Catalog excerpts

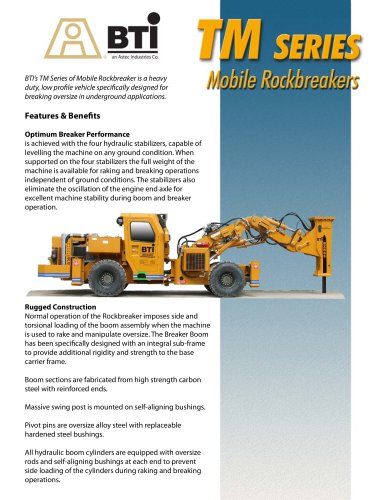

Rockbreaker System FEATURES & BENEFITS Turntable design with 330 degree / constant torque rotation allows for maximum power and performance over the swing range of boom and provides for safe positioning for Sealed turntable slew ring and drive gear design provides for extended service life. Excavator style boom design provided for added strength and increased depth of reach. Massive boom cross sections with reinforced pivot joints provide excellent durability against fatigue. Aluminum bronze bushings and oversized pivot pins are designed for extended service life in high - shock load applications. Joystick Control System complete with anti-lunge control, and anti-blank fire Auto-lube System (boom and breaker) hydraulic or pneumatic Model Turntable & Boom only Complete system * Complete system from smallest to largest with appropriate electric hydraulic power pack. Model Overall Height Working Length Base Hydraulic Breaker Operating Weight: lb (kg) Model Breaker Model Range MRHT ROCKBREAKER SYSTEM BREAKER TECHNOLOGY 1

Open the catalog to page 1

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS STATIONARY TURNTABLE HYDRAULIC BREAKER SYSTEM FOR MINING & QUARRY APPLICATIONS APPLICATIONS JOYSTICK CONTROLS Secondary breaking of oversize material at gyratories, crushers, and grizzlies. CONSTRUCTION CAB A typical system consists of the following main assemblies: HYDRAULIC POWER PACK • Boom Assembly • Hydraulic Breaker • BreakerTool • Joystick Controls • Control Cable • Electric Hydraulic Power Pack • Grease System GREASE - SYSTEM (Optional) MODEL CONFIGURATION BOOM MODEL SERIES I BOOM LENGTH BREAKER MODEL ______... BREAKER...

Open the catalog to page 2

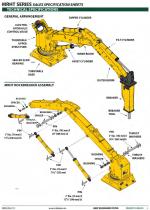

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS GENERAL ARRANGEMENT DIPPER CYLINDER ELECTROHYDRAULIC CONTROL VALVE TILT CYLINDER UPPER STRUCTURE SEALED SLEW BEARING HOIST CYLINDER TURNTABLE BASE OUTER BOOM MRHT ROCKBREAKER ASSEMBLY BUSHING SPACER BUSHING Cr~//SPACE~ R----.._ ~ ~ THRUST~ .~ASHERS , MRHT ROCKBREAKER SYSTEM BREAKER TECH NOLOGY

Open the catalog to page 3

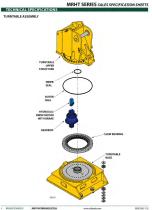

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS TURNTABLE ASSEMBLY TURNTABLE UPPER INNER SEAL HYDRAUliC/. ' DRIVE MOTOR WITH BRAKE GEARBOX/ ~SLEW BEARING BREAKER TECHNOLOGY MRHT ROCKBREAKER SYSTEM

Open the catalog to page 4

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS BREAKER MOUNTING ASSEMBLY TOP MOUNT SIDE MOUNT ..--------- BREAKER TOOL CYLINDER ASSEMBLY TUBE ASSEMBLY TUBE SUPPORT &CLAMP HEAD GLAND Cylinder: Qty of 3 Stroke: 48112'' (1 232 mm) Cylinder Bore: 6" (152 mm) dia. Rod Diameter: 3.5" (89 mm) dia. MRHT ROCKBREAKER SYSTEM BREAKER TECH NOLOGY

Open the catalog to page 5

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS MRHT SERIES CYLINDER, PIN, AND TURNTABLE SPECIFICATIONS CYLINDER SPECIFICATIONS- BORE DIA.I ROD DIA.I STROKE: in (mm) MODELS PIN DIAMETER SPECIFICATIONS- in (mm) INNER HOIST CYLINDER DIPPER CYLINDER TILT CYLINDER FOOTPRINT MOUNTING SPECIFICATIONS BASE SIZE BASE AREA ANCHOR BOLT QTY-SIZE 8 -1 1h " (38 mm) * Limited Rotation Stops can be provided on request MRHT SERIES ROCKBREAKER SYSTEM AND HYDRAULIC BREAKER MATCH UP MATCHING BOOM TO BREAKER MODELS BREAKER TECH NOLOGY MRHT ROCKBREAKER SYSTEM

Open the catalog to page 6

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS PAYLOAD LIFT CAPACITY: MRHT ROCKBREAKER SYSTEM BREAKER TECHNOLOGY 7

Open the catalog to page 7

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS BX I BXR SERIES HYDRAULIC BREAKER SPECIFICATIONS MODELBX20 OPERATING SPECIFICATIONS Energy Class Operating Weight Flow Rate Operating Pressure Tool Diameter Hydraulic Hose Size OPTIONS & ACCESSORIES Remote Grease Connection Remote Air Breather Connect Manual Anti-Blank Blow Selector Manual Two Speed Control Selector Severe Duty Wear Kit OPERATING SPECIFICATIONS Energy Class Operating Weight Tool Diameter Operating Pressure Hydraulic Hose Size 0 OPTIONS & ACCESSORIES Remote Grease Connection Remote Air Breather Connect Manual...

Open the catalog to page 8

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS BX I BXR SERIES HYDRAULIC BREAKER SPECIFICATIONS MODELBX40 OPERATING SPECIFICATIONS OPTIONS & ACCESSORIES Energy Class Remote Grease Connection Operating Weight Remote Air Breather Connect Tool Diameter Manual Anti-Blank Blow Selector Severe Duty Wear Kit Flow Rate Operating Pressure Hydraulic Hose Size OPERATING SPECIFICATIONS OPTIONS & ACCESSORIES Energy Class Remote Grease Connection Operating Weight Remote Air Breather Connect Tool Diameter Anti-Blank Blow Hydraulic Two Speed Control Severe Duty Wear Kit Flow Rate Operating...

Open the catalog to page 9

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS BX I BXR SERIES HYDRAULIC BREAKER SPECIFICATIONS MODELBXR65 OPERATING SPECIFICATIONS OPTIONS & ACCESSORIES Energy Class Remote Grease Connection Operating Weight Remote Air Breather Connect Tool Diameter Anti-Blank Blow Hydraulic Two Speed Control Flow Rate Severe Duty Wear Kit Operating Pressure Hydraulic Hose Size OPERATING SPECIFICATIONS OPTIONS & ACCESSORIES Energy Class Remote Grease Connection Operating Weight Remote Air Breather Connect Tool Diameter Anti-Blank Blow Hydraulic Two Speed Control Flow Rate Severe Duty Wear...

Open the catalog to page 10

MRHT SERIES SALES SPECIFICATION SHEETS TECHNICAL SPECIFICATIONS BX HYDRAULIC BREAKER STRUCTURE & DESIGN FEATURES & BENEFITS • High Strength alloy plate steel construction with abrasion resistant plating allows continuous duty in harsh environment. • Noise dampening material through the breaker eliminates metal-to-metal contact. • Top and bottom isolators absorb recoil energy. Narrow nose design allows improved visibility and minimal over-breaking in trenching applications. Cryogenically enhanced, heat-treated alloy pistons and precise tolerances provide high breaker efficiencies, while...

Open the catalog to page 11

MRHT SERIES SALES SPECIFICATION SHEETS MRHT APPLICATIONS GYRATORY MAXIMUM BREAKER COVERAGE VERTICAL BREAKER COVERAGE The gyratory crusher is the mainstay of medium to large duty crushing plants. Typically, material is brought to the crusher by large haulage trucks and dumped into a rock box. The gyratory crusher is located at the bottom of the rock box. Material is crushed between the eccentrically mounted rotating crushing cone and the fixed, tapered crushing throat. The rockbreaker system is typically installed in line with the spider that supports the cone. This provides superior...

Open the catalog to page 12All Breaker Technology catalogs and technical brochures

-

QS Series Quarry Scalers

3 Pages

-

ALBT Series ANFO Loaders

2 Pages

-

VZ series Hydraulic Breakers

2 Pages

-

TB-XC SERIES BOXED BREAKERS

2 Pages

-

BTI's Full Line brochure

6 Pages

-

TTX Rockbreaker Systems

50 Pages

-

MRXT Rockbreaker Systems

44 Pages

-

MRX Rockbreaker Systems

8 Pages

-

MRH Rockbreaker Systems

50 Pages

-

RMS18 - Hammer Scaler

12 Pages

-

EXC Mechanical Pulverizers

1 Pages

-

MS Series

2 Pages

-

SH hydraulic Shear - Eagle 2

1 Pages

Archived catalogs

-

TB series Hydraulic Breakers

2 Pages

-

MCP series Hydraulic pulverizers

2 Pages

-

HS series Hydraulic shears

2 Pages