Website:

BinMaster

Website:

BinMaster

Catalog excerpts

GET THE POINT CHOOSING THE POINT LEVEL SENSOR FOR YOUR APPLICATION Point level indicators are an affordable, accurate tool to measure and alert to inventory high and low levels. Easy to set up and configurable to fit a wide range of application needs, point level indicators are a must-have for a safe, efficient operation. This whitepaper details what users can expect from a point level device and explores point level options in the marketplace and considerations when choosing a sensor.

Open the catalog to page 1

Inventory management is all about inventory and controlling its related costs. Your job is to figure out just how much material you have on hand and the right time to bring in more. But your inventory is most likely stored in a large, dark, and often dusty vessel. Short of x-ray vision, you have no way to safely "see” what is actually in them. Fortunately, there are many devices available to help you accurately measure your inventory. One category of inventory monitoring technology is called point level. Point level indicators are an affordable stand-alone tool to alert when inventory has...

Open the catalog to page 2

controlling a process, or causing a work stoppage if a tank should become empty, the application calls for a fail-safe rotary. These rotaries continually self-diagnose, and in the event of a failure, send an immediate warning and instantaneous corrective response. Fail-safe models often have an LED light or other visual indicator on the unit for visual monitoring of the motor status. Rotaries are increasingly applied in new and innovative ways. For high level detection at the interior of a vessel, a vertical extension on a rotary can allow it to be extended as far as 12 feet down into the...

Open the catalog to page 3

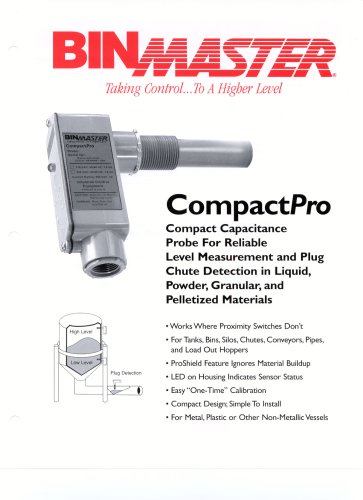

changes of less than one picofarad and operate at only 6 KHz, well below the RF level of most plant equipment. Since this type of capacitance sensor operates at such a low frequency, it will not interfere with nearby electronic plant equipment and is not susceptible to interference from other equipment. For food, feed, pharmaceutical, or chemical processing applications where the risk of contamination must be minimized, a shielded, Delrin-sleeved sanitary probe is often appropriate and will meet the regulatory requirements for the material application. A sanitary probe must be tested and...

Open the catalog to page 4

A flush mounted probe can be used in narrow or space-constrained areas or in applications where material flow or bridging may damage a standard probe. This type of probe mounts flush on the wall of the tank, on a conveyor housing, or in a chute. When mounted in tanks with thick walls or angled hoppers, a wall adapter is used to mount the probe flush or slightly protruding the inside of the vessel wall, which will help eliminate false signals due to excessive buildup on the probe surface. When the vessel is small or has internal obstructions, a bendable probe can be used to avoid...

Open the catalog to page 5

where material can become lodged and give a false signal, a vibrating rod features a single probe design that prevents material from bridging and giving a false signal. Vibrating level sensors are known for high performance and reliability and since the sensitivity is located at the tip of the sensor, material built up on the vessel wall will not influence the function of a vibrating level sensor. Plus, the combination of low energy and tip sensitivity reduces false alarms due to rat-holing around an active sensor. As the vibrating level sensor is piezoelectric, it can be used to overcome...

Open the catalog to page 6

Making the Right Choice When it comes to point level controls there is a robust selection of technologies at affordable prices starting at a few hundred dollars up to about a thousand dollars. Point level measurement is one critical piece in the level measurement puzzle that, when assembled correctly, will give you a clear picture of your inventory. ABOUT THE AUTHOR Jenny Christensen, MBA is the vice president of marketing for Garner Industries, home and manufacturer of BinMaster Level Controls.

Open the catalog to page 7All BinMaster catalogs and technical brochures

-

FeedView brochure

4 Pages

-

CNCR-400 Brochure

2 Pages

-

BMRX-300 Brochure

4 Pages

-

Full Line Brochure

24 Pages

-

NCR-86 Full Line Brochure

8 Pages

-

SmartSonic Brochure

8 Pages

-

Mini Rotary Brochure

2 Pages

-

3D Angled Mounting Flange

1 Pages

-

DPM-100 Display Brochure

2 Pages

-

DPM-200 Display Brochure

2 Pages

-

FVL-200 Brochure

4 Pages

-

SPL-200 Brochure

4 Pages

-

Tilt Switch Brochure

2 Pages

-

C-100 Display Brochure

2 Pages

-

Capacitance Probe Brochure

12 Pages

-

BMRX-200 Brochure

2 Pages

-

BMRX-100 Basic Rotary

2 Pages

-

GWR-3000 brochure

2 Pages

-

Vibrating Rod - 90

2 Pages

-

Vibrating Fork brochure

2 Pages

-

Airbrator

2 Pages

-

Vibrating Rod 90

2 Pages

-

Rotary Product Line Brochure

8 Pages

-

ProCap HD Brochure

1 Pages

-

Capacitance 101

2 Pages

-

BinMaster DPM-300

8 Pages

-

Flow Detect 2000

2 Pages

-

GWR-2000 Guided Wave Radar

4 Pages

-

Adjustable Rotary

1 Pages

-

MultiBob System Brochure

8 Pages

-

CVR-600 Mini Vibrating Rod

2 Pages

Archived catalogs

-

Full Line Product Catalog

24 Pages

-

CNCR Non-Contact Radar

12 Pages

-

3DLevelScanner

8 Pages

-

Full Line Catalog

24 Pages

-

Airpad

2 Pages

-

Vibrating Fork 95

2 Pages

-

NCR-84

4 Pages

-

NCR-25 & NCR-30 Brochure

4 Pages

-

Diffuser Air Pad Brochure

2 Pages

-

DPM-200 Digital Panel Meter

6 Pages

-

SmartBobII MUCM Brochure

2 Pages

-

NCR-80 Accessories Brochure

3 Pages

-

Mini Vibrating Rod

2 Pages

-

Digital Panel Meter Display

8 Pages

-

BinMaster DPM-200

6 Pages

-

BinMaster Rotary brochure

8 Pages

-

MND Modbus Network Display

3 Pages

-

DPM-100

8 Pages

-

Binventory Software Brochure

4 Pages

-

VR-0515-NPC

4 Pages

-

NCR-80 Options Brochure

3 Pages

-

NCR-80 Non-Contact Radar

4 Pages

-

3D Angled Mounting Adaptor

2 Pages

-

3D 0 Degree Mounting Flange

1 Pages

-

Mercury_Free Tilt Switch

2 Pages

-

Mini-Rotary Brochure

2 Pages

-

SmartBob2 MUCM Brochure

2 Pages

-

Dust Detect 1000 Brochure

2 Pages

-

Diaphragm Switch Brochure

2 Pages

-

COMPACTPRO Brochure

2 Pages

-

3D Technical Data Brochure

4 Pages

-

WT 19

3 Pages

-

WL 19

3 Pages

-

BinMaster Rotary Brochure

8 Pages

-

3D MultiVision Software

4 Pages

-

BinMaster Air Pad Brochure

2 Pages