Website:

BODINE ELECTRIC COMPANY

Website:

BODINE ELECTRIC COMPANY

Catalog excerpts

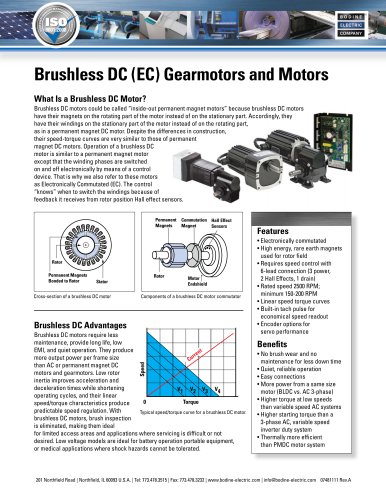

Brushless DC (EC) Gearmotors and Motors What Is a Brushless DC Motor? Brushless DC motors could be called “inside-out permanent magnet motors” because brushless DC motors have their magnets on the rotating part of the motor instead of on the stationary part. Accordingly, they have their windings on the stationary part of the motor instead of on the rotating part, as in a permanent magnet DC motor. Despite the differences in construction, their speed-torque curves are very similar to those of permanent magnet DC motors. Operation of a brushless DC motor is similar to a permanent magnet motor except that the winding phases are switched on and off electronically by means of a control device. That is why we also refer to these motors as Electronically Commutated (EC). The control “knows” when to switch the windings because of feedback it receives from rotor position Hall effect sensors. Permanent Magnets Commutation Hall Effect Magnet Sensors Rotor Permanent Magnets Bonded to Rotor Cross-section of a brushless DC motor Motor Endshield Components of a brushless DC motor commutator Brushless DC motors require less maintenance, provide long life, low EMI, and quiet operation. They produce nt rre u more output power per frame size C than AC or permanent magnet DC motors and gearmotors. Low rotor inertia improves acceleration and deceleration times while shortening V1 V2 V3 V4 operating cycles, and their linear 0 Torque speed/torque characteristics produce predictable speed regulation. With Typical speed/torque curve for a brushless DC motor. brushless DC motors, brush inspection is eliminated, making them ideal for limited access areas and applications where servicing is difficult or not desired. Low voltage models are ideal for battery operation portable equipment, or medical applications where shock hazards cannot be tolerated. Features • E lectronically commutated • High energy, rare earth magnets used for rotor field • Requires speed control with 6-lead connection (3 power, 2 Hall Effects, 1 drain) • Rated speed 2500 RPM; minimum 150-200 RPM • Linear speed torque curves • Built-in tach pulse for economical speed readout • Encoder options for servo performance Benefits • No brush wear and no maintenance for less down time • Quiet, reliable operation • Easy connections • More power from a same size motor (BLDC vs. AC 3-phase) • Higher torque at low speeds than variable speed AC systems • Higher starting torque than a 3-phase AC, variable speed inverter duty system • Thermally more efficient than PMDC motor system 201 Northfield Road | Northfield, IL 60093 U.S.A. | Tel: 773.478.3515 | Fax: 773.478.3232 | www.bodine-electric.com | info@b

Open the catalog to page 1

Standard Products Custom Solutions • Matched gearmotor-control system solutions • 12, 24, and 130 VDC motors, gearmotors, and controls • High speed (up to 20,000 RPM) motors and controls • Two-year limited warranty for matched Bodine motor-control systems • 22B/SR and 34B/FV 24VDC INTEGRAmotors provide integrated motor, control and feedback systems • 48B motor achieves up to 1.5 HP with matched speed control (type EBL) • Analog (SR) and Digital (FV) interface INTEGRAmotor options • Environmentally protected versions for OEM applications • Third-party markings, including Class I/Div 2 •...

Open the catalog to page 2All BODINE ELECTRIC COMPANY catalogs and technical brochures

-

2998

2 Pages

-

34B-WX , 33A-WX

2 Pages

-

33A7-WX

2 Pages

-

42R-5L/H

2 Pages

-

IP-66

2 Pages

-

IP-69K

2 Pages

-

STANDARD PRODUCTS 2024

52 Pages

-

PLANETARY BLDC GEARMOTORS

2 Pages

-

Bodine Electric Handbook

252 Pages

-

42R-FX AC Gearmotor

2 Pages