Website:

BLOCK Electronics (Kunshan) Co., Ltd

Website:

BLOCK Electronics (Kunshan) Co., Ltd

Catalog excerpts

Future Winding The new dimension o f per for mance op t imiz a t ion o f induc t i ve w inding pr oduc t s L a nueva dimensión de op t imiz ación del r endimien t o de pr oduc t os de bobinado induc t i vo

Open the catalog to page 1

PProx Induc t i ve solu t ions for SiC , GaN – W ide bandgap t echnolog y ADVANTAGES OF THE NEW FUTURE WINDING TECHNOLOGY VENTAJAS DE LA NUEVA TECNOLOGÍA FUTURE WINDING BLOCK’s new in-house developed Future Winding technology is taking performance optimization of inductive winding products into a new dimension. The extraordinary variability in the design of the winding structure comes with a number of benefits for winding products: Optimal cooling by maximizing the heat-emitting conductor surface while also creating cooling ducts via the winding structure and minimal proximity losses with...

Open the catalog to page 2

LOW LOSSES Varying the conductor spacing in the winding structure effectively reduces proximity losses in the conductor that are generated by ripple currents from switching frequencies, particularly as frequency increases. This effect is significant, especially for future applications of SiC- and GaN-based semiconductor technologies. It also represents a potentially cost-effective alternative to the use of expensive high-frequency litz wires in conventional winding technologies. Variar el espaciado del conductor en la estructura de bobinado reduce de manera efectiva las pérdidas de...

Open the catalog to page 3

HIGH CURRENT DENSITY Due to the flexible design of the winding structure a maximum of the conductor’s heat-emitting surface is exposed to the prevailing cool air flow. The result is a high current density and efficient use of the conductive material (CU or AL), reducing structural volume, weight and costs. Debido al diseño flexible de la estructura de bobinado, un máximo de superficie de emisión de calor del conductor queda expuesto al actual flujo de aire fresco. El resultado es una densidad de corriente alta y un uso eficiente del material conductivo (CU o AL), lo que reduce el volumen,...

Open the catalog to page 4

FUTURE STANDARD LINE REACTORS REACTORES DE LÍNEA SINE FILTERS FILTROS SINUSOIDALES ALL-POLE SINE FILTERS FILTROS SINUSOIDALES OMNIPOLARES With the integration of the latest scientific findings in design and construction, alongside state-of-the-art winding and manufacturing technology, and the use of the winding material aluminium as a basis, BLOCK has been able to ensure an optimal price-performance ratio for the new product series. Con la integración de los más recientes hallazgos científicos en diseño y construcción, junto con tecnología de bobinado y fabricación de última generación,...

Open the catalog to page 5

A GLOBAL COMPANY UNA COMPAÑIA GLOBAL Headquarters and production sites Production sites International agencies Manufacturing Representatives Factory China BLOCK USA, Inc. 10632 W. Grand Avenue • Franklin Park, UL 60131 • USA Phone +1 847 260 9050 • Fax +1 847 260 9079 info@blockusa.com • www.blockusa.com

Open the catalog to page 6All BLOCK Electronics (Kunshan) Co. catalogs and technical brochures

-

TT3-A080-4040-0

2 Pages

-

TT3-A063-4040-0

2 Pages

-

TT3-A050-4040-0

2 Pages

-

TT3-A040-4040-0

2 Pages

-

TT3-A030-4040-0

2 Pages

-

TT3-A025-4040-0

2 Pages

-

TT3-A020-4040-0

2 Pages

-

TT3-A016-4040-0

2 Pages

-

TT3-A010-4040-0

2 Pages

-

POWER COMPACT CHAMP

4 Pages

-

ALL-POLE SINE FILTERS SF4

4 Pages

-

BLOCK POWER SUPPLIES

86 Pages

-

BLOCK COMPACT

80 Pages

-

RTE 30/2x24

2 Pages

-

RTE 20/2x24

2 Pages

-

RKD 30/2x24

2 Pages

-

RKD 20/2x24

2 Pages

-

ELECTRONIC CIRCUIT BREAKERS

6 Pages

-

SWITCHED MODE POWER SUPPLIES

6 Pages

-

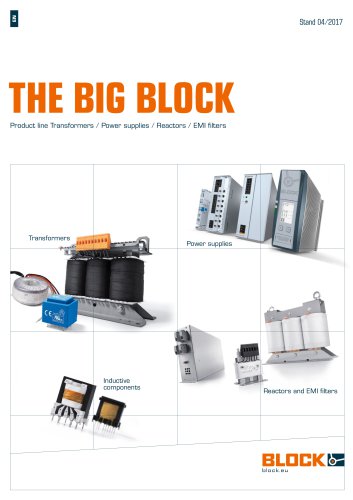

the big BLOCK

719 Pages

-

ALL ABOUT BLOCK

17 Pages