Website:

BlueSens gas sensor GmbH

Website:

BlueSens gas sensor GmbH

Catalog excerpts

BlueSens Report No. 1, October 2010 © 2010 by BlueSens gas sensors GmbH, Herten, Germany, www.BlueSens.com This report was worked out in co-operation with APZ Ruhr-Lippe, www.apz-rl.de Page layout and cover design: Marcus Riepe, Krefeld, Germany, marcus@riepe-im-inter.net Printing press: Offset Company, Wuppertal, Germany, www.offset-company.de

Open the catalog to page 2

Introduction BlueSens.com BlueSens Report No. 1 3 You may wonder why we have published a report with detailed product information and user data only recently after almost 10 successful years and several thousand sensors already sold? The answer is quite simple – time. It is only recently we have increased the human resources in our PR-department and in addition we have received the support of the APZ (center for applications Biotechnik Ruhr-Lippe) which has made it possible for us to publish now. Almost every new customer wanted this type of information however until recently we referred...

Open the catalog to page 3

Contents BlueSens.com BlueSens Report No. 1 5 6 BlueSens. Advanced information 8 Application of a self constructed off gas analyser in the education of bioengineers Dr. Michael Maurer, FH Campus Wien 10 Continuous bio-ethanol production by means of yeast Dr.-Ing. Eva Maria del Amor Villa, Technical University Dortmund 12 Model based optimization of biogas plants Dr. F. Uhlenhut, Prof. Dr. S. Steinigeweg, Prof. Dr. A. Borchert, Prof. Dr. Reiner Lohmüller, University of Applied Sciences Emden/Leer 14 Online observation of oxygen uptake and carbon dioxide production and characterisation of...

Open the catalog to page 5

For controlling biotechnological processes you primarily depend on continuous information. BlueSens has made it to its business to provide this information for every customer by means of gas analysis directly in the process. Reliable measurement engineering makes the results available in highest measurement density and in real time. So biotechnological processes can be analyzed better and, as a result, of course also optimized. With this report we also want to give you advanced information. Numerous examples of applications show exactly how the products of BlueSens are used under real...

Open the catalog to page 6

During the calibration process each sensor is tested and set up particularly. This process can take up to one week. It involves a lot of time, but it‘s worth it. In the detailed test procedure BlueSens solely uses certified test gases. Depending on the gas component to be measured, 10 to 18 different test gases are used. So it is assured that the sensors provide best results for each application the customer requires. Each sensor so becomes a handmade piece and is individually tested by BlueSens. BlueSens stands for sensors which are as uncomplicated as possible and therefore as competitive...

Open the catalog to page 7

Application Report 8 BlueSens Report No. 1 BlueSens.com Our University of Applied Sciences, FH Campus Wien, offers a degree program in ‘Bioengineering’. In the course of this study a fermentation laboratory has to be attended. The aim of this course is the design, operation and analysis of a bioprocess experiment. The students have to use their biological, mathematical and technical skills to solve this exercise. One of the experiments involved cultivation of the methylotrophic yeast Pichia pastoris (X33); a well known host for recombinant protein expression (Cregg et al. 2000), as well as...

Open the catalog to page 8

Application Report BlueSens.com BlueSens Report No. 1 9 stirrer speed between 250 and 1200 rpm and the air flow between 2.0 and 5.0 l min-1. Samples were taken frequently over the whole process and analysed as described below. Three aliquots of 10 ml of culture broth were centrifuged and the supernatant saved for HPLC analysis. The pellets were washed in distilled water and recentrifuged, transferred into weighed beakers and dried at 105°C until a constant weight was attained. The biomass concentration was also monitored with an on-line probe (Fogale nanotech, Nimes, France), which had...

Open the catalog to page 9

Application Report 10 BlueSens Report No. 1 BlueSens.com Japan) using an ion exchange column Aminex HPX-87H (Bio Rad). The mobile phase was 15 mM sulphuric acid. The aim of the exercise was the calculation of typical fermentation parameters such as biomass concentration, substrate uptake rate, specific growth rate, and so on, as well as the respiratory quotient (RQ) and the over all carbon balance (OCB). Using the universal gas equation and the recorded oxygen and carbon dioxide concentration [%] and the air flow data. The students were able to calculate the oxygen uptake rate (OUR), the...

Open the catalog to page 10

Application Report BlueSens.com BlueSens Report No. 1 11 The continuous bio-ethanol production by means of in sodium alginate entrapped Saccharomyces cerevisiae (ATCC 7752) was successfully carried out at 40°C in a stirred bioreactor with an operating volume of 600 ml by continuous substrate feed over a period of five days. The sensors were connected gastight, allowing quantitative online records on gases (carbon dioxide, ethanol and oxygen) present in the headspace of the bioreactor (see figure 1). By using a suitable calibrated ethanol sensor a direct calculation of the ethanol content in...

Open the catalog to page 11

Application Report 12 BlueSens Report No. 1 BlueSens.com Motivation Increasing amount of energy derived from biogas plants will only be available if a wide variety of different substrates can be used. The feed to a biogas reactor will change according to the fluctuating supply demand scenario for various substrates. The plant has to deliver maximum gas yield and hence energy yield for various substrates. This can only be achieved if the process parameters are optimized continuously. The model should be able to predict optimized process parameters as well as energy yield for a given...

Open the catalog to page 12

Application Report BlueSens.com BlueSens Report No. 1 13 compared to results predicted by the model (figure 2). Again just readily available parameters describing the substrate and the biogas plant have been incorporated into the process model. As can be seen a very good agreement between experimental data and data from the biogas plant have been achieved. Further research will focus on incorporating a wide variety of different substrates, to account for substrate pre-treatment and for biogas purification. Dr. F. Uhlenhut, Prof. Dr. S. Steinigeweg, Prof. Dr. A. Borchert, Prof. Dr. Reiner...

Open the catalog to page 13All BlueSens gas sensor GmbH catalogs and technical brochures

-

BlueSens General Broschuere

12 Pages

-

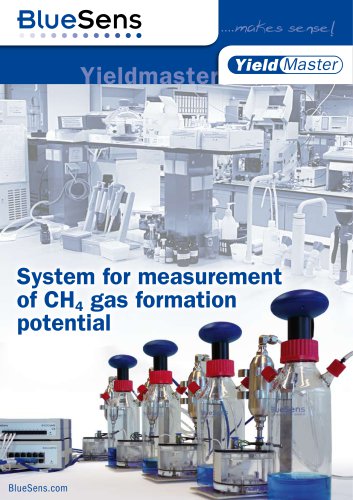

Yieldmaster

12 Pages

-

BCP-O2

8 Pages

-

In situ CO2 measurement

8 Pages

-

BlueVCount

2 Pages

Archived catalogs

-

H2 sensor BCP-H2

2 Pages

-

BlueVary

2 Pages

-

Brochure BlueInOne series

12 Pages

-

Brochure BCP-CO2 sensor

8 Pages

-

Data sheet BCP-O2

2 Pages

-

Data sheet BCpreFerm

8 Pages

-

BlueSens Brochure

6 Pages

-

Data Sheet BenchOne Biogas

2 Pages

-

BlueSens Report No.3

19 Pages

-

Brochure BlueSens 2012

6 Pages