Website:

Bosch Rexroth Components for Mobile Robotics

Website:

Bosch Rexroth Components for Mobile Robotics

Group: BOSCH REXROTH

Catalog excerpts

BODAS Inertial sensor MM7.10 ▶ MEMS inertial sensor ▶ 3 acceleration and 3 rotation rate signals ▶ Output signal CAN (ISO 11898) ▶ Supply voltage 8 to 16 V ▶ Protection class IPX6K, IPX7K, IPX9k ▶ CE conformity The inertial sensor is available as MM7.10 and MM7.10AC. Contents Product description Ordering code Technical data Angle output Electrical connection Project planning notes Safety-related characteristics according to ISO 25119 Application guidelines Safety instructions

Open the catalog to page 1

MM7.10 | BODAS Inertial sensor Product description Product description The inertial sensor is available as MM7.10 and MM7.10AC. Description MM7.10 and MM7.1AC The purpose of the inertial sensor is to measure the physical effects of the yaw rate, rate of roll, and of transverse, longitudinal and vertical acceleration. When mounted appropriately (i.e. according to the offer drawing), the sensor measures the yaw and roll rates as well as the lateral, longitudinal and vertical acceleration of the vehicle. In order to prevent signal interference or negative power supply impacts on the sensor,...

Open the catalog to page 2

BODAS Inertial sensor | MM7.10 Ordering code Type 01 Inertial sensor Address Claiming 02 Without Address Claiming (without code) With Address Claiming Baud rate 03 250 kBaud Available variants MM7.10 Adress Claiming Material number Configurable parameters: Baud rate, CAN ID, CAN message deactivation, CAN update rate, Big/Little Endianess format, Identifier Length, Band- Other variants on request. Material number width signal filter (frequency limit), No_Ack timing and Bus_Off timing. Bandwidth signal filter (frequency limit) 08 15 Hz

Open the catalog to page 3

MM7.10 | BODAS Inertial sensor Technical data Technical data Ambient conditions Parameters Storage time Service life Operation time (UZ on) with the following temperature distribution Operating temperature range Temperature gradient Room temperature Protection class Functional safety Environmental requirements and test requirements for earth-moving According to DIN EN ISO 19014- 3:2018 machinery Electrical data Parameters Typical nominal voltage Supply voltage Fault-free supply voltage Maximum supply current at 7 V Maximum supply current at 14 V Short-circuit protection output Direct...

Open the catalog to page 4

BODAS Inertial sensor | MM7.10 Technical data ▼ Block circuit diagram Voltage controller Down converter Elko For compliance with Load Dump 5a according to ISO 16750-2, it is required to install a load dump diode in the vehicle electrical system of the higher-level system (machine). Yaw and roll rate output Parameters Nominal measurement range Overload limit Sensitivity error at ϑop within tlife Ωx,y,z: Offset, absolute within tlife, measured with ϑop Rate of change, offset t < 3 min after Usup on Rate of change, offset t > 3 min after Usup on Time until availability Sensitivity of the...

Open the catalog to page 5

MM7.10 | BODAS Inertial sensor Angle output Radiated susceptibility to interference (interference immunity) Parameters Conductor track test according to ISO 11452-5 BCI test according to ISO 11452-4 Absorber chamber test according to ISO 11452-2 Mobile phone test according to ISO 11452-9 Radiated susceptibility to interference (radiation) Parameters Antenna measurement according to CISPR 25-13 There is further technical data in the TCD ("Technical Customer Documentation" 95178_TCD_MM7.10 / 95179_TCD_MM7.10_Address_Claiming). Angle output The inertial sensor can realize an angle output in...

Open the catalog to page 6

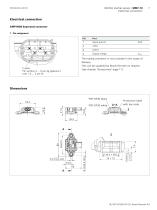

BODAS Inertial sensor | MM7.10 Electrical connection Electrical connection AMP-MQS Superseal connector ▼ Pin assignment Signal ground Supply voltage The mating connector is not included in the scope of delivery. This can be supplied by Bosch Rexroth on request CuSn6 Pin surface 3 ... 6 µm Ag (galvanic) over 1.3 ... 3 µm Ni (see chapter "Accessories" page 11). Production label

Open the catalog to page 7

MM7.10 | BODAS Inertial sensor Project planning notes Project planning notes Installation position Acceleration and rotation rate Normal position of the inertial sensor: ▶ connector facing away from direction of travel ▶ For a definition of the axes, see chapter - Assembly (vehicle axis system) Upper limit Vehicle axis system +Zsensor Lower limit Vehicle axis system according to DIN 70000 or ISO 8855: + Xvehicle is aligned with the front of the vehicle + Yvehicle is aligned with the left side of the vehicle + Zvehicle is aligned with the vehicle roof If the sensor is installed in the...

Open the catalog to page 8

BODAS Inertial sensor | MM7.10 Installation in the vehicle Installation in the vehicle The inertial sensor must be fastened with two screws prior Spectrum during fixing to operation. The appropriate size can be found in the During the fixing on the vehicle, the housing of the inertial offer drawing. sensor is exposed to various influences, e.g. due to the The tightening torque for the M6 nut is defined in the offer drawing. Fixing the bolts with impact wrenches is not allowed as the high impact force of the wrench and resulting fixing and the tools. These values, which are determined by a...

Open the catalog to page 9

MM7.10 | BODAS Inertial sensor Safety-related characteristics according to ISO 25119 and ISO 13849 Safety-related characteristics according to ISO 25119 and ISO 13849 The safety function of the inertial sensor is defined as ▶ The inertial sensor has a category 2 architecture system integrity, i.e. the inertial sensor shall measure the (one single channel with external monitoring unit) physical effects (roll rate, pitch rate, rotation rate, ▶ The inertial sensor meets the requirements of the basic transverse acceleration, longitudinal acceleration and and well-tried safety principles...

Open the catalog to page 10

BODAS Inertial sensor | MM7.10 Application guidelines Use in safety-related functions ▶ The customer is responsible for the preparation of a risk analysis of the machine and for the definition of possible safety functions of the machine. ▶ The customer is responsible for evaluating the entire safety-relevant machine system and for determining the suitability of the inertial sensor for safety functions of the machine: – The inertial sensor meets the requirements of ISO 25119:2018 AgPL d and ISO 13849 PL d when properly integrated into the machine's safety system in accordance with all...

Open the catalog to page 11All Bosch Rexroth Components for Mobile Robotics catalogs and technical brochures

-

Press module for die cushion

24 Pages

-

Accumulator modules

16 Pages

-

BODAS Pressure sensor PR4

32 Pages

-

Filtermatte

2 Pages