Catalog excerpts

Product Overview

Open the catalog to page 1

Production Metrology Made in Germany Blum-Novotest GmbH is a recognised developer of leading-edge measuring components, with more than 45 years of experience as a partner in the worldwide machine tool, automotive and aircraft industries. Our measuring technology »Made in Germany« supports customers in various industries in increasing their productivity, as well as the quality of the produced parts. As your reliable partner we are following our principles of keeping highest quality standards at competitive prices. We support you in the optimisation of your processes, and thus, help you to...

Open the catalog to page 2

= ^ Division Measuring Components Jlr Tool Setting Probes '"It Touch Probes DIGILOG '"lC Surface Roughness Gauges RG Software FormControl @J Special Measuring Systems Further Divisions Division NOVOTEST Test Engineering 54 Division Measuring and Testing Technology 55

Open the catalog to page 3

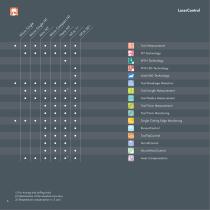

Tool Measurement NT Technology NT-H Technology NT-H 3D Technology shark360 Technology Tool Breakage Detection 2) Tool Length Measurement Tool Radius Measurement Tool Form Measurement Tool Form Monitoring Single Cutting Edge Monitoring RunoutControl ToolTipControl GrindControl MicroWearControl 1) For turning and milling tools 2) Optimisation of the absolute accuracy 3) Temperature compensation in 3 axis Axes Compensation

Open the catalog to page 4

LaserControl NT | Support Systems Unbeatably precise and reliable. In order to achieve the greatest possible accuracy in measuring tools in the machining centre, Blum recommends the use of compact support systems. The Micro Compact NT system is by default available up to a length of 1000 mm. The exceedingly compact Nano NT was designed especially for the requirements of high-end machines in micro-machining. Single Cutting Edge Monitoring Tool Breakage Detection Tool Length Measurement Tool Radius Measurement Tool Form Measurement Axes Compensation Tool Form Monitoring Nano NT – for...

Open the catalog to page 5

LaserControl NT | Single Systems Modular and precise – Micro Single NT and Mini NT are the single versions from the LaserControl NT series. The separation of transmitter and receiver allows for a flexible integration into a wide variety of machine types. They are, for instance, used if the installation of support systems is impossible due to the design of the machine tool. NT Technology Tool Breakage Detection Tool Length Measurement Tool Radius Measurement Single Cutting Edge Monitoring Axes Compensation Mini NT – highly precise single system Indispensable – the Blum pneumatic unit 100%...

Open the catalog to page 6

LaserControl NT-H 3D | Combined System The all-rounder for any tool. LaserControl NT-H 3D is a compact and highly precise system for measuring of the whole range of tools in turning-milling centres. The measurement of milling tools via laser can be carried out contact-free under nominal rotation speed. Turning tools can be measured quickly and reliably with the adapted touch probe. Thanks to built-in blowing nozzles even coolant, chips on tool or stylus are not a problem. Tool Form Monitoring Single Cutting Edge Monitoring Tool Breakage Detection Tool Length Measurement Tool Radius...

Open the catalog to page 7

Tool Setting Probes Tool Measurement Infrared Transmission Radio Transmission Hardwired Linear Working Principle shark360 Technology Wear-free Measuring Mechanism Modular System Tool Breakage Detection Tool Length Measurement Tool Radius Measurement Axes Compensation 43

Open the catalog to page 8

Tool Setting Probes Z-Series Robust and economic – the compact tool setting probes are extremely economic solutions for fast tool breakage detection and highly precise length measurements in machine tools. The well-proven design and the wear-free optoelectronic measuring mechanism with linear working principle, provide the highest reliability under the most adverse manufacturing conditions. Tool Length Measurement Infrared Transmission Axes Compensation Radio Transmission Linear Working Principle Wear-free Measuring Mechanism Tool Breakage Detection Z-Pico – for micro-machining (from 50 μm...

Open the catalog to page 9

Tool Setting Probes 3D-Series Versatile and economic – the 3D tool setting probe series comprises universally applicable probes for the measurement of length, radius and tool breakage in the machining centre. Almost all probes in the series use the proven shark360 measuring mechanism which is outstanding in its unparalleled precision and longevity. Tool Length Measurement Infrared Transmission Tool Radius Measurement Radio Transmission Axes Compensation shark360 Technology Wear-free Measuring Mechanism Tool Breakage Detection Blum infrared system with DUO- Mode Z- MT – hardwired and with...

Open the catalog to page 10

Touch Probes Workpiece Measurement Tool Measurement Infrared Transmission Radio Transmission Hardwired Multidirectional Bidirectional shark360 Technology Wear-free Measuring Mechanism Modular System Single & Mass Production Contour Measurement Pulling Measurement Axes Compensation Tool Length Measurement Tool Radius Measurement Tool Breakage Detection 63/40

Open the catalog to page 11

Faster, more economic, more precise - the advantages of this high-speed touch probe series can be summarized as simply as that. The multidirectional probes convince with the latest measuring mechanism technologies with optoelectronic signal generation, the highest measuring speed (up to 3 m/min) and a perfect, rotationally symmetrical probe behaviour without disadvantageous lobing. Infrared Transmission Axes Compensation Radio Transmission Multidirectional Wear-free Measuring Mechanism Single & Mass Production Contour Measurement Non-lobing touch characteristics TC52, TC62 – for small...

Open the catalog to page 12

Perfect for fast machining centres – the touch probes were specifically developed for the requirements of highly productive machines. The unique bidirectional measuring mechanism with optoelectronic signal generation possesses a superior accuracy and permits measuring speeds of up to 5 m/min. The TC51 and the TC61 are the only touch probes worldwide, that allow quick pulling measurements in Z+ permanently and without wear. Infrared Transmission Pulling Measurement Radio Transmission Bidirectional Wear-free Measuring Mechanism Mass Production Axes Compensation TC51, TC61 – extremely fast and...

Open the catalog to page 13All Blum-Novotest catalogs and technical brochures

-

Touch Probes TC51 | TC61

2 Pages

-

LaserControl Series

11 Pages

-

MEASURING COMPONENTS

39 Pages

-

TC64-DIGILOG

2 Pages

-

Z-Nano Tool Setting Probe

2 Pages

-

Product Overview 2011/12

25 Pages

-

TG80

2 Pages

-

Z-Nano

4 Pages

-

TC76

2 Pages

-

TC53-30

2 Pages

-

LaserControl

8 Pages