Catalog excerpts

BRAN LUEBBE AN SPX BRAND

Open the catalog to page 1

AutoBlend The complete solution for higher productivity and product quality Turn-key metering and blending systems for the production of high-value products using liquids, pastes and powders. Our Focus: The Customer’s Needs Our dedicated systems engineers develop the best possible solutions for your needs, either from our extensive range of standard systems or individually designed and manufactured to your specification. The wide range of proven key components manufactured by SPX Process Equipment means that installations are almost completely assembled from our own products - the accurate...

Open the catalog to page 2

Reduce costs, increase quality AutoBlend installations can dramatically improve productivity and reduce running costs. All Bran+Luebbe installations meet the highest standards of quality and reliability. From conception to production, with these products and more… • Food • Cosmetics and • Special • Drinks • Chemicals - Fruit Juice - Vitamin - Brandy - Vodka - Liqueurs Margarine Mayonnaise Dressings Sauces Ketchup Syrups Confectionery Chocolate Yogurt Shampoo Body Lotion Household Cleaners Fabric Softener Liquid Soap and Detergent - Shoe Polish - Alkyl Ether Sulphate Solutions - Sulphonic...

Open the catalog to page 3

Versatility and Flexibility AutoBlend installations are used in all kinds of industries and processes - food, chemicals, cosmetics and pharmaceuticals, batch or continuous production, semi- or fullyautomatic operation, single or multiple products. AutoBlend installations are made to measure. Process Visualization Operating Protocol Recipe Management Data Storage Process control is at the heart of production management. Most AutoBlend installations employ fully automatic control, using Bran+Luebbe hardware and software tools adapted to the application. The most basic type of system control...

Open the catalog to page 4

Batch or Continuous? There is often no clear-cut answer to whether a particular process is better suited to batch or continuous production. Our experts can draw on Bran+Luebbe’s wide experience of process automation to advise you. Some of the decision factors and advantages for each method are shown below. • Optimized sterile-in-place (SIP) and clean-in-place (CIP) procedures • High capacity with low space requirement Batch Processes For high variation in recipes: Continuous Processes • High flexibility For little variation in recipes: • Easy to control • Simple procedure • Just-in-time...

Open the catalog to page 5

AutoBlend Body Lotion Production Type: Capacity: Metering and mixing system for body lotion Continuous production of high quality body lotion with a Bran+Luebbe metering and mixing system. Emulsification with a Bran+Luebbe PENTAX mixer. End-product cooling in a tube heat exchanger. Computercontrolled system with mass flow meters and flow stream monitoring. Aseptic design with CIP cleaning system. • No air introduction to finished product • Continuous production enables sterile operation and direct dispatch to the filling station • Constant product quality • Flow-through cleaning and...

Open the catalog to page 6

• 1 Type H2 metering pump with electric delivery volume control plunger pump head • 4 Type P metering pumps with electric delivery volume control, 4 plunger pump heads (1 pump head heated) • 1 PENTEX dynamic mixer Fully automatic process control • Recipe and product management with data report • Automatic product monitoring with control loop • Automatic shut-down if any ingredient runs out • 3 pipe heat exchanger in sanitary design • 1 on-line mass flowmeter • 1 on-line pH-analyzer • 1 on-line viscosity analyzer • Automatic valves

Open the catalog to page 7

AutoBlend Shampoo Production Type: Capacity: Metering and mixing system for shampoo The AutoBlend shampoo installation was developed by Bran+Luebbe for the continuous production of cosmetics without preservatives. The main components are delivered by rotary pumps with flow meters, the minor ingredients by metering pumps. The PENTAX mixer ensures a homogenous product. Advantages • Continuous production enables sterile operation and direct dispatch to the filling station • High capacity • No air introduction to finished product • Constant product quality The process runs fully automatically...

Open the catalog to page 8

• 1 NOVADOS Type H4 metering pump • 4 NOVADOS Type P metering pumps with electric delivery volume control • Automatic product monitoring with control loop Fully automatic process control • Automatic shut-down if any ingredient runs out • 1 PENTEX dynamic mixer • 1 on-line pH-analyzer • 1 on-line viscosity analyzer • 4 on-line mass flowmeters • Rotary pumps, automatic valves etc. Simplified Process Diagram Raw Material Finished Product Cleaning Solution from CIP Syst

Open the catalog to page 9

AutoBlend Dye System (Any Additive) Type: Capacity: Metering and mixing system for dyes This installation uses a metering pump with 6 pump heads. The proportion of each dye in the mixture is controlled by adjusting the pump stroke. The motor speed is regulated proportionally to the speed of the paper production machine. The dye intensity can be adjusted by altering the ratio of the pump speed to the paper machine speed. The dye mixture may be diluted with a high volume of water immediately after delivery, to simplify transport and mixing. Automatic recipe adjustment can be provided by...

Open the catalog to page 10

• 6 NOVADOS Type P metering pumps with electrical delivery, volume adjustment, 6 plunger pump heads Automatic shut-down if any ingredient runs out • 6 flow meters • 6 valve mixers • Variable speed drive motor Simplified Process Diagram

Open the catalog to page 11

Global Headquarters: SPX Process Equipment, Delavan, WI USA Bran+Luebbe, Headquarters Norderstedt, Germany Your local contact: SPX Process Equipment, Bran+Luebbe Operation 611 Sugar Creek Road, Delavan, WI 53115 Phone: (800) 252-5200 or (262) 728-1900, Fax: (262) 728-4904 E-mail: bl@spx.com For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.spxpe.com. SPX Corporation reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and...

Open the catalog to page 12All Bran+Luebbe catalogs and technical brochures

-

NOVADOS H4

2 Pages

-

NOVADOS H1

2 Pages

-

NOVADOS Metering Pumps

3 Pages

-

nOVaDOS h1 metering pumps

2 Pages

-

NOVALINK-CSM 2

4 Pages

-

ProCam Smart Metering Pumps

4 Pages

-

ProCam Metering Pumps

7 Pages

-

ISIS II

2 Pages

-

In-Line Filtration

2 Pages

-

PowerMon Compact

2 Pages

-

PowerMon S

2 Pages

-

PowerMon Ionometer

2 Pages

-

PowerMon

4 Pages

-

CeraClean

2 Pages

-

Product Overview

8 Pages

-

NOVAPLEX Vector

4 Pages

-

PowerMon Titrometer - BL-166

2 Pages

-

PowerMon Ionometer - BL-162

2 Pages

-

PowerMon - BL-161

6 Pages

-

Oxygen Sensor

2 Pages

-

Temperature Sensor

2 Pages

-

Turbidity Sensor

2 Pages

-

pH Sensor

2 Pages

-

Conductivity Sensor LFS 806

2 Pages

-

BlueBox Analyzer

4 Pages

-

Ultrafiltration

2 Pages

-

PowerMon Silikometer

2 Pages

-

Novados CS

2 Pages

-

Novados C

2 Pages

-

Novados J

2 Pages

-

ProCam Smart

6 Pages

-

ProCam Metering Pumps

16 Pages

-

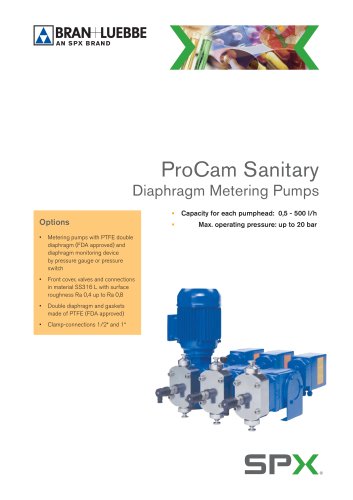

ProCam Sanitary

2 Pages

-

NOVADOS Vertical

2 Pages

-

NOVADOS KK

2 Pages

-

NOVADOS BS

2 Pages

-

NOVADOS H1

2 Pages

-

NOVADOS H-Series

2 Pages

-

NOVADOS Metering Pumps

5 Pages