Catalog excerpts

Motion Without Limits Heavy Duty Track Roller Guidance System

Open the catalog to page 1

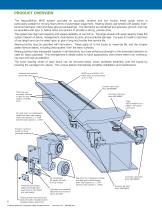

product overview The HepcoMotion MHD system provides an accurate, durable and low friction linear guide which is particularly suitable for moving heavy items of automation equipment. Bearing blocks use wheels with sealed, maintenance free taper roller and deep groove ball bearings. The flat tracks are hardened and precision ground, and may be specified with spur or helical racks and pinions to provide a strong, precise drive. The system has high load capacity and speed capability of over 6m/s. The large wheels with axial capacity make the system tolerant of debris, misalignment, disturbance...

Open the catalog to page 2

Motion Without Limits flat tracks MHD flat tracks are made from high quality carbon steel, surface hardened for maximum durability and precision ground on all flat faces. Tracks may be specified plain or with a MOD5 straight-cut rack or a MOD4 30° helical rack to ISO 1328 grade 10. Plain and straight rack cut flat tracks are made in fixed lengths of ~1.46m which are joined to produce unlimited runs*1. Other lengths can be supplied. All tracks are drilled and counterbored to suit fixing with M12 socket head cap screws*3. Installation is achieved by butting tracks end-to-end*1 against a...

Open the catalog to page 3

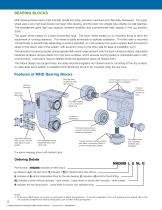

bearing blocks MHD bearing blocks have a high strength ductile iron body, precision machined and chemically blackened. The upper wheel uses a very high load double row taper roller bearing, and the lower two wheels have double row ball bearings. This arrangement gives high load capacity, excellent durability, and a predominant load capacity in the L1A direction (&6). The upper wheel rotates on a fixed (concentric) stud. The lower wheel rotates on an eccentric fixing to allow the adjustment of running clearance. This wheel is easily removable to facilitate installation. The third roller is...

Open the catalog to page 4

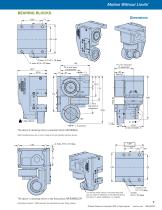

Motion Without Limits The above 6 drawings show a standard block MHD89BLE Right-handed blocks are a mirror image of the left-handed versions shown. The above 3 drawings show a rear fixing block MHD89BLER For the rear fixing version, the lower fixing bolt can be made to withdraw on the bearing side of the block, to assist installation, on request. dimensions marked * differ between the standard and rear fixing variants. © Bishop-Wisecarver Corporation 2008. All rights reserved.

Open the catalog to page 5

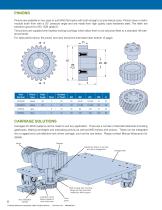

Pinions are available in two sizes to suit MHD flat tracks with both straight cut and helical racks. Pinions have a metric module tooth form with a 20° pressure angle and are made from high quality case hardened steel. The teeth are precision ground to ISO 1328 grade 6. The pinions are supplied with keyless locking bushings which allow them to be securely fitted to a standard h8 toler-anced shaft. For best performance, the pinion and rack should be lubricated (see bottom of page). Part Number CARRIAGE SOLUTiONS Carriages for MHD systems can be made to suit any application. There are a...

Open the catalog to page 6

Bearing Calculations The MHD system uses track roller bearings which run on a flat track. Due to the hardness of the track and the contact with the bearings, the track will not determine system life. The system life will be equivalent to the shortest bearing life. Bishop-Wisecaver quotes the basic life for each bearing, which corresponds to a linear travel of 1000km. The table also includes the expected bearing load for 10,000km of linear travel and the industry standard static (C0) and dynamic (C) load capacity figures*1. MHD block Basic load capacity Load for loading mode Bearing...

Open the catalog to page 7

Bishop-Wisecarver Corporation: Manufacturer of the original DualVee® guide wheel and industry leader in guided motion technology, and exclusive North and Central American partner and distributor for HepcoMotion products since 1984. BishopWisecarver Bishop-Wisecarver DualVee® GuideWheels LoPro® Linear Motion System MadeWell® Crown Rollers MinVee® Linear Slide System UtiliTrak® Linear Motion Guide 3D CAD DRAWINGS Download 3D CAD files for our complete product line at www.bwc.com/3dcad.php. GOT A TOUGH APPLICATION CHALLENGE? Ask Bud at www.bwc.com/blog/?cat=11. PRODUCT ORDERS Please call...

Open the catalog to page 8All BISHOP-WISECARVER catalogs and technical brochures

-

PSD80

12 Pages

-

PSD120

8 Pages

-

DAPDU2

2 Pages

-

EconoMotion®

2 Pages

-

DTS

12 Pages

-

DualVee

48 Pages

-

HepcoMotion® GV3

56 Pages

-

HDS2

52 Pages

-

HDLS

16 Pages

-

HDRT

24 Pages

-

HTS

38 Pages

-

MadeWell

12 Pages

-

PDU 2

2 Pages

-

HepcoMotion ® PDU2M

4 Pages

-

HepcoMotion

12 Pages

-

SL2

28 Pages

-

UtiliTrak Series

64 Pages

-

INNOVATION IS EVOLUTIONARY

3 Pages

-

Signature Motion ECO60

3 Pages

-

Signature Motion SlickStick

3 Pages

-

MadeWell®

2 Pages

-

DTS Driven Track System

12 Pages

-

UtiliTrak® Linear Motion Guide

16 Pages

-

QuickSelect Guide

44 Pages

Archived catalogs

-

GV3 Linear Guidance

56 Pages

-

DualVee Motion Technology

32 Pages

-

PDU2 Profile Driven Unit

2 Pages

-

DLS Driven Linear System

28 Pages

-

MinVee Catalog

4 Pages