Website:

Brooks Instrument

Website:

Brooks Instrument

Group: ITW

Catalog excerpts

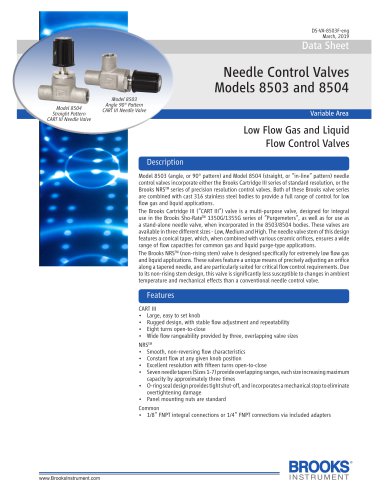

Data Sheet Needle Control Valves Models 8503 and 8504 Model 8504 Straight Pattern CART III Needle Valve Model 8503 Angle 90° Pattern CART III Needle Valve Variable Area Low Flow Gas and Liquid Flow Control Valves Description Model 8503 (angle, or 90° pattern) and Model 8504 (straight, or “in-line” pattern) needle control valves incorporate either the Brooks Cartridge III series of standard resolution, or the Brooks NRSTM series of precision resolution control valves. Both of these Brooks valve series are combined with cast 316 stainless steel bodies to provide a full range of control for low flow gas and liquid applications. The Brooks Cartridge III (“CART III”) valve is a multi-purpose valve, designed for integral use in the Brooks Sho-RateTM 1350G/1355G series of “Purgemeters”, as well as for use as a stand-alone needle valve, when incorporated in the 8503/8504 bodies. These valves are available in three different sizes - Low, Medium and High. The needle valve stem of this design features a conical taper, which, when combined with various ceramic orifices, ensures a wide range of flow capacities for common gas and liquid purge-type applications. The Brooks NRSTM (non-rising stem) valve is designed specifically for extremely low flow gas and liquid applications. These valves feature a unique means of precisely adjusting an orifice along a tapered needle, and are particularly suited for critical flow control requirements. Due to its non-rising stem design, this valve is significantly less susceptible to changes in ambient temperature and mechanical effects than a conventional needle control valve. Features CART III • Large, easy to set knob • Rugged design, with stable flow adjustment and repeatability • Eight turns open-to-close • Wide flow rangeability provided by three, overlapping valve sizes NRSTM • Smooth, non-reversing flow characteristics • Constant flow at any given knob position • Excellent resolution with fifteen turns open-to-close • Seven needle tapers (Sizes 1-7) provide overlapping ranges, each size increasing maximum capacity by approximately three times • O-ring seal design provides tight shut-off, and incorporates a mechanical stop to eliminate overtightening damage • Panel mounting nuts are standard Common • 1/8” FNPT integral connections or 1/4” FNPT

Open the catalog to page 1

Product Specifications Capacities and Pressure Drops Standard: 1/8“ Female NPT - integral 1/4” female NPT Materials of Construction Stainless Steel Model Body & Stem Orifice Valve Needle Plunger (NRS only) O-rings 316 stainless steel NRS Size 1-3: Stainless steel and Teflon®; NRS Sizes 4-6: Stainless Steel; CART III all sizes: PEEK® (ceramic) 316 stainless steel Stainless steel Viton® fluoroelastomers; Buna-N Capacity Table NRS Needle Taper Units 1 2 3 4 5 6 7 CART III Size Low Medium High *U.S. Customary Units capacities measured with 10 PSIG supply and atmospheric exhaust....

Open the catalog to page 2

Cartidge Valve Sizing GAS - United States Customary Units The correct cartridge valve can be determined for any gas by using one of the formulas below: GAS - Standard International Units The correct cartridge valve can be determined for any gas by using one of the formulas below: 1. Subcritical Flow Formula (when downstream pressure, P2, is greater than the critical pressure PC, or P1< 2P2) 1. Subcritical Flow Formula (when downstream pressure, P2, is greater than the critical pressure PC, or P1< 2P2) 2. Critical Flow Formula (when downstream pressure, P2, is less than the critical pressure...

Open the catalog to page 3

Model Code Code Description I. Base Model Number Option Description Angle pattern In-line pattern III. Needle and Orifice Size NRS Size 1 NRS Size 2 NRS Size 3 NRS Size 4 NRS Size 5 NRS Size 6 NRS Size 7 CART III Low CART III Medium CART III High Buna N Viton® fluoroelastomers V. Inlet/Outlet Connections, Size & Type 1/8” NPT (integral) 1/4” NPT (adapters supplied) Sample Standard Model Code I II III 8504F 2 1 Service and Support Brooks is committed to assuring all of our customers receive the ideal flow solution for their application, along with outstanding service and support to back it...

Open the catalog to page 4All Brooks Instrument catalogs and technical brochures

-

Quantim® Series

9 Pages

-

SolidSense II® Series

12 Pages

-

Sho-Rate Series

9 Pages

-

947N

4 Pages

-

0260 Series

4 Pages

-

0250 Series

8 Pages

-

LR-056

4 Pages

-

VDM300

4 Pages

-

XacTorr® Series

8 Pages

-

CMC Series

4 Pages

-

PC100 Series

4 Pages

-

SLA7840

4 Pages

-

SLA10/20/40 Series

12 Pages

-

5866RT

4 Pages

-

122 Series Pressure Gauges

4 Pages

-

8600 Series

2 Pages

-

MT3809 Series

24 Pages

-

MT3750 Series

13 Pages

-

FC Series

8 Pages

-

GT1600 Series

11 Pages

-

9861 Series

5 Pages

-

5850EMH Series

5 Pages

-

5850EM Series

7 Pages

-

5850E Series

8 Pages

-

GF80 Series

10 Pages

-

GF100 Series

12 Pages

-

GF100 Series EtherCAT®

9 Pages

-

GF125 Series

12 Pages

-

5700 Series

4 Pages

-

4800 Series

10 Pages

-

SLAMf Series

12 Pages

-

GF40 Series

12 Pages

-

SLA5800 Series

11 Pages