Catalog excerpts

Electric Drives Linear Motion and and Controls I Hydraulics I Assembly Technologies Rexroth Bosch Group Hydraulic cylinders Mill typeSeries CDH1 / CGH1 / CSH1Component series 3X Nominal pressure 250 bar (25 MPa) RE 17332/07.17 1/74 Table of contents Contents Features 1 Project planning software ICS 3 Diameters, areas, forces, flow 4 Overview types of mounting: Series CDH1 and CGH1 5 Ordering code series CDH1 and CGH1 6 ... 9 Types of mounting and dimensions CDH1 and CGH1 10 ... 21 Ordering code, overview of types of mounting CSH1 22, 23 Types of mounting and dimensions CSH1 24 ... 35 Subplates for valve mounting 38 ... 41 Bleeding / measuring coupling 42 Position measurement system 46 ... 48 Features - 6 types of mounting - Piston 0 (0AL): 40 to 320 mm - Piston rod 0 (0MM): 22 to 220 mm - Stroke lengths up to 6 m - Self-adjusting and adjustable end position cushioning Swivel head CGAK 52, 53 Swivel head CGAS 54, 55 Admissible stroke length 56 ... 58 Selection criteria for seals 62 Spare parts: Series CDH1 69 Spare parts: Series CGH1 70 Spare parts: Series CSH1 MP3 and MP5 71 Project planning software Interactive Catalog System

Open the catalog to page 1

2/74 Bosch Rexroth AG | Hydraulics Standards: Bosch Rexroth standard; main dimensions like piston 0 and piston rod 0 correspond to ISO 3320. Static test pressure: 375 bar Reduced test pressure: 315 bar The maximum operating pressures must be less than or equal to the applicable nominal pressures and apply to applications with shock-free operation with reference to excess pressure and/or external loads. With extreme loads like e.g. high sequence cycle, mounting elements and threaded piston rod connections must be designed for durability. Minimum pressure: Depending on the application,...

Open the catalog to page 2

Hydraulics | Bosch Rexroth AG Technical data (For applications outside these parameters, please consult us.) Boundary and application conditions: • The mechanical alignment of the movement axis and thus the mounting points of hydraulic cylinder and piston rod must be ensured. Lateral forces on the guides of piston rod and piston are to be avoided. It may be necessary to consider the own weight of the hydraulic cylinder (MP3/MP5 or MT4) or the piston rod. • The bending length/bending load of the piston rod and/or the hydraulic cylinder must be observed (see page topic Kinking). • The maximum...

Open the catalog to page 3

4/74 Bosch Rexroth AG | Hydraulics 1 Theoretical, static cylinder force 2) Stroke velocity (without consideration of the efficiency and admissible load for attachment parts such as swivel heads, plates, or valves, etc.) Not standardized 2 Including stroke length 3) Stroke tolerances must not be added to the tolerances listed in this table.

Open the catalog to page 4

Overview types of mounting: Series CDH1 and CGH1 CDH1 MP3 see page 10, 11

Open the catalog to page 5

6/74 Bosch Rexroth AG | Hydraulics additional options, do not fill fields for additional options Z = Additional options, fill fields for additional options Seal design For mineral oil HL, HLP and HFA M = Standard seal system L = Standard seal system with guide rings R = Reduced friction heavy industry For mineral oil HL, HLP, HFA and water glycol HFC G = Standard seal system HFC T = Servo quality/ reduced friction A = Chevron seal kits For phosphate ester HFD-R and polyol ester HFD-U S = Servo quality/ reduced friction V = Standard seal system FKM B = Chevron seal kits End position...

Open the catalog to page 6

Ordering code series CDH1 Additional options Fields for additional options Z Without inductive proximity switches Inductive proximity switches without mating connector Mating connector, separate order, see page 44 Without additional guide rings Additional guide rings Without measuring coupling Measuring coupling, on both sides Standard conical grease nipples, DIN 71412 form A Spherical bearing, maintenance-free Flanged grease nipples, DIN 3404 form A without test certificate with acceptance test certificate 3.1 based on EN 10204 without oil filling with oil filling Priming class CP3...

Open the catalog to page 7

8/74 Bosch Rexroth AG | Hydraulics Option W = Without additional options, do not fill fields for additional options Z = Additional options, fill fields for additional options Seal design For mineral oil HL, HLP and HFA M = Standard seal system L = Standard seal system with guide rings R = Reduced friction heavy industry For mineral oil HL, HLP, HFA and water glycol HFC G = Standard seal system HFC T = Servo quality/reduced friction A = Chevron seal kits For phosphate ester HFD-R and polyol ester HFD-U S = Servo quality/reduced friction V = Standard seal system FKM B = Chevron seal kits...

Open the catalog to page 8

Ordering code series CGH1 Additional options Fields for additional options Z Without inductive proximity switches Inductive proximity switches without mating connector Mating connector, separate order, see page 44 Without additional guide rings Additional guide rings Without measuring coupling Measuring coupling, on both sides Standard conical grease nipples, DIN 71412 form A Spherical bearing, maintenance-free Flanged grease nipples, DIN 3404 form A without test certificate with acceptance test certificate 3.1 based on EN 10204 without oil filling with oil filling Priming class CP3...

Open the catalog to page 9

CDH1 MP3: with seal design "A", "B" and ØAL 160 to 200 mm

Open the catalog to page 10

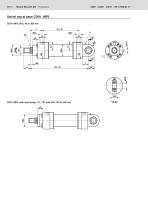

Hydraulics | Bosch Rexroth AG 11/74 0AL = Piston 0 0MM = Piston rod 0 X* = Stroke length 1) Bleeding: With view to the piston rod, the position is offset by 90° in relation to the line connection (clockwise) 3) Throttle valve only with end position cushioning "E" (180° for bleeding) 4) Flange connections see separate table pages 36 and 37 7) Dimensions for cylinders with seal design M, T, G, L, R, S and V 8) Dimensions for cylinders with seal design A and B 11) Standard version "W" Lubricating nipple, cone head form A according to DIN 71412 16) Line connection "B" and "C" 17) Line...

Open the catalog to page 11

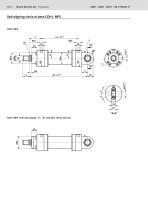

Self-aligning clevis at base CDH1: MP5 "A-A" CDH1 MP5: with seal design "A", "B" and ØAL 160 to 320 mm

Open the catalog to page 12All Bosch Rexroth - Industrial Hydraulics catalogs and technical brochures

-

Check valve Type Z1S

12 Pages

-

Hydraulic cylinders Mill type

80 Pages