Website:

Binks

Website:

Binks

Group: ITW Industrial finishing

Catalog excerpts

98-3230 36:1 AIR ASSIST PUMP ASSEMBLY SPECIFICATIONS

Open the catalog to page 1

EN In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows: Hazards or unsafe practices which could result in severe personal injury, death or substantial property damage. ! CAUTION Hazards or unsafe practices which could result in minor personal injury, product or property damage. Important installation, operation or maintenance information. Read the following warnings before using this equipment. READ THE MANUAL Before operating finishing equipment, read and understand all safety, operation and maintenance information provided...

Open the catalog to page 2

HIGH PRESSURE CAN CAUSE SERIOUS INJURY IF EQUIPMENT IS INSTALLED OR USED INCORRECTLY— READ, UNDERSTAND, AND OBSERVE ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL. INSTALL, OPERATE OR SERVICE THIS EQUIPMENT ONLY AFTER ALL INSTRUCTIONS ARE CLEARLY UNDERSTOOD. It is the responsibility of the employer to place this information into the hands of the operator. Hazards or unsafe practices which could result in severe personal injury, death or substantial property damage. Hazards or unsafe practices which could result in minor personal injury, product or property damage. AVOID STATIC SPARKING...

Open the catalog to page 3

_NOTE The pump is equipped with an air pressure safety valve. GROUNDING THE BINKS PUMP To prevent static charging igniting the flammable spray material, the BINKS pump must be grounded before it is started up. A grounding cable is included with the pump. 1. Clamp the grounding cable to the terminal on the high pressure filter or the air motor. 2. Connect the other end of the grounding cable to a suitable grounding device (e.g. grounding bar). PREPARING TO START UP THE BINKS PUMP Proceed as follows: 1. Check that the solvent cup is full to the level shown. If necessary, add material to the...

Open the catalog to page 5

|^E|CAUT!ON__ Once work is completed, the BINKS pump must be thoroughly cleaned. Under no circumstances must you allow paint residue to dry out in the unit. To clean the pump, use a solvent appropriate to the spray material. supply to 1 bar (14.5 psi). The pump will now draw in the spray material. The spray material flows back into the tank through the high pressure filter, the high pressure ball valve and the return pipe. 6. Remove the spray tip from the gun and point the gun into the tank. Unlock the safety lever on the gun. Operate the gun trigger and close the high pressure ball valve....

Open the catalog to page 6

EN MX3536 BARE PUMP ASSEMBLIES – MAINTENANCE MAINTENANCE SYMBOLS: # = MAINTENANCE ORDER Reverse for assembly

Open the catalog to page 8

May be used in place of check valve (#5).

Open the catalog to page 10

41-28362 STAINLESS STEEL FLUID FILTER ASSEMBLIESPARTS LIST ITEM NO.

Open the catalog to page 12

CART ASSEMBLY & WALL BRACKET ASSEMBLY 41-28343 CART ASSEMBLY 41-28335 WALL BRACKET ASSEMBLY PARTS LIST

Open the catalog to page 14

EN WARRANTY POLICY Binks products are covered by Carlisle Fluid Technologies one year materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. For specific warranty information please contact the closest Carlisle Fluid Technologies location listed below. Carlisle Fluid Technologies reserves the right to modify equipment specifications without prior notice. DeVilbiss®, Ransburg®, ms®, BGK®, and Binks® are registered trademarks of Carlisle Fluid Technologies, Inc. ©2018 Carlisle Fluid...

Open the catalog to page 16All Binks catalogs and technical brochures

-

AG-364

4 Pages

-

Premium Elevator Systems

7 Pages

-

RVC

2 Pages

-

AGMD PRO

2 Pages

-

AX200L AIR MOTOR ASSEMBLIES

10 Pages

-

BINKS MX SERIES

4 Pages

-

AA1600M

6 Pages

-

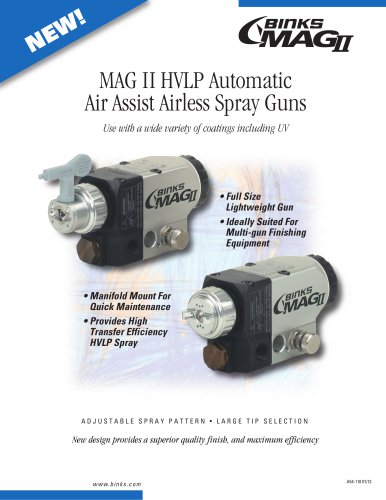

MAG II

4 Pages

-

2100

4 Pages

-

75

2 Pages

-

AG-363

2 Pages

-

GEMINI II Series

8 Pages

-

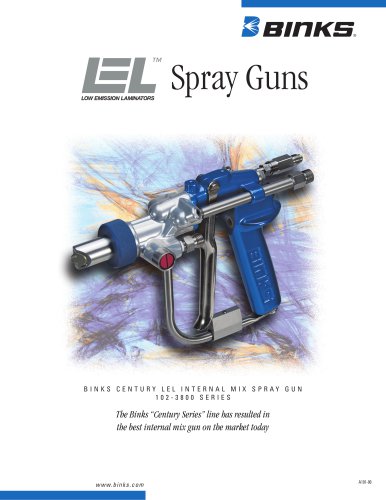

LEL Spray Guns

2 Pages

-

MX412

28 Pages

-

BINKS TROPHY SERIES

60 Pages

Archived catalogs

-

Rhino Automatic Spray Gun

1 Pages

-

Sun Skeeter

4 Pages

-

Magnalube-G

5 Pages

-

A-F High Efficiency Filter

3 Pages

-

Air Motor Oil - Motor Oil

7 Pages

-

Cleaner

5 Pages

-

Desiccant (air dryer)

4 Pages

-

Premium Desiccant

4 Pages

-

Lubricating Oil

4 Pages

-

White Booth Coat

6 Pages

-

Binks Pump Purj - Pump Purg

4 Pages

-

Watt Lube

3 Pages

-

Scrubs

4 Pages

-

A-F Filter

3 Pages

-

Wet Sol Plus

5 Pages

-

Spray Gun Lube

4 Pages

-

Booth Filter

4 Pages

-

spray vantage 3

2 Pages