Catalog excerpts

Motion Without Limits HDS2 Heavy Duty Slide System BishopWiseca

Open the catalog to page 1

System Composition - Application Examples - Full Size Illustrations for Initial Selection Data and Dimensions for Individual Components V Slides & Flat Tracks Back Plates Bearings Construction Beams Bumper Units Assembled Beams Carriages Rack Driven Carriages Drive Flange Assembly AC Geared Motors Bearing Cap Wipers Roller Cap Wipers Lubricators Pinions Automatic Rack Lubrication Lubrication Accessories - Bearing Blocks - Technical Data Data and Dimensions for Assembled Systems Load Life Calculations - Matched Systems - Mix & Match Component Compatibility Installation - Technical...

Open the catalog to page 2

HepcoMotion® H0S2 Heavy Duty Slide System, ava^able from Bishop-Wisecarver, retains the best features from the previous HDS product fine, and inoorporates them in o greatly expanded range. Many new components have been added including larger bearings with increased load capacity, two sizes of construction beam, single edge V siides and flbt track, as weff as a range of drive options. All this, with an option for stoiniess steei or corrosion resistant components, enables the HDS2 range to offer a solution for most customers' applications. Customers can choose from low cost commercial slides...

Open the catalog to page 3

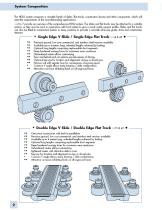

The HDS2 s/item comprises □ versatile family of slides, flot tracks, construction beams and other components, which will meet the requirements of the most demanding applications. 2 to 7 provide an overview of the comprehensive HDS2 system The slides and flat tracks may be attached to a suitable section, or they may be used in conjunction with back plates to give a ready made support profile. Slides and flat tracks can also be fitted to construction beams in many positions to provide a versatile all-in-one gui de, d rive and construction element. Precision ground, low cost commercial, and...

Open the catalog to page 4

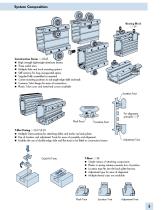

Bearing & Roller common features 18-21 *• Special raceway conformity arid low radial clearance. For slide applications Double row bearings For tolerance of debris and high load capacity Load capacity up to 50kN each Can be installed and removed without disengaging the carriage Nitule sealed Foi lifetime lubrication, inhibits ingress of liquids and contaminants All options available in stainless steel Permits out of parallel installation Crowned contact Face to overcome misalignment Th rough hole fixing ■ Bolt lengths to suit plate thickness From 7 to 40mm ■ Concentric (fixed) or eccentric...

Open the catalog to page 5

*• Spaces V slide and flat track away from mounting surface to allow the use of bearings., rollers and cap wipers *• Male key for location on V slide and flat tracks ** Female keyway for location using customer own key section or dowel pins ■ High wide & high narrow back plates available 16-17 to suit slides with bearing blocks 39

Open the catalog to page 6

Construe Hc>n B«tim 22-25 ■ High strength lighttight aluminum beams ■ Three useful sizes ■ Multiple slide and track mounting options ■ Stiff sections for long un sup ported spans ■ Supplied fully assembled as required ■ Corner mounting positions to suit single edge slide and track ■ Common T-slot design for ease of connections ■ Plastic T-slot cover and metal end covers available T-Slot Fixing 16,17 & 25 ■ Multiple T-slot positions for attaching slides and tracks via back plates ■ Use of location and adjustment T-nuts for ease of assembly and alignment ■ Enables the use of double edge slide...

Open the catalog to page 7

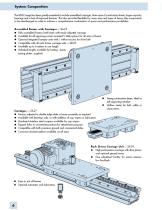

The FIDS2 range lias been greatly extended to include assembled carriages, three sizes of construction beam. Larger capacity bearings and a host oF improved Features. This also provides flexibility for many sizes and types of heavy duty components to be interchanged in order to achieve a comprehensive combination oF space and performance possibilities. Assembled Beams with Carriages 24-25 ■ Fully assembled factory built beam with ready adjusted carriage ■ Available for all opposing corner mounted V slide options for all sizes of beam ■ Optional integrated bumper units with / without access...

Open the catalog to page 8

HDCS - Heavy Duty Compact Strew Driven Unit ■ High performance linear transmission ■ High capacity, high precision ■ Compact high strength aluminum beam ■ Play free b allscrew. allows accurate positioning ■ Ballscrew lubrication point ■ Optional bellows cover ■ Easy fitting for limit switches ■ Integrated bumpers Heavy Duty Ring Slides and Track Systems - HDRT ■ Ring and segment sizes from 0512 to 01656mm ■ Ring slides with internal, extern at and opposing V's ■ Ring segments and gear cut options available ■ Track systems with fixed center or bogie carriages Not detailed in th is catalog....

Open the catalog to page 9

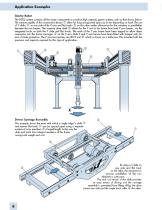

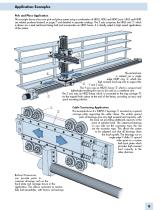

Gantry Robot The HDS2 system contains all the major components to produce high capacity gantry systems such as that shown below. The extreme frigidity of the construction beams i-' allow for long unsupported spans up to 6m depending on load. The use of V siiides (2 on one side of the X axis and flat tracks © on the other makes allowances for the variation in parallelism between the two beams The common drive shaft © allows For the Y axis to be driven from both X axis beams, via the integrated racks on both, the V slide and Flat tracks The ends of the Y axis beam have been tapped to allow...

Open the catalog to page 10

The vertical axis is rotated via a single edge HDRT ring which has _ high moment load capacity to support the Y and Z axes. The Y axis uses an HR25C beam 3 which is compact and lightweight enabling this axis to be used as a cantilever arm. The Z axis uses an HR25 beam which is connected to the ring carriage 3 via the tapped hole option at the end of the beam, providing an easy and quick mounting solution. Cable Tensioning Application This examp le sh ows 3 x THJ R 95 V he a ri ngs © mo u n ted on a speci al carriage plate supporting the cable clamp. The widely spaced pairs of bearings...

Open the catalog to page 11

Full size illustrations of the basic V slide systems and flat track systems and load capacities are shown on this and the following three pages as a guide to facilitate initial selection. Once a choice has been made., customers should refer to individual component pages for dimensions and to 42-44 for comprehensive details on load and life. Combinations other than shown in this section are possible. Please refer to the Mix & Match tables on 46-47 A wide range of other components complementary to the V slide systems and flat track systems are illustrated on the system composition 2-7 cross...

Open the catalog to page 12All BISHOP-WISECARVER catalogs and technical brochures

-

PSD80

12 Pages

-

PSD120

8 Pages

-

DAPDU2

2 Pages

-

EconoMotion®

2 Pages

-

DTS

12 Pages

-

DualVee

48 Pages

-

HepcoMotion® GV3

56 Pages

-

HDLS

16 Pages

-

HDRT

24 Pages

-

HTS

38 Pages

-

MadeWell

12 Pages

-

PDU 2

2 Pages

-

HepcoMotion ® PDU2M

4 Pages

-

HepcoMotion

12 Pages

-

SL2

28 Pages

-

UtiliTrak Series

64 Pages

-

INNOVATION IS EVOLUTIONARY

3 Pages

-

Signature Motion ECO60

3 Pages

-

Signature Motion SlickStick

3 Pages

-

MadeWell®

2 Pages

-

DTS Driven Track System

12 Pages

-

UtiliTrak® Linear Motion Guide

16 Pages

-

QuickSelect Guide

44 Pages

Archived catalogs

-

GV3 Linear Guidance

56 Pages

-

DualVee Motion Technology

32 Pages

-

PDU2 Profile Driven Unit

2 Pages

-

DLS Driven Linear System

28 Pages

-

MinVee Catalog

4 Pages