Catalog excerpts

understanding bioprocesses Automated Bio-Methane Potential (BMP) evaluation system Yield Master

Open the catalog to page 1

Understand your bioprocess with BlueSens It is our philosophy to make bioprocessing as open and user-friendly as possible so the user gets a controlled process with the highest possible process reliability. Measure in the process: no contaminations, continuous readings without interruptions No gas treatment /CO2 absorption required Automatically monitor all important process parameters (e.g. pH, pO2, etc. and not only CH4) and control actuators Real-time measurement Modular setup: adopt the system to your demands Be sure about the process conditions and highest reproducibility Save time &...

Open the catalog to page 2

The Yieldmaster is ideal to compare different substrates with each other. With this analysis system you know exactly at which time how much methane was produced. And the BlueVis software is making the measurements very convenient

Open the catalog to page 3

Know and monitor the produced CH4 volume in real time. Compare the gas yield of different substrates

Open the catalog to page 4

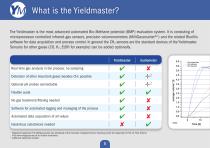

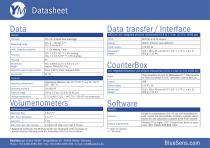

The Yieldmaster is the most advanced automated Bio-Methane potential (BMP) evaluation system. It is consisting of microprocessor controlled infrared-gas sensors, precision volumenometers (MilliGascounter®1) and the related BlueVis software for data acquisition and process control. In general the CH4 sensors are the standard devices of the Yieldmaster. Sensors for other gases (CO, H2, EtOH for example) can be added optionally. 1 Registered trademark. The MilliGascounter was developed at the University of Applied Science Hamburg under the leadership of Prof. Dr. Paul Scherer. Visit...

Open the catalog to page 5

^ Up to 12 CH4-sensors, other sensors (CO2, O2, EtOH, H2) also addable BlWater bath with integrated thermostat and water level compensation Cl Multiplexer BACCom12 with integrated pressure sensor and Counter Box BACCOM12 CB with integrated temperature sensor Dl Control unit for magnetic stirrer plate (water proof magnetic stirrer plate is inside the water bath, not shown on image) (9BlueVis software for data logging and process management FlMilliGascounter® with one-way valve g| Stirrer h!Special flow adapter POM with two gas sensors for use with preserving jars ■I Heating jacket for...

Open the catalog to page 6

Gain information about your process kinetics, substance behavior, substrate characteristics and outputs Your advantages: • No minimum gas flow required • High sample throughput • Real-time CH4 values • Monitoring metabolism phenomena • Compareable results by paralallism • Automatic data acquisition, high grade of automation

Open the catalog to page 7

Run your own automated calculations in real-time by integrated math sensors in BlueVis • Manage and analyze your process in real-time • Connect all the sensors, probes and volumenometers • Control pumps, stirrers and thermostats • Log, document and visualize all batches

Open the catalog to page 8

Manage your process with BlueVis Use the BlueVis software to manage your process. Discover the new BlueVis 4.0 to run, monitor and to control your anaerobic digestion process. With BlueVis you can manage your complete Yieldmaster system. Calculations compliant to VDI 4630 included. Configure your individual Yieldmaster system 1. elect the relevant S gases, you want to measure 5. elect a stirring S method Magnetic stirring plate or overhead stirrer Vessel flat bottom for magnetic stir bar, various round jars 6. elect additional S equipment 7. elect data S transfer 4. elect a heating S system...

Open the catalog to page 9

Blue LOGGING & VISUALIZATION PROCESS PARAMETERS

Open the catalog to page 10

fWe are using the Yieldmaster since its giving us maximum flexibility and reliability Your advantages: • Know your process: keep track of all fermenters and compare all yields at a glance • Be independent: connect different types of sensors and actuators from various brands • Be sure: have a perfect documented workflow • Be relaxed: high grade of automation • Work accordingly to the standard: Calculations compliant to VDI 4630 included

Open the catalog to page 11

** other on request *** full scale BlueSens gas sensor GmbH • Snirgelskamp 25 • 45699 Herten • Germany Phone: +49 2366 4995-500 • Fax: +49 2366 4995-599 • E-mail: info@B

Open the catalog to page 12All BlueSens gas sensor GmbH catalogs and technical brochures

-

BCpreFerm

5 Pages

-

BlueVIS 4.0

2 Pages

-

YeastForce

4 Pages

-

BlueInOne

12 Pages

Archived catalogs

-

H2 sensor BCP-H2

2 Pages

-

BlueVary

2 Pages

-

Brochure BlueInOne series

12 Pages

-

Brochure BCP-CO2 sensor

8 Pages

-

Data sheet BCP-O2

2 Pages

-

Data sheet BCpreFerm

8 Pages

-

BlueSens Brochure

6 Pages

-

Data Sheet BenchOne Biogas

2 Pages

-

BlueSens Report No.3

19 Pages

-

Brochure BlueSens 2012

6 Pages

-

REPORT 1

36 Pages