Website:

BinMaster

Website:

BinMaster

Catalog excerpts

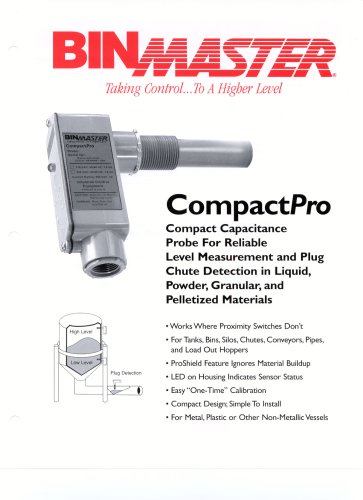

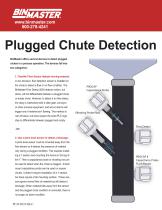

Plugged Chute Detection BinMaster offers several devices to detect plugged chutes in a process operation. The devices fall into two categories: 1. Flow/No Flow Sensor detects moving material: A non-intrusive, flow detection sensor is installed on the chute to detect a flow or no flow condition. The BinMaster Flow Detect 2000 detects motion, but PROCAP Capacitance Probe alone, will not differentiate between a plugged chute or empty chute. However, to detect a no flow status, the relay is interlocked with a slide gate, conveyor or other process equipment, and set so alarms will trigger only if material isn’t flowing. This method is non-intrusive, but does require the extra PLC logic Vibrating Probe/Rod step to differentiate between plugged and empty. -OR- Flow Detect 2. Use a point level sensor to detect a blockage: A point level sensor must be mounted away from the flow stream so it detects the presence of material only during a plugged condition. This requires installing a Y section and mounting the device in the leg of the Y. Then a capacitance probe or vibrating rod can be used to detect when the chute is clogged. A flush mount capacitance probe can be used on square chutes. It doesn’t require installation of a Y section, but does require a flat mounting surface. These sensors ignore normal flow of material but will detect a blockage. When material falls away from the sensor and the plugged chute condition is corrected, there is no longer an alarm condition. PROCAP II Capacitance Probe Flush Moun

Open the catalog to page 1All BinMaster catalogs and technical brochures

-

FeedView brochure

4 Pages

-

CNCR-400 Brochure

2 Pages

-

BMRX-300 Brochure

4 Pages

-

Full Line Brochure

24 Pages

-

NCR-86 Full Line Brochure

8 Pages

-

SmartSonic Brochure

8 Pages

-

Mini Rotary Brochure

2 Pages

-

3D Angled Mounting Flange

1 Pages

-

DPM-100 Display Brochure

2 Pages

-

DPM-200 Display Brochure

2 Pages

-

FVL-200 Brochure

4 Pages

-

SPL-200 Brochure

4 Pages

-

Tilt Switch Brochure

2 Pages

-

C-100 Display Brochure

2 Pages

-

Capacitance Probe Brochure

12 Pages

-

BMRX-200 Brochure

2 Pages

-

BMRX-100 Basic Rotary

2 Pages

-

GWR-3000 brochure

2 Pages

-

Vibrating Rod - 90

2 Pages

-

Vibrating Fork brochure

2 Pages

-

Airbrator

2 Pages

-

Vibrating Rod 90

2 Pages

-

Rotary Product Line Brochure

8 Pages

-

ProCap HD Brochure

1 Pages

-

Capacitance 101

2 Pages

-

BinMaster DPM-300

8 Pages

-

Flow Detect 2000

2 Pages

-

GWR-2000 Guided Wave Radar

4 Pages

-

Adjustable Rotary

1 Pages

-

MultiBob System Brochure

8 Pages

-

CVR-600 Mini Vibrating Rod

2 Pages

Archived catalogs

-

Full Line Product Catalog

24 Pages

-

CNCR Non-Contact Radar

12 Pages

-

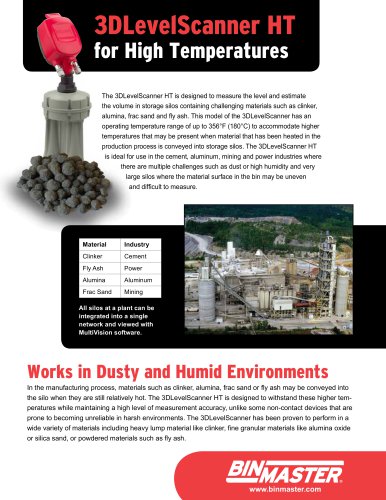

3DLevelScanner

8 Pages

-

Full Line Catalog

24 Pages

-

Airpad

2 Pages

-

Vibrating Fork 95

2 Pages

-

NCR-84

4 Pages

-

NCR-25 & NCR-30 Brochure

4 Pages

-

Diffuser Air Pad Brochure

2 Pages

-

DPM-200 Digital Panel Meter

6 Pages

-

SmartBobII MUCM Brochure

2 Pages

-

NCR-80 Accessories Brochure

3 Pages

-

Mini Vibrating Rod

2 Pages

-

Digital Panel Meter Display

8 Pages

-

BinMaster DPM-200

6 Pages

-

BinMaster Rotary brochure

8 Pages

-

Get the Point

7 Pages

-

MND Modbus Network Display

3 Pages

-

DPM-100

8 Pages

-

Binventory Software Brochure

4 Pages

-

VR-0515-NPC

4 Pages

-

NCR-80 Options Brochure

3 Pages

-

NCR-80 Non-Contact Radar

4 Pages

-

3D Angled Mounting Adaptor

2 Pages

-

3D 0 Degree Mounting Flange

1 Pages

-

Mercury_Free Tilt Switch

2 Pages

-

Mini-Rotary Brochure

2 Pages

-

SmartBob2 MUCM Brochure

2 Pages

-

Dust Detect 1000 Brochure

2 Pages

-

Diaphragm Switch Brochure

2 Pages

-

COMPACTPRO Brochure

2 Pages

-

3D Technical Data Brochure

4 Pages

-

WT 19

3 Pages

-

WL 19

3 Pages

-

BinMaster Rotary Brochure

8 Pages

-

3D MultiVision Software

4 Pages

-

BinMaster Air Pad Brochure

2 Pages