Website:

Bolte GmbH

Website:

Bolte GmbH

Catalog excerpts

improved process monitoring elding simplified oring of all w trol by monit on ction production c t visual inspe d subsequen an parameters ing of stud d fast adjust ble, exact an g head comforta matic weldin un resp. auto welding g cess cycle optimised pro INVERTER STUD WELDING UNIT FOR DRAWN ARC AND SHORT CYCLE STUD WELDING SINGLE-PHASE POWER SUPPLY (230 V OR 115 V) STUD WELDING TECHNOLOGY BY STUD WELDING

Open the catalog to page 1

EASY OPERATION BY ROBUST ROTATING PRESSURE SWITCH MODERN INVERTER TECHNOLOGY ENSURES VERY PRECISE CONTROL AND HIGH REPRODUCIBILITY OF THE WELDING PROCESS WELDING CURRENT AND TIME CONTINUOUSLY ADJUSTABLE VERY HIGH ARC STABILITY! ALSO IN CASES OF SHORT WELDING TIMES AND LOW WELDING CURRENTS SINGLE-PHASE POWER SUPPLY (230 V OR 115 V) ALL FUNCTIONS AND PARAMETERS ARE SHOWN ON A BIG DISPLAY IDEALLY SUITED FOR MOBILE USE CONSIDERABLY LOWER WEIGHT THAN CONVENTIONAL STUD WELDING UNITS UNAFFECTED BY FLUCTUATIONS IN THE MAINS VOLTAGE ROBUST CONSTRUCTION FOR THE USE IN HARSH ENVIRONMENTS CONTROLLING...

Open the catalog to page 2

HIGHLIGHTS AND SPECIAL EQUIPMENT WELDING PARAMETER MONITORING AND DOCUMENTATION The welding parameter monitoring, integrated as standard in all series PRO-S stud welding units, enables a quality control of the finished welds. The units can detect each discrepancy from the ideally permitted values. So the welding supervisor and the operator can immediately recognise deficits in the welding operation like insufficient balancing of blowout effects, tilt of the welding gun etc. Consequently, the production control can be reduced to monitoring and recording of all welds by the unit and a...

Open the catalog to page 3

AUTOMATIC STUD FEEDING » An automatic module enables the connection of the automatic stud feeder VBZ and an automatic welding gun. ADAPTER BOX PRO-SPLIT » available as accessory » automatic detection of used gun » enables the operation of up to four stud welding guns with different adjustment values for welding current and time on one unit » weld counter for each gun connection » with up to four shielding gas modules SHIELDING GAS MODULE FOR STUD WELDING WITH SHIELDING GAS » optionally available » enables stud welding with shielding gas for weld pool backing » shielding gas pre- and...

Open the catalog to page 4

TECHNICAL DATA AND CHARACTERISTICS PRO-S 600 Welding range (Ø mm) Stud welding with ceramic ferrule Stud welding with shielding gas Short cycle stud welding with or without shielding gas Thermic controlled ventilator Robust, powder-coated metal housing Welding parameter monitoring Welding parameter monitoring Welding parameter memory with USB-interface for data transmission to a PC Utilisable with adapter box PRO-SPLIT Operation Microprocessor control Welding programme library Welding programme storage Device lock with PIN code Authorization concept (device lock, basic settings, menu...

Open the catalog to page 5

© Bolte GmbH Last update 08/21. Texts and illustrations correspond with technical standard at the date of printing. Errors and omissions excepted.

Open the catalog to page 6All Bolte GmbH catalogs and technical brochures

-

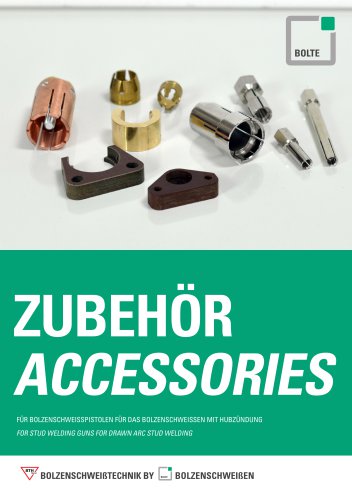

ZUBEHÖR ACCESSORIES

104 Pages

-

PKA-500 PHA-500 PHA-500-6

4 Pages

-

VBZ

4 Pages

-

KKA-200F KHA-200F

4 Pages

-

SERIES V

6 Pages

-

SERIES T

6 Pages

-

PIM-1B PIM-1K

4 Pages

-

PKM-1B PHM-1A

4 Pages

-

GD

6 Pages

-

PHM

4 Pages

-

LBS

6 Pages

-

PRO-I

8 Pages

-

PRO-D

6 Pages

-

SHEAR CONNECTORS

4 Pages

-

BOLTE GmbH

6 Pages