Catalog excerpts

for pressing and joining applications

Open the catalog to page 1

Product description Technical data General information Electromechanical cylinder EMC 8 IndraDyn S - MS2N servo motors 12 HCS01 drive controller 14 HSZ01 safety zone module 15 PR21 industrial PC 16 Force sensor 18 Accessories 20 Software General information 21 Dashboard 22 Sequence creation 22 Process and data 23 Reference curves and curve evaluation 23 Interfaces 24 Ordering code Additional documentation

Open the catalog to page 3

Smart Function Kit | Product description Product description The Smart Function Kit mechatronic building system is suitable for numerous pressing and joining applications. ▶ Observe the safety instructions in the manual R320103194. The web-based software allows for both easy creation of a sequence by means of drag & drop of sequential modules and for the recording of the force/path development and its subsequent evaluation (OK/NOK) by envelopes, windows and limit values. The Smart Function Kit is thus an ideal basis for system integrators and end users and can be used as a stand-alone...

Open the catalog to page 4

Product description | Smart Function Kit 5 Hardware 1 Electromechanical cylinder EMC with freely configurable travel up to 400 mm (longer travel ranges upon request). Parallel or axial motor attachment 2 Force sensor: DMS technology for cost-effective and robust force measurement 3 MS2N servo motor: with absolute encoder and holding brake 4 Motor cable 5 Sensor cable 6 IndraDrive HCS01 drive controller with integrated PLC IndraMotion MLD and STO safety function and/or Safe Motion 7 Industrial PC PR21 with integrated web server for providing the web-based operating software, with Linux...

Open the catalog to page 5

Smart Function Kit | Product description Software Software Thanks to the modern, intuitive web HMIs with modular drag-and-drop process configuration, the software is ready for immediate use, with no previous knowledge required. The straightforward process for the visual generation of all required assessment and analysis elements is practically self-explanatory. Commissioning with auto configuration ▶ Preinstalled software ▶ Wizard for easy, fast commissioning ▶ Auto parameterization of the drive controller ▶ Support for commissioning with reference run and jog mode Simple programming and...

Open the catalog to page 6

Product description | Smart Function Kit 7 Software Dashboard The dashboard provides a compact overview of the system and production status. For this purpose, the four tiles contain information on production statistics, quality evaluation of the parts produced last, on the current program progress and the current machine values. Program creation The process is created by dragging & dropping sequential modules from the library. The selected modules can afterwards be individually parameterized. For quick and easy process creation, the control bar can be displayed on the right side of any...

Open the catalog to page 7

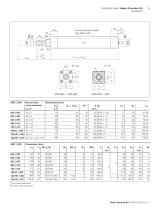

Smart Function Kit | Technical data General information Technical data General information Smart Function Kit size Nominal force Maximum force Travel path Higher values possible on request 2) Axial motor attachment 3) Parallel motor attachment Electromechanical cylinder EMC Smart Function Kit / size EMC size Screw lead Service life (on the basis of an internally defined reference cycle) Relubrication interval in spindle revolutions > 10 million cycles Million Length calculation: Overall length of EMC for motor attachment with flange and coupling = Lzs + smax + Lad + Lf + Lm Overall length...

Open the catalog to page 8

Technical data | Smart Function Kit 9 Hardware Funnel-type lube nipple DIN 3405-A M6 Rexroth ball screw assembly Axial motor attachment 2) Parallel motor attachment

Open the catalog to page 9

Smart Function Kit | Technical data Hardware Motor attachment Axial

Open the catalog to page 10

Technical data | Smart Function Kit 11 Hardware Do not exceed max. permissible screw-in depth for "M" threads Further information about motors ! Chapter "IndraD

Open the catalog to page 11

Smart Function Kit | Technical data Hardware IndraDyn S - MS2N servo motors Smart Function Kit size Axial motor attachment Parallel motor attachment Absolute value encoder Encoder type With holding brake Motor representation, schematic Motor code

Open the catalog to page 12

Technical data | Smart Function Kit 13 Hardware Version ▶ 2-cable motor connection ▶ With holding brake ▶ Plain shaft without shaft seal ring ▶ Multi-turn encoder ▶ Standard encoder (B) in conjunction with 2-cable connection (Hiperface interface) ▶ IP64 enclosure protection class ▶ Special ground connection terminal near motor flange (used as needed) Motor data Type code

Open the catalog to page 13

Smart Function Kit | Technical data Hardware (with integrated control system) Smart Function Kit / size Axial motor attachment Size Parallel motor attachment Mains connection voltage Maximum current (output-side) Axial motor attachment Parallel motor attachment 1 x AC ‒ 110 ... 230 V 3 x AC 200 ... 500 V 110 ... 230 V Axial motor attachment A 8 13 Parallel motor attachment A Single-phase, without mains choke A ‒ 8.3 1) Power inlet Continuous current Three-phase, ILN at ULN_rated without and PDC_cont mains choke Profinet, Ethernet/IP, EtherCAT, Sercos III IP20 Field bus interface Protection...

Open the catalog to page 14

Technical data | Smart Function Kit 15 Hardware HSZ01 safety zone module In the drive controller option S4, the safety zone module HSZ01.1 is used in addition Also included in the scope of delivery: 2 x bus cable, 1 m length Designation Protection class Not permissible (They prevent conductive contamination, e.g. due to the installation of the devices in control cabinets of the protection class IP54 to IEC529.) Conductive contamination Vertically in a control cabinet Permissible installation position Minimum distance from the top of the device Minimum distance from the bottom of the device...

Open the catalog to page 15

Smart Function Kit | Technical data Hardware PR21 industrial PC Operating system Linux Ubuntu Core Mass storage 1 × USB 3.0 2 × Realtek RTL8111E GbE Ethernet 1 × HDMI video port RTC battery button cell BR2032 Input voltage range Power consumption Protection class

Open the catalog to page 16

Technical data | Smart Function Kit 17 Hardware

Open the catalog to page 17

Smart Function Kit | Technical data Hardware Force sensor Features ▶ Corrosion-resistant stainless steel version ▶ High reproducibility ▶ Easy mounting directly at the EMC piston rod Note ▶ If the process requires joining to a specified force value, a force sensor is required as otherwise, no stable process result can be achieved. ▶ Calibration certificates available upon request. Metrological specifications Smart Function Kit / size Measurement technology Compressive force measuring range Traction force measuring range Protection type Operating load (of the measuring range) Breaking load...

Open the catalog to page 18All Bosch Rexroth - Linear Motion Technology catalogs and technical brochures

-

Roller rail systems_2022

206 Pages

-

Screw assemblies

280 Pages

-

Ball Transfer Units

36 Pages

-

Linear Modules

164 Pages

-

Electromechanical Cylinder EMC

60 Pages

-

High-Speed Ball Rail Systems

16 Pages

-

eLINE Compact Modules

72 Pages

-

Cam Roller Guides

56 Pages

-

eLINE Profiled Rail Systems

36 Pages

-

Roller Rail Systems

168 Pages

-

Integrated Measuring System

28 Pages

-

Kugelschienenführungen

264 Pages

-

Feed Modules VKK

48 Pages

Archived catalogs

-

Roller Rail Systems82016

216 Pages