Catalog excerpts

Radial piston hydraulic motor Hägglunds CBp Valid for ▶▶ Torque range: up to 280 kNm [up to 206 517 lb-ft] ▶▶ Speed range: up to 400 rpm ▶▶ Power range: up to 3166 kW ▶▶ Maximum operating pressure: 350 bar [5 076 psi] ▶▶ Frame size: 140, 280, 400, 560, and 840 ▶▶ Displacement: 5 024 to 52 800 cm3/rev [303,6 to 3220 in3/rev] ▶▶ Specific torque: 80 to 840 Nm/bar [4 068 to 42 700 ft-lbs/1 000 psi] ▶▶ Very high power density ▶▶ High torque density ▶▶ High power output ▶▶ Flexible, many sizes, few mechanical interfaces ▶▶ Front mounting possibility ▶▶ Insensitive for shock loads ▶▶ Very low moment of inertia ▶▶ Small footprint (total occupied volume) ▶▶ Freewheeling possibility ▶▶ Through hole diameter up to 170

Open the catalog to page 1

Hägglunds CBp | Radial piston hydraulic motor Ordering code In order to identify Hägglunds equipment exactly, the following ordering code is used. These ordering codes should be stated in full in all correspondence e.g. when ordering spare parts. Example Hägglunds CBp motor: CB Motor series Compact Type High Power Nominal size , specific torque, Nm/bar (see section 4.3) Frame size 140 Frame size 400 Frame size 560 Frame size 840 Motor prepared for multi disc brake or tandem kit Motor not prepared for brake or tandem kit Motor prepared for brake Mounting alternatives, shaft Splines...

Open the catalog to page 2

Radial piston hydraulic motor | Hägglunds CBp 3/64 Type of seal NBR (Nitrile( Through hole kit (see section 5) No Increased robustness (see section 6) No Modification Standard Design Standard Special index ● = Available 1) 2) Only CBp 140 Contact Technical help desk! Only CBp 280 to CBp 840

Open the catalog to page 3

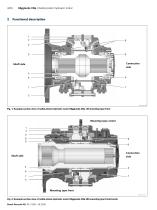

Hägglunds CBp | Radial piston hydraulic motor Functional description Shaft side Fig. 1: Example section view of radial piston hydraulic motor Hägglunds CBp 140 mounting type front Shaft side Mounting type front DD0012101 Fig. 2: Example section view of radial piston hydraulic motor Hägglunds CBp 560 mounting type front/center Bosch Rexroth AB, RE 15301, 09.2020

Open the catalog to page 4

Radial piston hydraulic motor | Hägglunds CBp 5/64 axial and radial bearing 4. Cylinder block, spline Cylindrical roller bearing 7. Connection housing 8. Distributor 9. Wear ring When the hydraulic pressure is acting on the pistons, the cam rollers are pushed against the slope on the cam ring that is rigidly connected to the housing, thereby producing a torque. The cam rollers transfer the reaction force to the pistons which are guided in the cylinder block. Rotation therefore occurs, and the torque available is proportional to the pressure in the system. Oil main lines are connected to...

Open the catalog to page 5

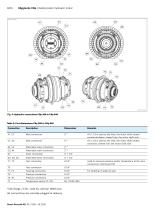

Hägglunds CBp | Radial piston hydraulic motor Fluid connections Port locations and dimensions, see Table 1, Table 2, Fig. 4 and Fig. 5

Open the catalog to page 6

Radial piston hydraulic motor | Hägglunds CBp 7/64 Connection side of the motor Shaft side of the motor Fig. 4: Hydraulic connections CBp 140 Table 1: Port dimensions CBp 140 Connection Main connection If A1, C3 is used as the inlet, the motor shaft rotates counterclockwise, viewed from the motor shaft side Main connection If C1, A3 is used as the inlet, the motor shaft rotates clockwise, viewed from the motor shaft side Alternative main connection Alternative main connection Drain connection Alternative drain connection Temperature sensor normally mounted in D2 (T7) Test connection Used to...

Open the catalog to page 7

Hägglunds CBp | Radial piston hydraulic motor Table 2: Port dimiensions CBp 280 to CBp 840 Connection Main connection If A1, C3 is used as the inlet, the motor shaft rotates counterclockwise, viewed from the motor shaft side Main connection If C1, A3 is used as the inlet, the motor shaft rotates clockwise, viewed from the motor shaft side Alternative main connection Alternative main connection Drain connection Alternative drain connection Test connection Test connection Flushing connection Pressure connection Pressure connection *SAE flange J 518 , code 62, 420 bar (6000 psi). All...

Open the catalog to page 8

Radial piston hydraulic motor | Hägglunds CBp 9/64 Technical data 4.1 Calculation fundamentals Table 3: Calculation fundamentals. Metric Output power Flow rate required Output speed Inlet power 9549 Ts⋅(p-∆pl-pc )⋅ηm T Ts⋅ηm n ⋅ Vi 1000 q - ql Vi q⋅(p-pc ) 600 Output torque Specific torque Rotational speed Required pressure Pressure loss Charge pressure Flow rate required Total volumetric loss Mechanical efficiency 5252 Ts⋅(p-∆pl-pc )⋅ηm 1000 T⋅1000 Ts⋅ηm n ⋅ Vi 231 q - ql Vi q⋅(p-pc ) 1714

Open the catalog to page 9

Hägglunds CBp | Radial piston hydraulic motor 4.2 General data Table 4: General data (metric) Frame size CBp 140 See section 8: Mounting alternatives Port connections See section 3.2: Port connections External loads See section 4.14: Permissible external loads Hydraulic fluids Pressure See section 4.5: Hydraulic fluids Maximum operating pressure Maximum peak pressure Charge pressure Maximum case pressure See section 4.4: Recommended charge pressure For continuous duty, the service life of the shaft seal is affected by case oil temp, case pressure and speed, see Fig. 6 and Fig. 7 Maximum...

Open the catalog to page 10

Radial piston hydraulic motor | Hägglunds CBp 11/64 Viton @ 50 °C in motor case Viton @ 65 °C in motor case Speed [rpm] Fig. 6: Maximum case pressure vs. speed, continuous operation for CBp 140 Viton @ 50 °C in motor case Viton @ 65 °C in motor case Speed [rpm] Fig. 7: Maximum case pressure vs. speed, continuous operation for CBp 280 to CBp 840

Open the catalog to page 11

Hägglunds CBp | Radial piston hydraulic motor 4.3 Motor data Table 6: Specific data (metric) Frame size Specific torque Displacement Maximum speed Maximum operating pressure 2) Maximum operating power 3) Nominal size Calculated as: Metric = Ts • (350-15) • 0,98 The motors are designed according to DNV-rules. Test pressure 420 bar. Peak pressure 420 bar maximum, allowed up to 10 000 times. 3) Flushing of motor case is required. See section 4.10: Flushing 4) Alternating torque direction is not allowed for front mounting flange. 1) 2)

Open the catalog to page 12