Catalog excerpts

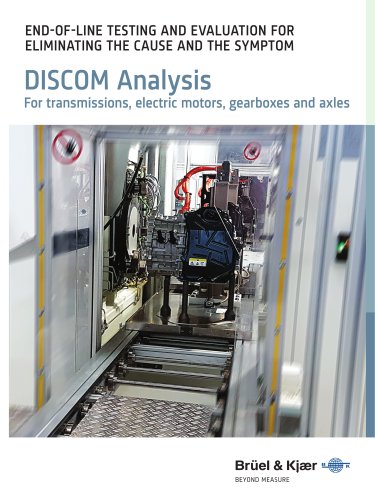

END-OF-LINE TESTING AND EVALUATION FOR ELIMINATING THE CAUSE AND THE SYMPTOM DISCOM Analysis For transmissions, electric motors, gearboxes and axles

Open the catalog to page 1

SIMPLIFYING THE PROCESS Vehicle noise is the sum of its parts, which are many: including power plant, input shafts, axles and all the gears in between. To help you bring the best possible powertrain to the market, DISCOM Analysis uses rotationally synchronous order analysis and averaging to go beyond registering a bad transmission or motor; the system identifies the source of the problem and points to its cause. Once identified, the failure can be traced back to its root cause and mitigated or eliminated. Eliminating problems before they happen improves cost-effectiveness, saves time and...

Open the catalog to page 2

be measured then begins the Know your production test sequence. Each test cycle The results of every test run, consists of a number of steps from every test stand in the that generate specific results, for production line, are collected in a large results database. This • 3rd gear speed ramp up database is the anchor point • Torque ramp phase 1 production analysis tool, that • Differential test highlights current production problems, offers trend analysis, helps refine limits, and closes the sequence, or even repeated or loop of continuously enhanced omitted. In each test step all...

Open the catalog to page 3

UNIQUE APPROACH TO DATA PROCESSING AND ANALYSIS TasAlyser has numerous display capabilities for evaluation and results TasAlyser software is the data analysis part of the system. It controls data acquisition and processes the signals. Using rotationally synchronous averaging, this software computes one analysis channel for each rotor and each sensor. Signal components of the synchronous shaft are enhanced, while other noise components are attenuated. This provides the acoustical properties and any defects of for each shaft. DISCOM Analysis can process data for 20+ shafts, simultaneously,...

Open the catalog to page 4

PROCESSING CHANNELS Channels are labelled based on their function and type, for example, “Input Shaft Sync”. The Mix channel is processed without rotational averaging, so it contains the contributions of all noise sources. Sync channel

Open the catalog to page 5

www.bksv.com/production-testing DISCOM For the past 20 years, DISCOM has developed and distributed systems for acoustical quality analysis used in end-of-line testing, and these systems are highly respected and used worldwide by companies in and around the automotive industry. Brüel & Kjær acquired DISCOM on July 26, 2016. This acquisition enables Brüel & Kjær to better support its customers by expanding its production quality testing capabilities to end-of-line analysis solutions. Brüel & Kjær also provides networks for DISCOM to better support customers and additional resources to...

Open the catalog to page 6All Bruel and Kjaer catalogs and technical brochures

-

Data Analysis Software

6 Pages

-

B&K 2245 Sound Level Meter

8 Pages

-

HBK 2255 Sound Level Meter

10 Pages

-

Artificial Mastoid Type 4930

6 Pages

-

Power Amplifier Type 2718

2 Pages

-

DISCOM Mobile

6 Pages

-

DISCOM NVH Analysis Systems

4 Pages

-

TEDS Microphones

8 Pages

-

LDS V8

4 Pages

-

LDS Comet USB

4 Pages

-

LDS Laser USB

16 Pages

-

2690-A

16 Pages

-

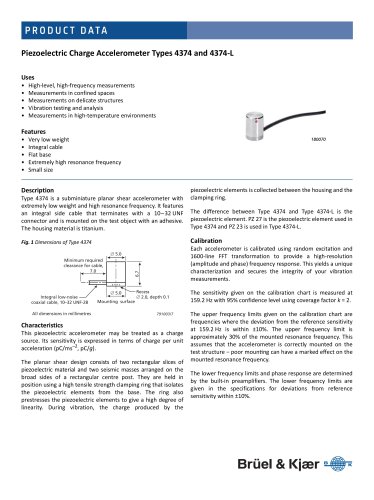

4374

2 Pages

-

4326-A-001

8 Pages

-

4152

4 Pages

-

4191

2 Pages

-

2719

2 Pages

-

LDS V8900

4 Pages

-

BKS 10

8 Pages

-

1704-A-001

4 Pages

-

4939

2 Pages

-

4138

4 Pages

-

4101-B and 4965-B

4 Pages

-

Sonoscout NVH Recorder

8 Pages

-

LDS Power Amplifiers

8 Pages

-

Type 2720

2 Pages

-

Type 2721

2 Pages

-

TYPE 3668

4 Pages

-

3656-A

4 Pages

-

TYPE 2270-S

28 Pages

-

LDS V994

2 Pages

-

TYPE 8702

16 Pages

-

BZ-7848-A

40 Pages

-

TYPE 9718-A:bp0317

12 Pages

-

TYPE 4720:bp1974

12 Pages

-

TYPE 4824:bp1936

4 Pages

-

SOUND LEVEL METER:bp 2025

28 Pages

-

Transducers and conditioning

188 Pages

-

Noise Sentinel Overview

3 Pages

-

Analyzer Catalogue

39 Pages

-

Noise Logger Type 3659

1 Pages

-

Sound level meters

17 Pages