Catalog excerpts

Biogas technology The effective heating system for biogas-fermenters BRUGG/ PIPESYSTEMS _____Flexible solutions

Open the catalog to page 1

Fermenter equipment with NIROFLEX® corrugated piping The helically corrugated NIROFLEX® piping is the ideal solution through its simple and nonweld installation. Installation - fast and convenient laying - simple pipe securing - non-weld connectors including through-connection through the tank wall Other advantages: - excellent corrosion resistance - highly exible and self-compensating - far higher heat transfer than with conventional piping For installation instructions and technical data: see Worksheets Biogas technology BGT. CALPEX® heat-insulated pipe CALPEX® can be laid direct into the...

Open the catalog to page 2

Connection outside the fermenter In this variant, in order to set up the connection with the corrugated pipe using the ameless GRAPA graphite connector system outside the fermenter, the corrugated pipe is bent through a small bending radius and led through a pipe sleeve which passes through the fermenter wall. This does away with the need for a joint in the fermenter. ()* + In addition to the corrugated pipe CNW 60/66, the system package also includes the GRAPA connector system, the necessary wall through-connections including seals and the special brackets for securing the piping to the...

Open the catalog to page 3

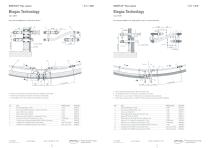

NIROFLEX® Pipe system Biogas Technology End connector GRAPA-S incl. wall duct dla. 89 mm • Pleas note: the support type F (outlet) has to be installed 70 mm higher. • Gasket insert needs to be seated on the wall duct in full length. • For installation of the end connector see installation instruction. No. Type Material grade Article No. 2_End connector GRAPA-S DN 50 incl. wall duct dia. 89 mm_1.4301_72803704 5 Gasket insert type A WD 35-94, core drilling dia. 1E0 mm 1.4301 72803782 6 Fixing set incl. dowel BS10 (brehole dia. 12 mm) 1.4301/Nylon 72803796 8_Installation tool for GRAPA-S end...

Open the catalog to page 4

NIROFLEX® Pipe system NIROFLEX® Pipe system Installation instructions Fermenter Installation instructions Fermenter Installing the pipe work CNW 60/66, DN 50 with connector and seal Installing the pipe work CNW 60/66, DN 50 with connector and seal Installation of the NIROFLEX pipe work in a fermenter Measuring and marking the position of the pipe supports The height of the supports on the fermenter wall is determined by the position of the drill holes. The pipe work must lie axially to the core hole. Measure the height of all supports using a laser measuring device and drill the holes for...

Open the catalog to page 5

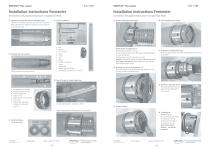

NIROFLEX® Pipe system NIROFLEX® Pipe system Installation instructions Fermenter Installation instructions Fermenter Leading out the pipe work CNW 60/66, DN 50 with connector and seal Leading out the pipe work CNW 60/66, DN 50 with connector and seal 10 Position of the bending support relative to the core hole Important! The exact measurements must be observed to ensure that the wall duct is centrally aligned. 16 Fixing the pipe to the supports The corrugated pipe must now be xed to the further supports by means of stirrup clamps. 13 Bending the pipe out of the tank At least 4.5 m of loose...

Open the catalog to page 6

NIROFLEX® Pipe system NIROFLEX® Pipe system Installation instructions Fermenter Installation instructions Fermenter End connector with graphite sealing ring for corrugated pipe DN 50 End connector with graphite sealing ring for corrugated pipe DN 50 22 Fitting the connector with wall duct and gasket insert Attention! The wall duct is 250 mm long. If the wall of the tank is thinner than 250 mm, shorten the wall duct to at least the thickness of the tank wall. 27 Position of the groove when sawing 30 Put the sealing ring (3) in place Minimum tank wall + insulation 23 Packaged unit with...

Open the catalog to page 7

NIROFLEX® Pipe system NIROFLEX® Pipe system Installation instructions Fermenter Installation instructions Fermenter End connector with graphite sealing ring for corrugated pipe DN 50 End connector with graphite sealing ring for corrugated pipe DN 50 34 Front view The sealing chamber, comprising the pressure ring (2), the supporting ring (4) and the sealing ring (3) is now precisely aligned 37 Fitting the installation anges Attention: Insert the split rear ange in the groove (see illustration) Important! Grease the screws! 41 Fit the lashing strap again at the position shown! 45 The pipe end...

Open the catalog to page 8

Fermenterbeheizung Biogaspark Könnern Fermenter heater Biogas Park Könnern Fermenter heater Biogas Park Könnern Fermenterbeheizung Biogaspark Könnern Anwendungsbeispiele Case Study Case Study Ort Location D-06420 Könnern Könnern WELtec Biopower GmbH Biopower GmbH Ausgangslage Job Einsatz der BRUGG Fermenterbeheizung für To install the BRUGG heating system for fermenters den zurzeit weltgrößten Biogas currently the in the Biogas Park in Könnern, Park in largest in the world, so as to Biogasprozesses. Könnern zur Optimierung des optimize the biogas production process. Herausforderung...

Open the catalog to page 9

Fermenterbeheizung Fermenter heater in Neuerkerode Anwendungsbeispiele Biogas Plant Neuerkerode Fermenter heater Biogas Plant Neuerkerode Fermenterbeheizung in Neuerkerode Anwendungsbeispiele Case Study Case Study Ausgangslage Job Installation von Wellrohren aus korrosionsbeTo install corrosion-proof stainless steel corrugated ständigem Edelstahl zur Wärmeübertragung, pipes for heat exchange without welding work on site, without separable connectors inside ohne örtliche Schweißarbeiten, ohne lösbare the fermenter. Verbindungen im Fermenter. Challenge Herausforderung To install the fermenter...

Open the catalog to page 10

Fermenterbeheizung BGA Plant Schnega Fermenter heater BiogasSchnega Fermenter heater BiogasSchnega Fermenterbeheizung BGA Plant Schnega Anwendungsbeispiele Case Study Case Study Ausgangslage Job Eine bestehende BiogasanlagePE pipes as heating An existing biogas plant with mit PE-Rohren als Fermenterheizung. Aufgrund von Diffu- with system for the fermenter. Due to problems diffusion from the piping, a better wurde hier sionsproblemen der Heizungsrohre solution was needed. eine bessere Lösung gesucht. Produkt Product Austausch Fermenterheizung PE-Rohr Replacement of a heating system for the...

Open the catalog to page 11All Brugg Pipesystems catalogs and technical brochures

-

BRUGG-STAMANT Safety Pipe

14 Pages

-

Spiramant Flyer

2 Pages

-

Brugg Seminars

20 Pages

-

Flexwell-LPG Piping

2 Pages

-

Flexwell Safety pipe technology

32 Pages

-

Biogas technology Flyer

24 Pages

-

LMS 320 Monitoring device

2 Pages

-

LMS 120 Monitoring device

2 Pages

-

AdBlue Flyer

2 Pages

-

Eigerflex Catalogue

25 Pages

-

Premant Catalogue

70 Pages

-

Casaflex catalogue

32 Pages

-

Flexwell Catalogue

33 Pages

-

Urbanflex

2 Pages

-

CALPEX Leaflet

8 Pages

-

CALPEX district heating pipe

56 Pages

-

CALPEX PUR-KING

6 Pages

-

COOLMANT

22 Pages

-

COOLFLEX

27 Pages

-

Datasheet Secon-X

2 Pages

-

NIROFLEX Flyer

6 Pages

-

Leak Monitoring Systems

8 Pages

-

FLEXWELL-LNG Small Scale

4 Pages

-

BRUGG-STAMANT Safety Pipe

2 Pages

-

SECON-X Brochure

20 Pages

-

FLEXWELL-LPG

16 Pages

-

Hotelflyer

6 Pages

-

Cooling Flyer

4 Pages

-

FSR Flyer

6 Pages

-

PREMANT Brochure

6 Pages

-

CASAFLEX brochure

8 Pages

-

FLEXWELL FHK

6 Pages

-

COOLMANT/COOLFLEX Flyer

8 Pages

-

FSR Brochure

32 Pages

-

SPIRAFLEX Brochure

6 Pages

-

Datasheet PETREX

2 Pages

-

EIGERFLEX Flyer

4 Pages

-

CRYOFLEX

6 Pages