Website:

Bronmetal

Website:

Bronmetal

Group: Lontana Group

Catalog excerpts

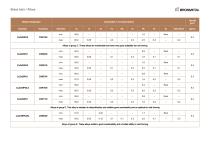

Brass bars / Alloys Alloys COPPER – ZINC – LEAD ALLOYS Material Designation Symbolic Composition in % (mass fraction) Elemento total others Alloys of group A. These alloys exhibit excellent machinability but an aptitude to cold forming very limited min. Alloys of group B. These allors exhibir a good machinability and an aptitude to cold forming min.

Open the catalog to page 1

Brass bars / Alloys Material Designation Symbolic Composition in % (mass fraction) Elemento total others Alloys of group C. These alloys are machinable and have very good suitability dor col forming min. Alloys of group D. This alloy is resistant to dezincification and exhibits good machinabiliy and an aptitude to cold forming min. CuZn36Pb2As

Open the catalog to page 2

Brass bars / Alloys Material Designation Symbolic Composition in % (mass fraction) total others Los productos fabricados con estas aleaciones no son aptos para el mecanizado a altas velocidades. Por tanto no se fabrican barras de Diameter o distancia entre caras inferior a 12 mm. Estas aleaciones se suprimirán de esta norma antes del 1 de enero de 2000. COPPER – ZINC ALLOYS COMPLEX Material Designation Symbolic Composition in % (mass fraction) total others

Open the catalog to page 3

Brass bars / Alloys Material Designation Symbolic Composition in % (mass fraction) total others

Open the catalog to page 4All Bronmetal catalogs and technical brochures

-

BRASS SHEETS

4 Pages

-

COPPER TAPE

2 Pages

-

BRASS BARS /

4 Pages

-

Chapa

1 Pages

-

FLEXICOPPER

4 Pages

-

CuNi2SiCr

2 Pages

-

BRASS TUBES

1 Pages

-

ELECTRICAL SECTOR

56 Pages

-

SECTOR INDUSTRIAL

80 Pages

-

BRONZE SHEETS

1 Pages

-

Copper Tubes

4 Pages

-

COPPER PROFILES

54 Pages

-

COPPER WIRE

1 Pages

-

EN 60228 - Bare Copper Cable

2 Pages

-

FLAT COPPER BAR

2 Pages