Catalog excerpts

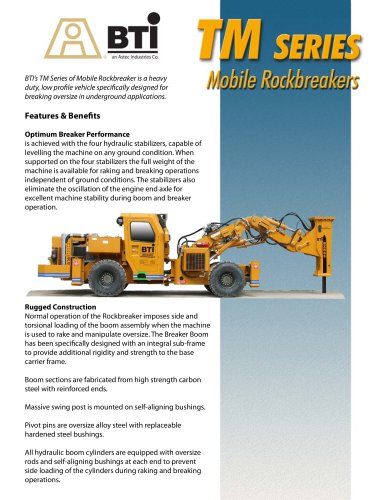

BTI’s TM Series of Mobile Rockbreaker is a heavy duty, low profile vehicle specifically designed for breaking oversize in underground applications. Features & Benefits Optimum Breaker Performance is achieved with the four hydraulic stabilizers, capable of levelling the machine on any ground condition. When supported on the four stabilizers the full weight of the machine is available for raking and breaking operations independent of ground conditions. The stabilizers also eliminate the oscillation of the engine end axle for excellent machine stability during boom and breaker operation. Rugged Construction Normal operation of the Rockbreaker imposes side and torsional loading of the boom assembly when the machine is used to rake and manipulate oversize. The Breaker Boom has been specifically designed with an integral sub-frame to provide additional rigidity and strength to the base carrier frame. Boom sections are fabricated from high strength carbon steel with reinforced ends. Massive swing post is mounted on self-aligning bushings. Pivot pins are oversize alloy steel with replaceable hardened steel bushings. All hydraulic boom cylinders are equipped with oversize rods and self-aligning bushings at each end to prevent side loading of the cylinders during raking and breaking operations.

Open the catalog to page 1

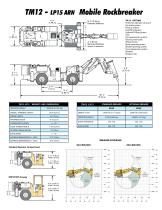

TM 12 OPTIONS Protective operator structure Air intake system Exhaust system Fuel filling System Hydraulic Filling System Tires Fire suppression systems Electric power pack Wheel chocks Boom greasing system Breaker greasing system Dust suppression system Breakers Breaker tools 6’ (1.83 m) 6’ (1.83 m) Retracted Stablizers shown in phantom TM12 -LP15 WEIGHTS AND DIMENSIONS OPERATING WEIGHT OVERALL TRAMMING LENGTH TRAMMING HEIGHT CARRIER ARTICULATION INSIDE TURNING RADIUS BOOM SWING STANDARD BREAKER OPTIONAL BREAKER OPERATING WEIGHT OVERALL WIDTH OUTSIDE TURNING RADIUS ENERGY CLASS MAXIMUM...

Open the catalog to page 2

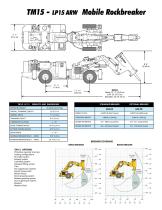

OPERATING WEIGHT STANDARD BREAKER OPTIONAL BREAKER OPERATING WEIGHT OVERALL TRAMMING LENGTH OVERALL WIDTH TRAMMING HEIGHT ENERGY CLASS CARRIER ARTICULATION INSIDE TURNING RADIUS OUTSIDE TURNING RADIUS BOOM SWING MAXIMUM BREAKER REACH - BXR50 MAXIMUM BREAKER REACH - BXR65 BREAKER COVERAGE BXR50 BREAKER Protective operator structure Seating configurations Air intake system Exhaust system Fuel filling System Hydraulic filling system Tires Fire suppression systems Electric power pack Wheel chocks Boom greasing system Breaker greasing system Dust suppression system Breakers Breakers Tools

Open the catalog to page 3

TM15 - LP15 ARW Mobile Rockbreaker Protective Structures Options Standard Operator Compartment Tramming & Rockbreaking Specifications Turning Radius Turning radius: +/- 45° articulation Boom should remain in-line with the carrier during tramming for optimum stability. Outside Turning Radius 20’ 4” (6.2 m) Standard dual compartments for operator and passenger. Optional Operator Compartments Inside Turning Radius 10’ 9” (3.3 m) 8’ 4” (2.54 m) 10.00 x 20 tires 8’ 6” (2.59 m) 12.00 x 20 tires Recommended Drift Height BTI recommends a minimum drift height with cab: 9’-10” (3 m) ROPS/FOPS Canopy...

Open the catalog to page 4All Breaker Technology catalogs and technical brochures

-

QS Series Quarry Scalers

3 Pages

-

ALBT Series ANFO Loaders

2 Pages

-

VZ series Hydraulic Breakers

2 Pages

-

TB-XC SERIES BOXED BREAKERS

2 Pages

-

BTI's Full Line brochure

6 Pages

-

TTX Rockbreaker Systems

50 Pages

-

MRXT Rockbreaker Systems

44 Pages

-

MRX Rockbreaker Systems

8 Pages

-

MRH Rockbreaker Systems

50 Pages

-

MRHT Rockbreaker Systems

50 Pages

-

RMS18 - Hammer Scaler

12 Pages

-

EXC Mechanical Pulverizers

1 Pages

-

MS Series

2 Pages

-

SH hydraulic Shear - Eagle 2

1 Pages

Archived catalogs

-

TB series Hydraulic Breakers

2 Pages

-

MCP series Hydraulic pulverizers

2 Pages

-

HS series Hydraulic shears

2 Pages