressure changes, from a stationary nitrogen...

Open the catalog to page 10

BRUGG-STAMANT® Safety Pipe Leak detection – special design high pressure BRUGG-STAMANT® Safety Pipe is a product custom-made for every single project. Consequently also the associated leak detection systems are planned individually and in an economic way for any application. By use of the vacuum leak detection system a working pressure up to 25 bars with and without explosion protection can be realized. A positive pressure leak detection system anables pipe systems with feed pressure up to 300 bars to be monitored. These systems are equipped with high-pressure fittings and safety components...

Open the catalog to page 11All Brugg Pipesystems catalogs and technical brochures

-

Spiramant Flyer

2 Pages

-

Brugg Seminars

20 Pages

-

Flexwell-LPG Piping

2 Pages

-

Flexwell Safety pipe technology

32 Pages

-

Biogas technology Flyer

24 Pages

-

LMS 320 Monitoring device

2 Pages

-

LMS 120 Monitoring device

2 Pages

-

AdBlue Flyer

2 Pages

-

Eigerflex Catalogue

25 Pages

-

Premant Catalogue

70 Pages

-

Casaflex catalogue

32 Pages

-

Flexwell Catalogue

33 Pages

-

Urbanflex

2 Pages

-

CALPEX Leaflet

8 Pages

-

CALPEX district heating pipe

56 Pages

-

CALPEX PUR-KING

6 Pages

-

COOLMANT

22 Pages

-

COOLFLEX

27 Pages

-

Datasheet Secon-X

2 Pages

-

NIROFLEX Flyer

6 Pages

-

Leak Monitoring Systems

8 Pages

-

FLEXWELL-LNG Small Scale

4 Pages

-

BRUGG-STAMANT Safety Pipe

2 Pages

-

SECON-X Brochure

20 Pages

-

FLEXWELL-LPG

16 Pages

-

Hotelflyer

6 Pages

-

Cooling Flyer

4 Pages

-

Biogastechnik Flyer

13 Pages

-

FSR Flyer

6 Pages

-

PREMANT Brochure

6 Pages

-

CASAFLEX brochure

8 Pages

-

FLEXWELL FHK

6 Pages

-

COOLMANT/COOLFLEX Flyer

8 Pages

-

FSR Brochure

32 Pages

-

SPIRAFLEX Brochure

6 Pages

-

Datasheet PETREX

2 Pages

-

EIGERFLEX Flyer

4 Pages

-

CRYOFLEX

6 Pages